BCP series quantitative packaging scale

- Production capacity: 1-12t/h

- Applicable materials: Grain, feed, food, light industry, chemical industry, etc.

- Applications: Gasture, etc.

Classification:

Tel:

Introduction

-

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

1. The unique anti-vibration device ensures measurement accuracy, fast packing speed, and can work stably under complex working conditions.

2. The machinery is adjusted externally, which is convenient for maintenance.

3. The key components are imported, with long service life and strong anti-interference ability.

4. Modify the digital adjustment of the internal code of the drop at any time, and automatically track the zero position.

5. The belt feeding scale is suitable for the packaging of powdery materials and granular materials, and the screw feeding scale is only suitable for the packaging of powdery materials.

-

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

Finished pellets

undefined

Features

-

- Commodity name: BCP series quantitative packaging scale

- Production capacity: 1-12t/h

- Applicable materials: Grain, feed, food, light industry, chemical industry, etc.

- Applications: Gasture, etc.

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

1. The unique anti-vibration device ensures measurement accuracy, fast packing speed, and can work stably under complex working conditions.

2. The machinery is adjusted externally, which is convenient for maintenance.

3. The key components are imported, with long service life and strong anti-interference ability.

4. Modify the digital adjustment of the internal code of the drop at any time, and automatically track the zero position.

5. The belt feeding scale is suitable for the packaging of powdery materials and granular materials, and the screw feeding scale is only suitable for the packaging of powdery materials.

-

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

Working Principle

-

- Commodity name: BCP series quantitative packaging scale

- Production capacity: 1-12t/h

- Applicable materials: Grain, feed, food, light industry, chemical industry, etc.

- Applications: Gasture, etc.

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

1. The unique anti-vibration device ensures measurement accuracy, fast packing speed, and can work stably under complex working conditions.

2. The machinery is adjusted externally, which is convenient for maintenance.

3. The key components are imported, with long service life and strong anti-interference ability.

4. Modify the digital adjustment of the internal code of the drop at any time, and automatically track the zero position.

5. The belt feeding scale is suitable for the packaging of powdery materials and granular materials, and the screw feeding scale is only suitable for the packaging of powdery materials.

-

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

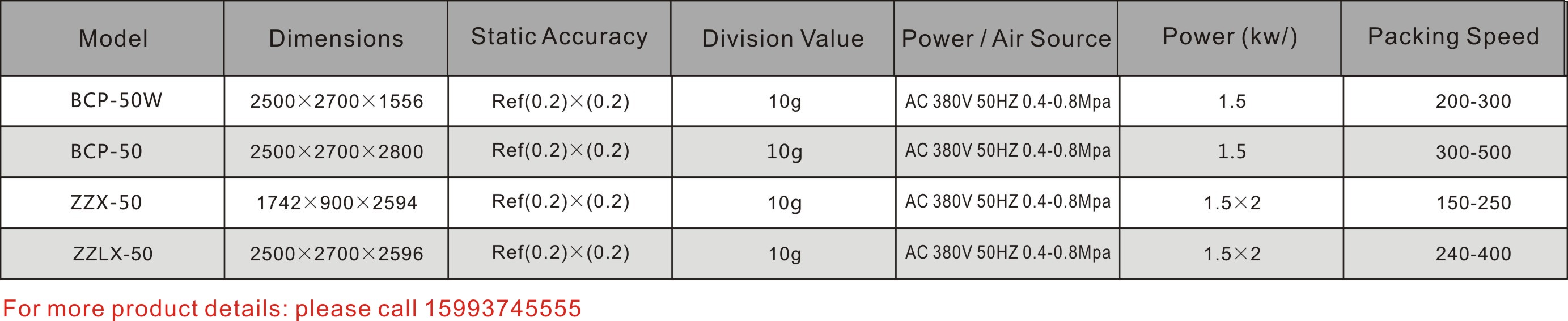

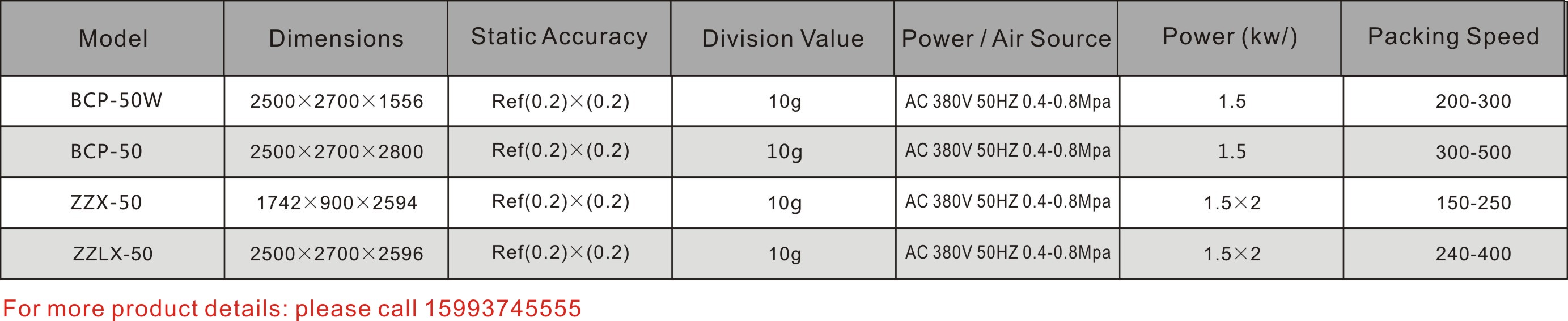

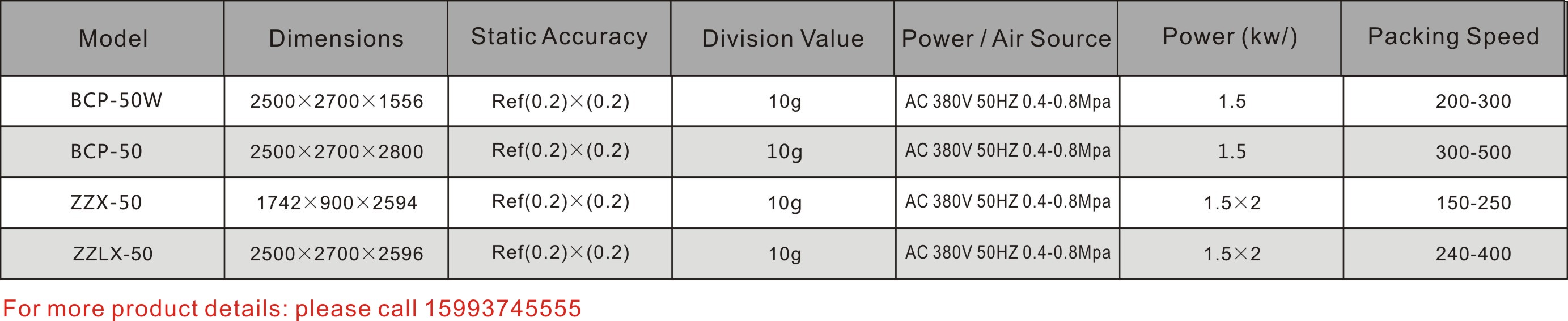

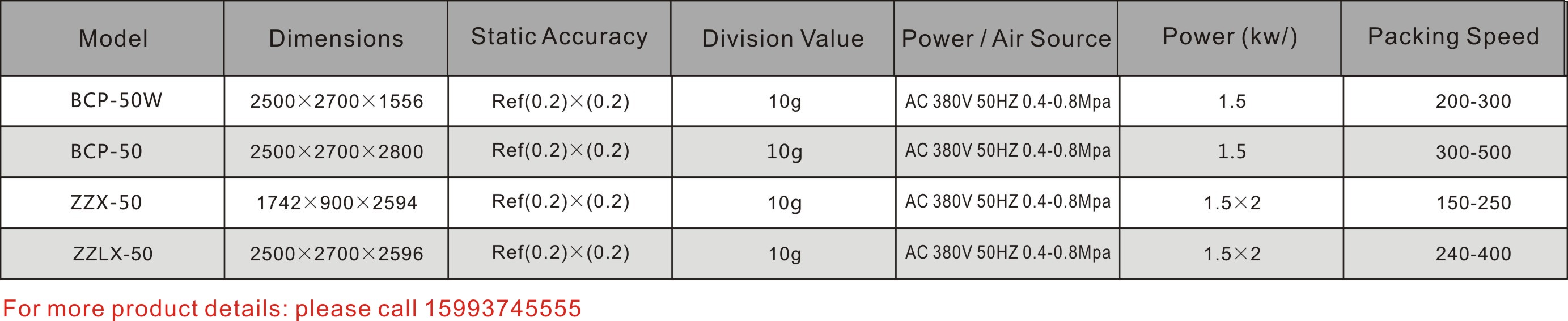

Technical parameters

-

- Commodity name: BCP series quantitative packaging scale

- Production capacity: 1-12t/h

- Applicable materials: Grain, feed, food, light industry, chemical industry, etc.

- Applications: Gasture, etc.

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

1. The unique anti-vibration device ensures measurement accuracy, fast packing speed, and can work stably under complex working conditions.

2. The machinery is adjusted externally, which is convenient for maintenance.

3. The key components are imported, with long service life and strong anti-interference ability.

4. Modify the digital adjustment of the internal code of the drop at any time, and automatically track the zero position.

5. The belt feeding scale is suitable for the packaging of powdery materials and granular materials, and the screw feeding scale is only suitable for the packaging of powdery materials.

-

Under the control of the weighing intelligent instrument, the packaging scale first performs coarse feeding. The instrument collects sensor signals. When the coarse measurement setting value is reached, the fine feeding is performed. When the impulse correction value is reached, the feeding is stopped. The material door is closed, and a weighing and unloading signal is sent. After receiving the unloading signal, the PLC asks whether the bag is clamped. If it is tightened, the unloading door is opened to discharge. After the signal is turned off, start the meter to enter the next package weighing.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry