Vertical grinder

- Production capacity: The model is 4100×2660×2620, 100-160 tons per hour

- Applicable materials: It can be used for final crushing of various materials such as mixture, gypsum, coal gangue, slag, copper ore, etc. It is also one of the crushing equipment commonly used in the compound fertilizer industry.

- Applications: It is suitable for the crushing of raw materials and returned materials, especially for materials with high moisture content, which is not easy to block.

Classification:

Tel:

Introduction

-

Vertical pulverizer is a professional organic fertilizer pulverizer carefully manufactured by our company's engineering researchers who have collected domestic and foreign pulverizing technology, and have repeatedly researched, improved and carefully manufactured with many years of production experience.

Effectively solve the problem of loose and broken organic matter with high water content. The successful development of the vertical pulverizer has played a key role in shortening the process flow, reducing equipment investment and saving operating costs for bio-organic fertilizer and composting.

-

The structure is composed of the lower frame, the casing, the upper and lower shaft seats, the main shaft, the hammer head, the hammer head bracket, the pulley, the motor frame, etc. The power drives the main shaft to rotate through the V-belt. The upper and lower ends of the casing, the casing assembly is installed on the lower frame, the hammer head and the hammer head bracket are installed on the main shaft, and the feeding hopper is installed on the upper part of the casing. repair.

Advantages of vertical crusher: The inner wall of the machine shell is lined with polypropylene plate, which alleviates the problem of sticking to the wall and difficult to clean. The chain cutter head is made of special steel linden, which can effectively improve production efficiency. Reasonable structure, convenient operation, strong applicability, etc.

-

Finished pellets

undefined

Features

-

- Commodity name: Vertical grinder

- Production capacity: The model is 4100×2660×2620, 100-160 tons per hour

- Applicable materials: It can be used for final crushing of various materials such as mixture, gypsum, coal gangue, slag, copper ore, etc. It is also one of the crushing equipment commonly used in the compound fertilizer industry.

- Applications: It is suitable for the crushing of raw materials and returned materials, especially for materials with high moisture content, which is not easy to block.

Vertical pulverizer is a professional organic fertilizer pulverizer carefully manufactured by our company's engineering researchers who have collected domestic and foreign pulverizing technology, and have repeatedly researched, improved and carefully manufactured with many years of production experience.

Effectively solve the problem of loose and broken organic matter with high water content. The successful development of the vertical pulverizer has played a key role in shortening the process flow, reducing equipment investment and saving operating costs for bio-organic fertilizer and composting.

-

The structure is composed of the lower frame, the casing, the upper and lower shaft seats, the main shaft, the hammer head, the hammer head bracket, the pulley, the motor frame, etc. The power drives the main shaft to rotate through the V-belt. The upper and lower ends of the casing, the casing assembly is installed on the lower frame, the hammer head and the hammer head bracket are installed on the main shaft, and the feeding hopper is installed on the upper part of the casing. repair.

Advantages of vertical crusher: The inner wall of the machine shell is lined with polypropylene plate, which alleviates the problem of sticking to the wall and difficult to clean. The chain cutter head is made of special steel linden, which can effectively improve production efficiency. Reasonable structure, convenient operation, strong applicability, etc.

-

Working Principle

-

- Commodity name: Vertical grinder

- Production capacity: The model is 4100×2660×2620, 100-160 tons per hour

- Applicable materials: It can be used for final crushing of various materials such as mixture, gypsum, coal gangue, slag, copper ore, etc. It is also one of the crushing equipment commonly used in the compound fertilizer industry.

- Applications: It is suitable for the crushing of raw materials and returned materials, especially for materials with high moisture content, which is not easy to block.

Vertical pulverizer is a professional organic fertilizer pulverizer carefully manufactured by our company's engineering researchers who have collected domestic and foreign pulverizing technology, and have repeatedly researched, improved and carefully manufactured with many years of production experience.

Effectively solve the problem of loose and broken organic matter with high water content. The successful development of the vertical pulverizer has played a key role in shortening the process flow, reducing equipment investment and saving operating costs for bio-organic fertilizer and composting.

-

The structure is composed of the lower frame, the casing, the upper and lower shaft seats, the main shaft, the hammer head, the hammer head bracket, the pulley, the motor frame, etc. The power drives the main shaft to rotate through the V-belt. The upper and lower ends of the casing, the casing assembly is installed on the lower frame, the hammer head and the hammer head bracket are installed on the main shaft, and the feeding hopper is installed on the upper part of the casing. repair.

Advantages of vertical crusher: The inner wall of the machine shell is lined with polypropylene plate, which alleviates the problem of sticking to the wall and difficult to clean. The chain cutter head is made of special steel linden, which can effectively improve production efficiency. Reasonable structure, convenient operation, strong applicability, etc.

-

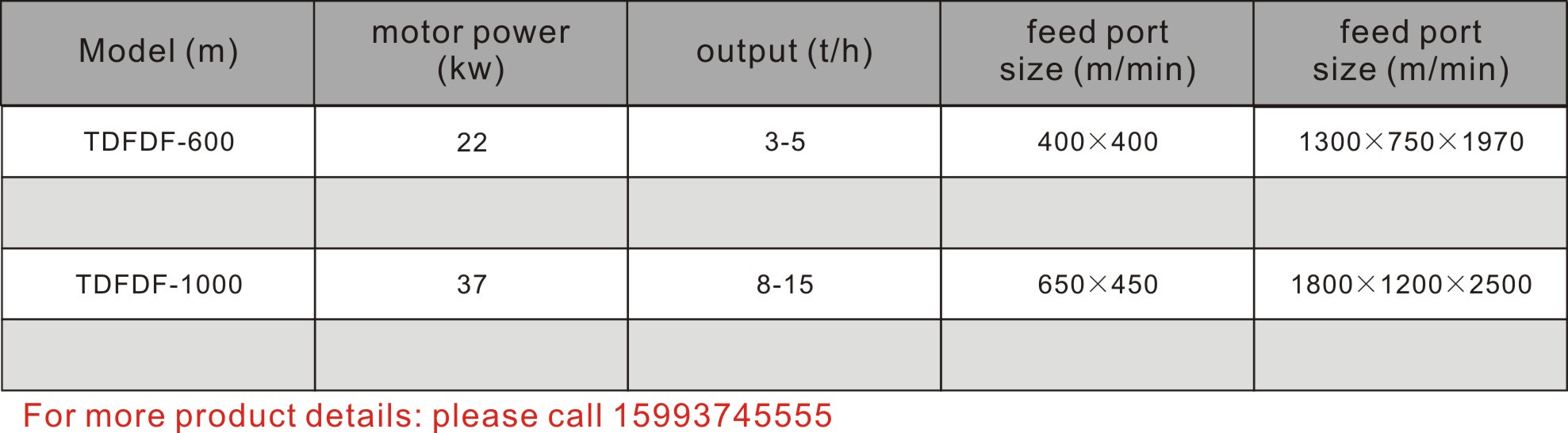

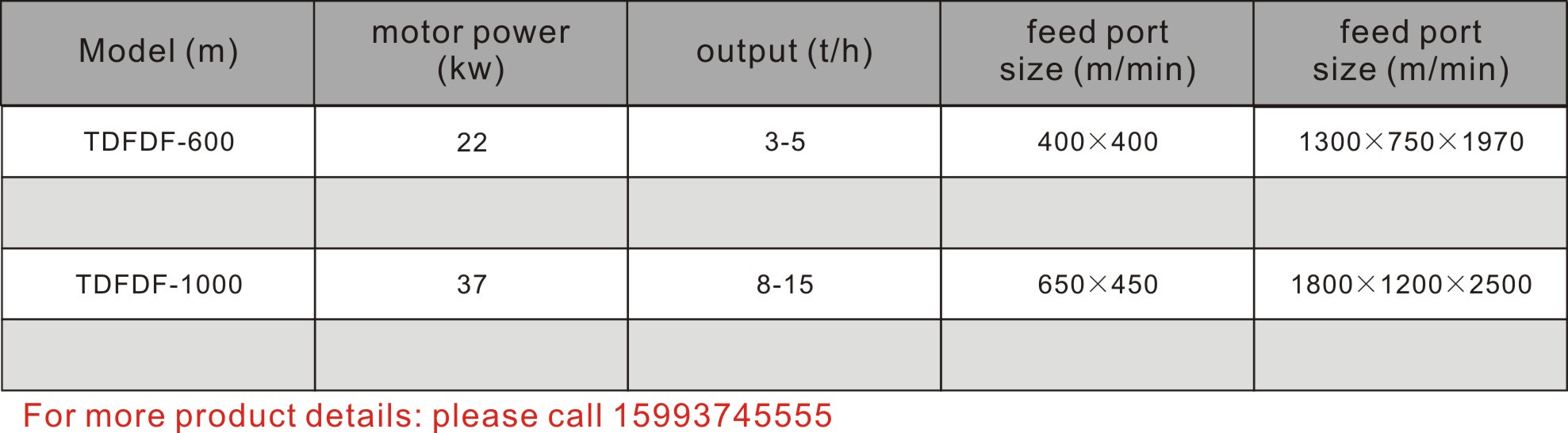

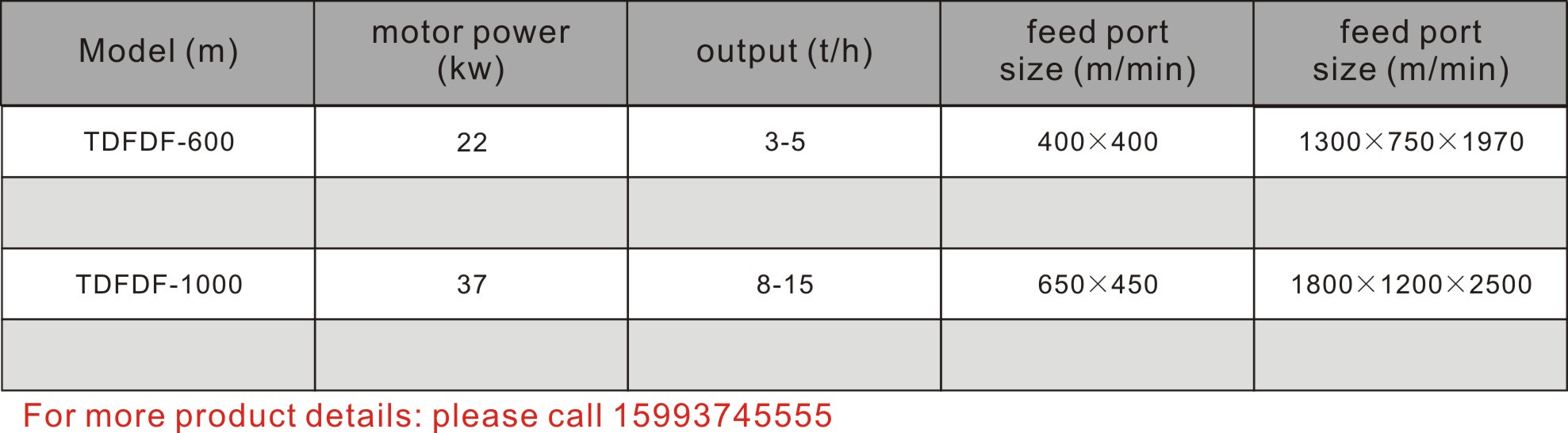

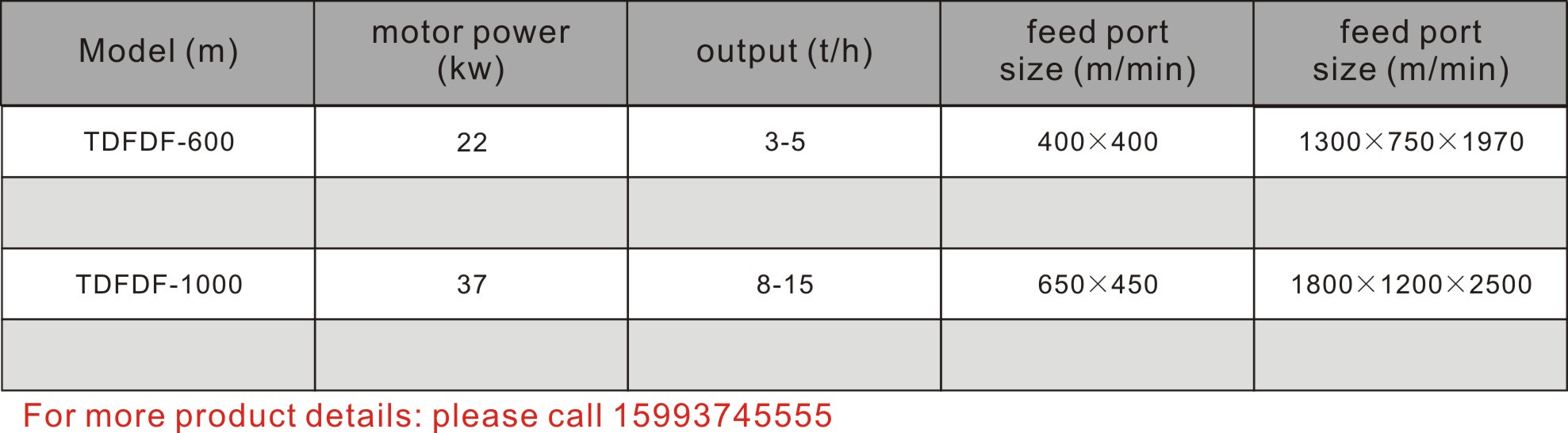

Technical parameters

-

- Commodity name: Vertical grinder

- Production capacity: The model is 4100×2660×2620, 100-160 tons per hour

- Applicable materials: It can be used for final crushing of various materials such as mixture, gypsum, coal gangue, slag, copper ore, etc. It is also one of the crushing equipment commonly used in the compound fertilizer industry.

- Applications: It is suitable for the crushing of raw materials and returned materials, especially for materials with high moisture content, which is not easy to block.

Vertical pulverizer is a professional organic fertilizer pulverizer carefully manufactured by our company's engineering researchers who have collected domestic and foreign pulverizing technology, and have repeatedly researched, improved and carefully manufactured with many years of production experience.

Effectively solve the problem of loose and broken organic matter with high water content. The successful development of the vertical pulverizer has played a key role in shortening the process flow, reducing equipment investment and saving operating costs for bio-organic fertilizer and composting.

-

The structure is composed of the lower frame, the casing, the upper and lower shaft seats, the main shaft, the hammer head, the hammer head bracket, the pulley, the motor frame, etc. The power drives the main shaft to rotate through the V-belt. The upper and lower ends of the casing, the casing assembly is installed on the lower frame, the hammer head and the hammer head bracket are installed on the main shaft, and the feeding hopper is installed on the upper part of the casing. repair.

Advantages of vertical crusher: The inner wall of the machine shell is lined with polypropylene plate, which alleviates the problem of sticking to the wall and difficult to clean. The chain cutter head is made of special steel linden, which can effectively improve production efficiency. Reasonable structure, convenient operation, strong applicability, etc.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry