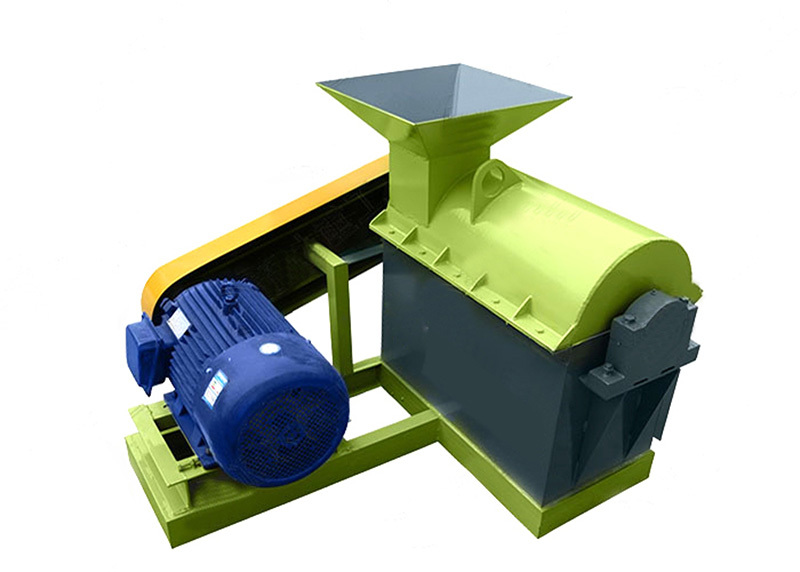

Semi-wet material pulverizer

- Production capacity: TDSF-120 model, 5-8 tons per hour

- Applicable materials: Bio-organic fermentation compost, municipal solid waste compost, grass peat, rural straw waste, industrial waste Machine waste, livestock and poultry manure, etc.

- Applications: Suitable for bio-organic fermentation compost.

Classification:

Tel:

Introduction

-

Semi-moist material pulverizer is used for bio-organic fermentation fertilizer, urban household waste compost, grass peat, rural straw waste, industrial organic waste, livestock breeding

Pulverization of biologically fermented high-humidity materials such as poultry excrement.

-

Semi-moist material pulverizer is a professional pulverizing equipment for pulverizing high-humidity, multi-fiber materials. The semi-wet material pulverizer uses high-speed rotating blades to pulverize fibers with good particle size and high efficiency. Semi-wet material pulverizers are mostly used in the production and processing of organic fertilizers, and have good results in pulverizing raw materials such as chicken manure and sodium humic acid.

1. The semi-wet material pulverizer adopts two-stage rotor for upper and lower pulverization. The material passes through the upper-stage rotor pulverizer into fine particles, and then is transported to the lower-stage rotor to continue to be pulverized into fine powder, which achieves the high level of material powder and hammer powder. efficiency, and then the discharge port is directly discharged.

2. The semi-wet material pulverizer is not designed with a screen bottom, and more than 100 kinds of materials can be pulverized without clogging. Even the material just picked up from the water can be crushed, and it will not be blocked due to the crushing of the wet material, which will cause the motor to burn out and affect the production.

3. The semi-wet material pulverizer adopts high-alloy wear-resistant hammer, and the hammer is made by forging, which is particularly strong and wear-resistant, which is stronger and more wear-resistant than ordinary hammer, which increases the service life of the hammer.

4. The semi-wet material pulverizer adopts two-way clearance adjustment technology. If the hammer is worn, it does not need to be repaired. It can continue to be used by moving the position of the hammer. The particle size of the material can be controlled by adjusting the gap between the hammer and the liner.

5. The semi-wet material pulverizer adopts high-tech technology, which can be easily operated by only one person, which is not only safe and reliable, but also easy to maintain.

6. The centralized lubrication system of the semi-wet material pulverizer is filled with oil. Under normal operation, lubricating oil can be injected without stopping the machine.

Finished pellets

undefined

Features

-

- Commodity name: Semi-wet material pulverizer

- Production capacity: TDSF-120 model, 5-8 tons per hour

- Applicable materials: Bio-organic fermentation compost, municipal solid waste compost, grass peat, rural straw waste, industrial waste Machine waste, livestock and poultry manure, etc.

- Applications: Suitable for bio-organic fermentation compost.

Semi-moist material pulverizer is used for bio-organic fermentation fertilizer, urban household waste compost, grass peat, rural straw waste, industrial organic waste, livestock breeding

Pulverization of biologically fermented high-humidity materials such as poultry excrement.

-

Semi-moist material pulverizer is a professional pulverizing equipment for pulverizing high-humidity, multi-fiber materials. The semi-wet material pulverizer uses high-speed rotating blades to pulverize fibers with good particle size and high efficiency. Semi-wet material pulverizers are mostly used in the production and processing of organic fertilizers, and have good results in pulverizing raw materials such as chicken manure and sodium humic acid.

1. The semi-wet material pulverizer adopts two-stage rotor for upper and lower pulverization. The material passes through the upper-stage rotor pulverizer into fine particles, and then is transported to the lower-stage rotor to continue to be pulverized into fine powder, which achieves the high level of material powder and hammer powder. efficiency, and then the discharge port is directly discharged.

2. The semi-wet material pulverizer is not designed with a screen bottom, and more than 100 kinds of materials can be pulverized without clogging. Even the material just picked up from the water can be crushed, and it will not be blocked due to the crushing of the wet material, which will cause the motor to burn out and affect the production.

3. The semi-wet material pulverizer adopts high-alloy wear-resistant hammer, and the hammer is made by forging, which is particularly strong and wear-resistant, which is stronger and more wear-resistant than ordinary hammer, which increases the service life of the hammer.

4. The semi-wet material pulverizer adopts two-way clearance adjustment technology. If the hammer is worn, it does not need to be repaired. It can continue to be used by moving the position of the hammer. The particle size of the material can be controlled by adjusting the gap between the hammer and the liner.

5. The semi-wet material pulverizer adopts high-tech technology, which can be easily operated by only one person, which is not only safe and reliable, but also easy to maintain.

6. The centralized lubrication system of the semi-wet material pulverizer is filled with oil. Under normal operation, lubricating oil can be injected without stopping the machine.

Working Principle

-

- Commodity name: Semi-wet material pulverizer

- Production capacity: TDSF-120 model, 5-8 tons per hour

- Applicable materials: Bio-organic fermentation compost, municipal solid waste compost, grass peat, rural straw waste, industrial waste Machine waste, livestock and poultry manure, etc.

- Applications: Suitable for bio-organic fermentation compost.

Semi-moist material pulverizer is used for bio-organic fermentation fertilizer, urban household waste compost, grass peat, rural straw waste, industrial organic waste, livestock breeding

Pulverization of biologically fermented high-humidity materials such as poultry excrement.

-

Semi-moist material pulverizer is a professional pulverizing equipment for pulverizing high-humidity, multi-fiber materials. The semi-wet material pulverizer uses high-speed rotating blades to pulverize fibers with good particle size and high efficiency. Semi-wet material pulverizers are mostly used in the production and processing of organic fertilizers, and have good results in pulverizing raw materials such as chicken manure and sodium humic acid.

1. The semi-wet material pulverizer adopts two-stage rotor for upper and lower pulverization. The material passes through the upper-stage rotor pulverizer into fine particles, and then is transported to the lower-stage rotor to continue to be pulverized into fine powder, which achieves the high level of material powder and hammer powder. efficiency, and then the discharge port is directly discharged.

2. The semi-wet material pulverizer is not designed with a screen bottom, and more than 100 kinds of materials can be pulverized without clogging. Even the material just picked up from the water can be crushed, and it will not be blocked due to the crushing of the wet material, which will cause the motor to burn out and affect the production.

3. The semi-wet material pulverizer adopts high-alloy wear-resistant hammer, and the hammer is made by forging, which is particularly strong and wear-resistant, which is stronger and more wear-resistant than ordinary hammer, which increases the service life of the hammer.

4. The semi-wet material pulverizer adopts two-way clearance adjustment technology. If the hammer is worn, it does not need to be repaired. It can continue to be used by moving the position of the hammer. The particle size of the material can be controlled by adjusting the gap between the hammer and the liner.

5. The semi-wet material pulverizer adopts high-tech technology, which can be easily operated by only one person, which is not only safe and reliable, but also easy to maintain.

6. The centralized lubrication system of the semi-wet material pulverizer is filled with oil. Under normal operation, lubricating oil can be injected without stopping the machine.

Technical parameters

-

- Commodity name: Semi-wet material pulverizer

- Production capacity: TDSF-120 model, 5-8 tons per hour

- Applicable materials: Bio-organic fermentation compost, municipal solid waste compost, grass peat, rural straw waste, industrial waste Machine waste, livestock and poultry manure, etc.

- Applications: Suitable for bio-organic fermentation compost.

Semi-moist material pulverizer is used for bio-organic fermentation fertilizer, urban household waste compost, grass peat, rural straw waste, industrial organic waste, livestock breeding

Pulverization of biologically fermented high-humidity materials such as poultry excrement.

-

Semi-moist material pulverizer is a professional pulverizing equipment for pulverizing high-humidity, multi-fiber materials. The semi-wet material pulverizer uses high-speed rotating blades to pulverize fibers with good particle size and high efficiency. Semi-wet material pulverizers are mostly used in the production and processing of organic fertilizers, and have good results in pulverizing raw materials such as chicken manure and sodium humic acid.

1. The semi-wet material pulverizer adopts two-stage rotor for upper and lower pulverization. The material passes through the upper-stage rotor pulverizer into fine particles, and then is transported to the lower-stage rotor to continue to be pulverized into fine powder, which achieves the high level of material powder and hammer powder. efficiency, and then the discharge port is directly discharged.

2. The semi-wet material pulverizer is not designed with a screen bottom, and more than 100 kinds of materials can be pulverized without clogging. Even the material just picked up from the water can be crushed, and it will not be blocked due to the crushing of the wet material, which will cause the motor to burn out and affect the production.

3. The semi-wet material pulverizer adopts high-alloy wear-resistant hammer, and the hammer is made by forging, which is particularly strong and wear-resistant, which is stronger and more wear-resistant than ordinary hammer, which increases the service life of the hammer.

4. The semi-wet material pulverizer adopts two-way clearance adjustment technology. If the hammer is worn, it does not need to be repaired. It can continue to be used by moving the position of the hammer. The particle size of the material can be controlled by adjusting the gap between the hammer and the liner.

5. The semi-wet material pulverizer adopts high-tech technology, which can be easily operated by only one person, which is not only safe and reliable, but also easy to maintain.

6. The centralized lubrication system of the semi-wet material pulverizer is filled with oil. Under normal operation, lubricating oil can be injected without stopping the machine.

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry