Hammer Mill

- Production capacity: PC-0404 model, 2.5-5 tons per hour

- Applicable materials: The crushed materials are coal, salt, white, gypsum, bricks, limestone, etc.

- Applications: Suitable for medium hardness and Brittle materials are finely crushed

Classification:

Tel:

Introduction

-

When the hammer mill is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer head rushes to the baffle plate and sieve bar in the frame, and the material larger than the size of the sieve hole stays on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size and then discharged out of the machine through the sieve plate. . This machine is the best crushed product in the production of large-scale organic fertilizers.

-

Hammer mills mainly rely on impact to crush materials. The material enters the hammer mill and is crushed by the impact of the high-speed rotating hammer head. The crushed material obtains kinetic energy from the hammer head of the hammer crusher, and rushes to the baffle and screen bar in the frame at high speed. The materials collide with each other and are broken many times. The materials smaller than the gap between the screen bars are discharged from the gap, and the individual larger materials are impacted, ground, squeezed and broken by the hammer again on the screen bar, and the materials are crushed by the hammer. The hammer of the breaker is extruded from the gap. Thereby a product of the desired particle size is obtained.

-

Finished pellets

undefined

Features

-

- Commodity name: Hammer Mill

- Production capacity: PC-0404 model, 2.5-5 tons per hour

- Applicable materials: The crushed materials are coal, salt, white, gypsum, bricks, limestone, etc.

- Applications: Suitable for medium hardness and Brittle materials are finely crushed

When the hammer mill is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer head rushes to the baffle plate and sieve bar in the frame, and the material larger than the size of the sieve hole stays on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size and then discharged out of the machine through the sieve plate. . This machine is the best crushed product in the production of large-scale organic fertilizers.

-

Hammer mills mainly rely on impact to crush materials. The material enters the hammer mill and is crushed by the impact of the high-speed rotating hammer head. The crushed material obtains kinetic energy from the hammer head of the hammer crusher, and rushes to the baffle and screen bar in the frame at high speed. The materials collide with each other and are broken many times. The materials smaller than the gap between the screen bars are discharged from the gap, and the individual larger materials are impacted, ground, squeezed and broken by the hammer again on the screen bar, and the materials are crushed by the hammer. The hammer of the breaker is extruded from the gap. Thereby a product of the desired particle size is obtained.

-

Working Principle

-

- Commodity name: Hammer Mill

- Production capacity: PC-0404 model, 2.5-5 tons per hour

- Applicable materials: The crushed materials are coal, salt, white, gypsum, bricks, limestone, etc.

- Applications: Suitable for medium hardness and Brittle materials are finely crushed

When the hammer mill is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer head rushes to the baffle plate and sieve bar in the frame, and the material larger than the size of the sieve hole stays on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size and then discharged out of the machine through the sieve plate. . This machine is the best crushed product in the production of large-scale organic fertilizers.

-

Hammer mills mainly rely on impact to crush materials. The material enters the hammer mill and is crushed by the impact of the high-speed rotating hammer head. The crushed material obtains kinetic energy from the hammer head of the hammer crusher, and rushes to the baffle and screen bar in the frame at high speed. The materials collide with each other and are broken many times. The materials smaller than the gap between the screen bars are discharged from the gap, and the individual larger materials are impacted, ground, squeezed and broken by the hammer again on the screen bar, and the materials are crushed by the hammer. The hammer of the breaker is extruded from the gap. Thereby a product of the desired particle size is obtained.

-

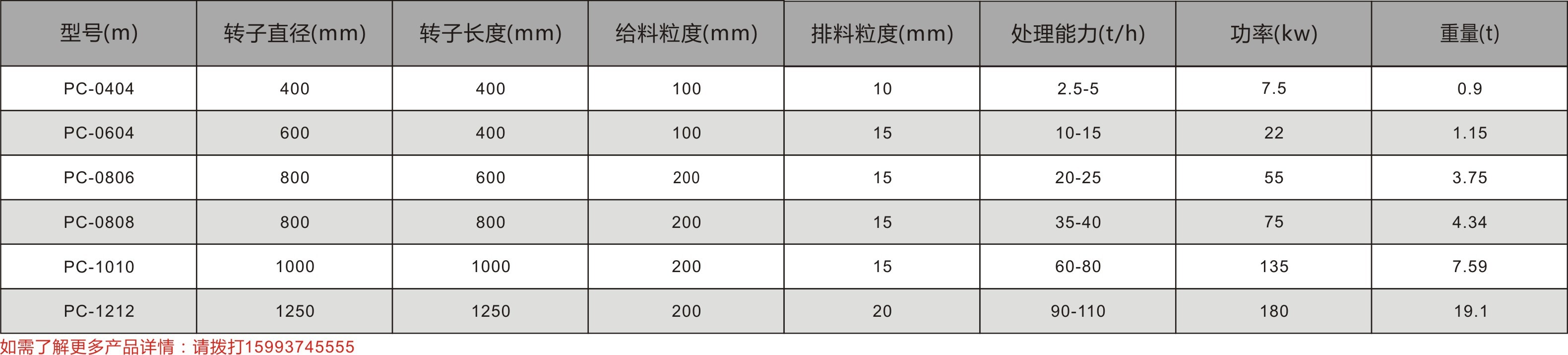

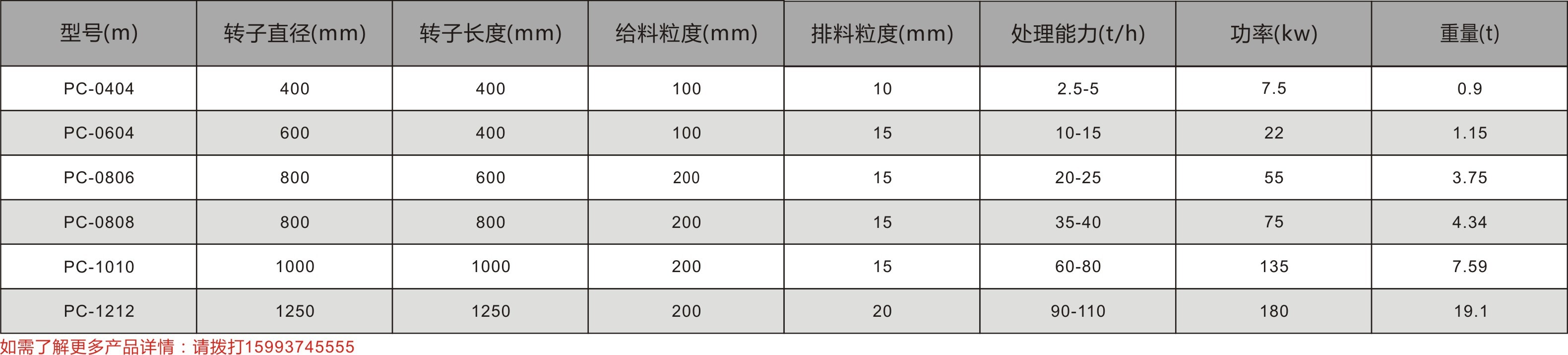

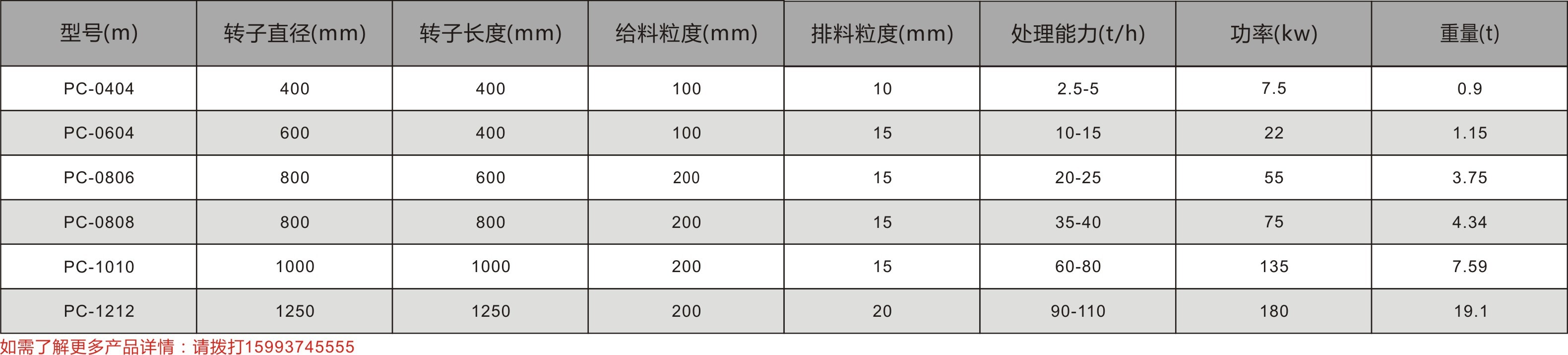

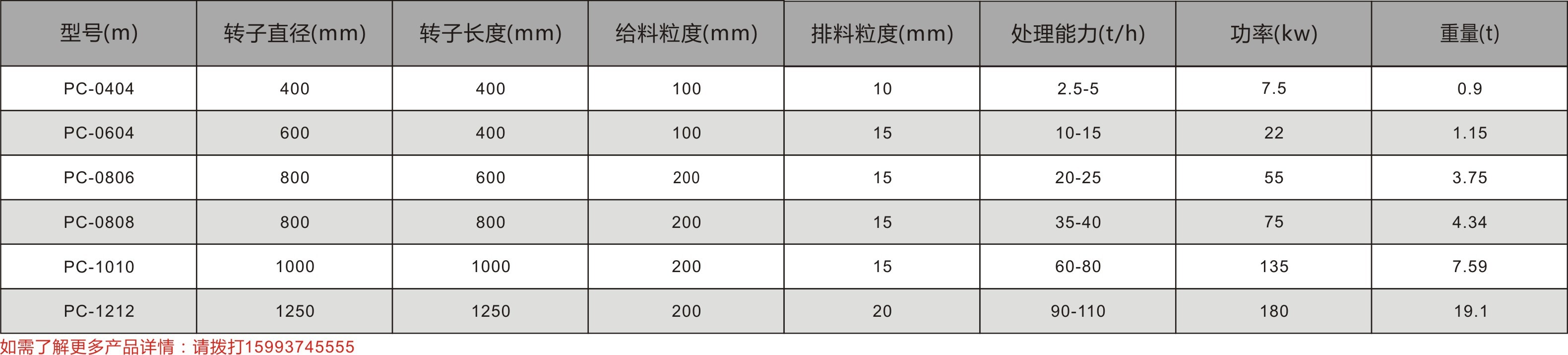

Technical parameters

-

- Commodity name: Hammer Mill

- Production capacity: PC-0404 model, 2.5-5 tons per hour

- Applicable materials: The crushed materials are coal, salt, white, gypsum, bricks, limestone, etc.

- Applications: Suitable for medium hardness and Brittle materials are finely crushed

When the hammer mill is working, the motor drives the rotor to rotate at a high speed, and the material enters the crusher cavity evenly. The high-speed rotating hammer head rushes to the baffle plate and sieve bar in the frame, and the material larger than the size of the sieve hole stays on the sieve plate and continues to be hit and ground by the hammer until it is crushed to the required discharge particle size and then discharged out of the machine through the sieve plate. . This machine is the best crushed product in the production of large-scale organic fertilizers.

-

Hammer mills mainly rely on impact to crush materials. The material enters the hammer mill and is crushed by the impact of the high-speed rotating hammer head. The crushed material obtains kinetic energy from the hammer head of the hammer crusher, and rushes to the baffle and screen bar in the frame at high speed. The materials collide with each other and are broken many times. The materials smaller than the gap between the screen bars are discharged from the gap, and the individual larger materials are impacted, ground, squeezed and broken by the hammer again on the screen bar, and the materials are crushed by the hammer. The hammer of the breaker is extruded from the gap. Thereby a product of the desired particle size is obtained.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry