HMQC Series Disc Crusher

- Production capacity: 1-20t/h

- Applicable materials: Shrubs, straws and bales, etc.

- Applications: Pasture, etc.

Classification:

Tel:

Introduction

-

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. Large-scale crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. The large crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

Finished pellets

undefined

Features

-

- Commodity name: HMQC Series Disc Crusher

- Production capacity: 1-20t/h

- Applicable materials: Shrubs, straws and bales, etc.

- Applications: Pasture, etc.

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. Large-scale crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. The large crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

Working Principle

-

- Commodity name: HMQC Series Disc Crusher

- Production capacity: 1-20t/h

- Applicable materials: Shrubs, straws and bales, etc.

- Applications: Pasture, etc.

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. Large-scale crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. The large crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

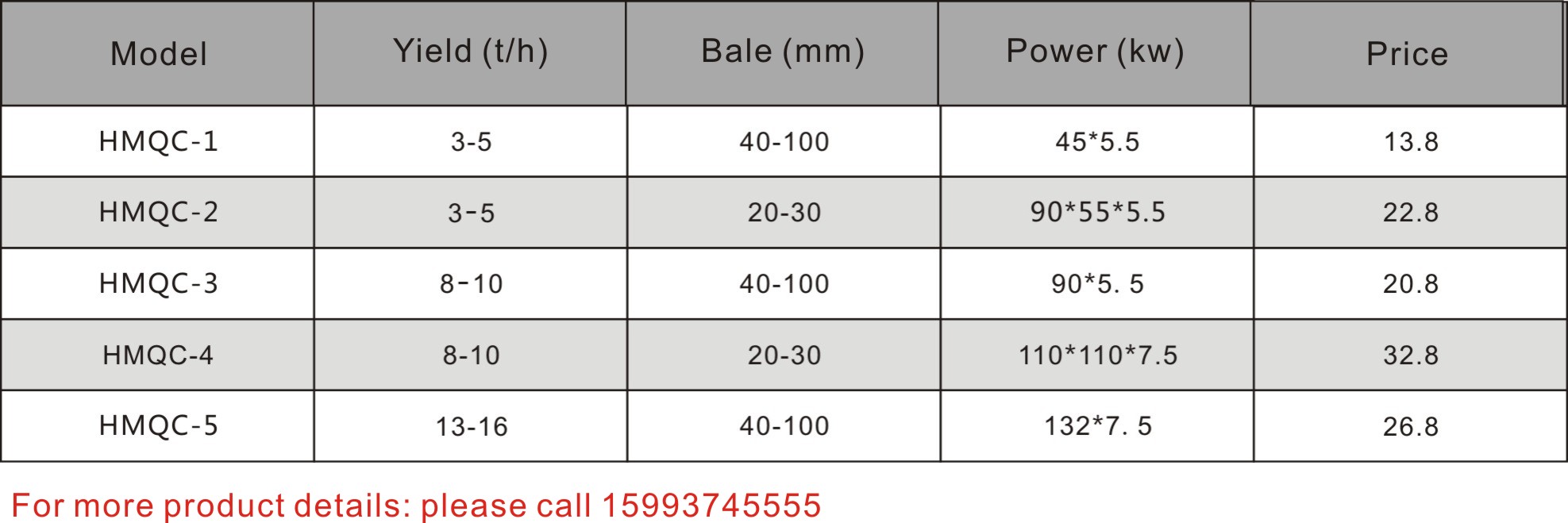

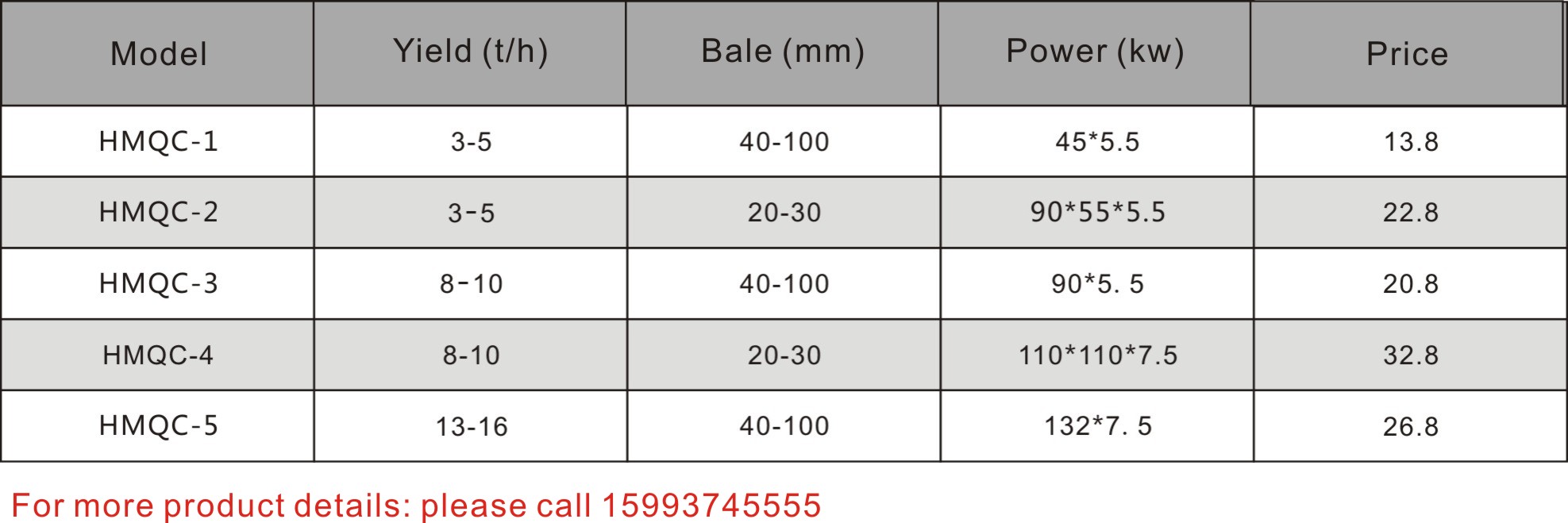

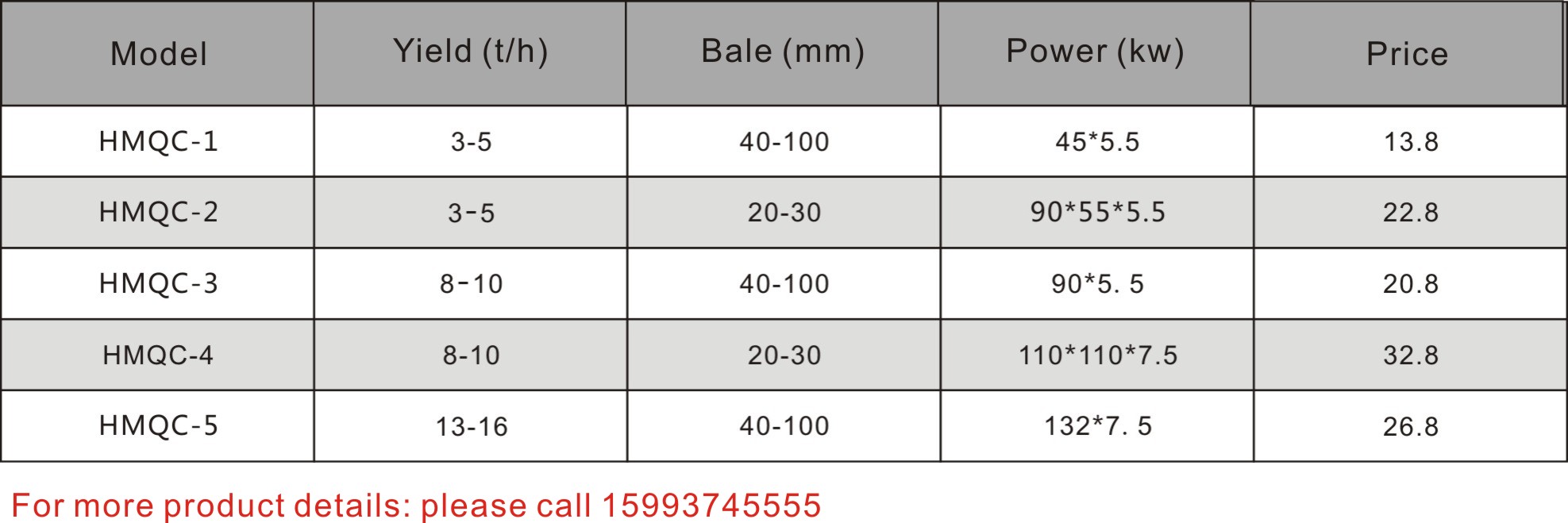

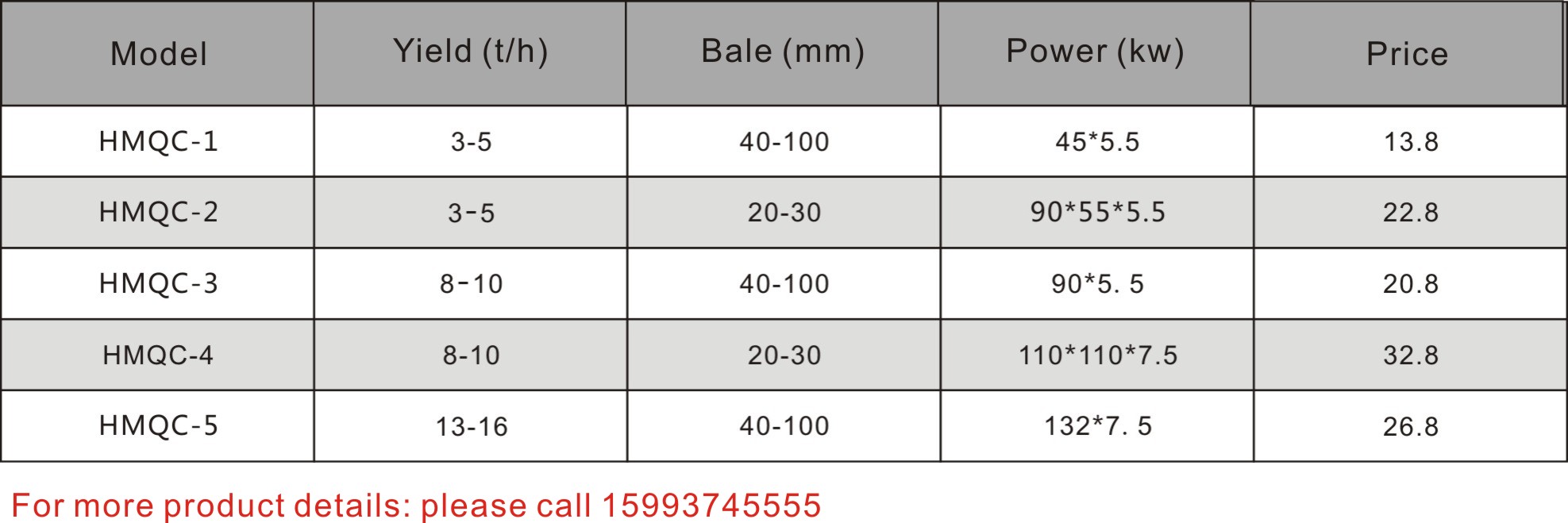

Technical parameters

-

- Commodity name: HMQC Series Disc Crusher

- Production capacity: 1-20t/h

- Applicable materials: Shrubs, straws and bales, etc.

- Applications: Pasture, etc.

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. Large-scale crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

Shrub, straw and straw bales are broken and coarsely crushed production process: grass grabber feeding - manual shearing, unpacking rope - uniform cloth - picking up debris - broken bales and coarse crushing.

In order to solve the problem of traditional crusher crushing shrubs, straw materials are difficult to feed, and the output is low. The large crusher is suitable for straw and grass materials. Features: grass grabber or belt conveyor feeding, feeding bin 5-10 Cube, frequency conversion control, two structures of crushing chamber, one is single rotor for coarse crushing and bundling, the second is double rotor which is divided into coarse crushing chamber and fine crushing chamber. degree requirements.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry