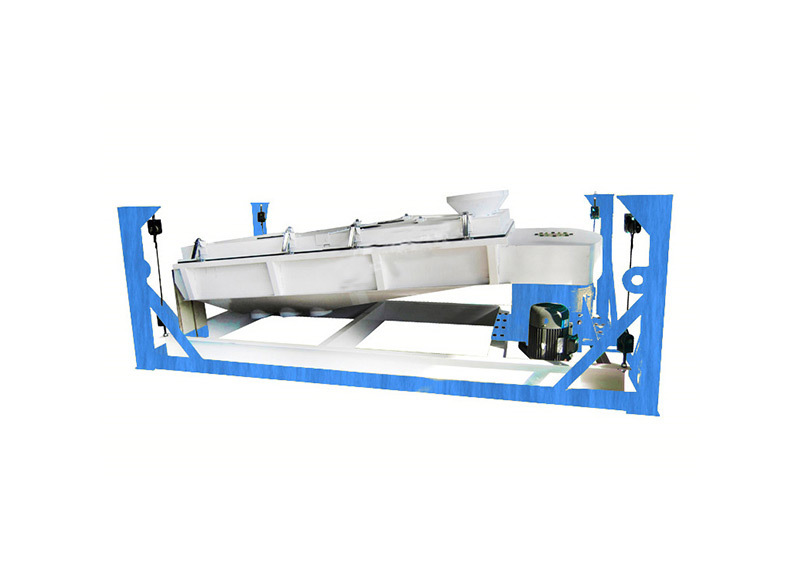

SFJH series rotary classifier

- Production capacity: 3-15t/h

- Applicable materials: Grain, food, chemical, sugar, mining, paper

- Applications: Geed mill, etc.

Classification:

Tel:

Introduction

-

The power is transmitted from the motor to the drive device through the V-belt, and the drive device drives the screen body with a certain slope to move. The drive device is equipped with an eccentric device, so the movement track of the screen body from the feed end to the discharge end gradually changes from a horizontal circular motion to an elliptical motion, and becomes an approximate reciprocating linear motion. The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

1. It is suitable for the classification of granular materials and crushed materials and the secondary circulation crushing process.

2. Adopting the eccentric balance mechanism and elastic tail support mechanism driven by V-belt, the material rotates on the working surface of the horizontal rotating body, the screening efficiency is high, and the vibration is small.

3. The internal streamline design of the discharge port prevents material deposition and avoids cross-contamination.

4. The sieve pressing mechanism is firm and the sieve can be changed quickly.

5. Single-layer screen, two-layer screen and three-layer screen can be customized according to needs.

-

The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

Finished pellets

undefined

Features

-

- Commodity name: SFJH series rotary classifier

- Production capacity: 3-15t/h

- Applicable materials: Grain, food, chemical, sugar, mining, paper

- Applications: Geed mill, etc.

The power is transmitted from the motor to the drive device through the V-belt, and the drive device drives the screen body with a certain slope to move. The drive device is equipped with an eccentric device, so the movement track of the screen body from the feed end to the discharge end gradually changes from a horizontal circular motion to an elliptical motion, and becomes an approximate reciprocating linear motion. The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

1. It is suitable for the classification of granular materials and crushed materials and the secondary circulation crushing process.

2. Adopting the eccentric balance mechanism and elastic tail support mechanism driven by V-belt, the material rotates on the working surface of the horizontal rotating body, the screening efficiency is high, and the vibration is small.

3. The internal streamline design of the discharge port prevents material deposition and avoids cross-contamination.

4. The sieve pressing mechanism is firm and the sieve can be changed quickly.

5. Single-layer screen, two-layer screen and three-layer screen can be customized according to needs.

-

The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

Working Principle

-

- Commodity name: SFJH series rotary classifier

- Production capacity: 3-15t/h

- Applicable materials: Grain, food, chemical, sugar, mining, paper

- Applications: Geed mill, etc.

The power is transmitted from the motor to the drive device through the V-belt, and the drive device drives the screen body with a certain slope to move. The drive device is equipped with an eccentric device, so the movement track of the screen body from the feed end to the discharge end gradually changes from a horizontal circular motion to an elliptical motion, and becomes an approximate reciprocating linear motion. The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

1. It is suitable for the classification of granular materials and crushed materials and the secondary circulation crushing process.

2. Adopting the eccentric balance mechanism and elastic tail support mechanism driven by V-belt, the material rotates on the working surface of the horizontal rotating body, the screening efficiency is high, and the vibration is small.

3. The internal streamline design of the discharge port prevents material deposition and avoids cross-contamination.

4. The sieve pressing mechanism is firm and the sieve can be changed quickly.

5. Single-layer screen, two-layer screen and three-layer screen can be customized according to needs.

-

The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

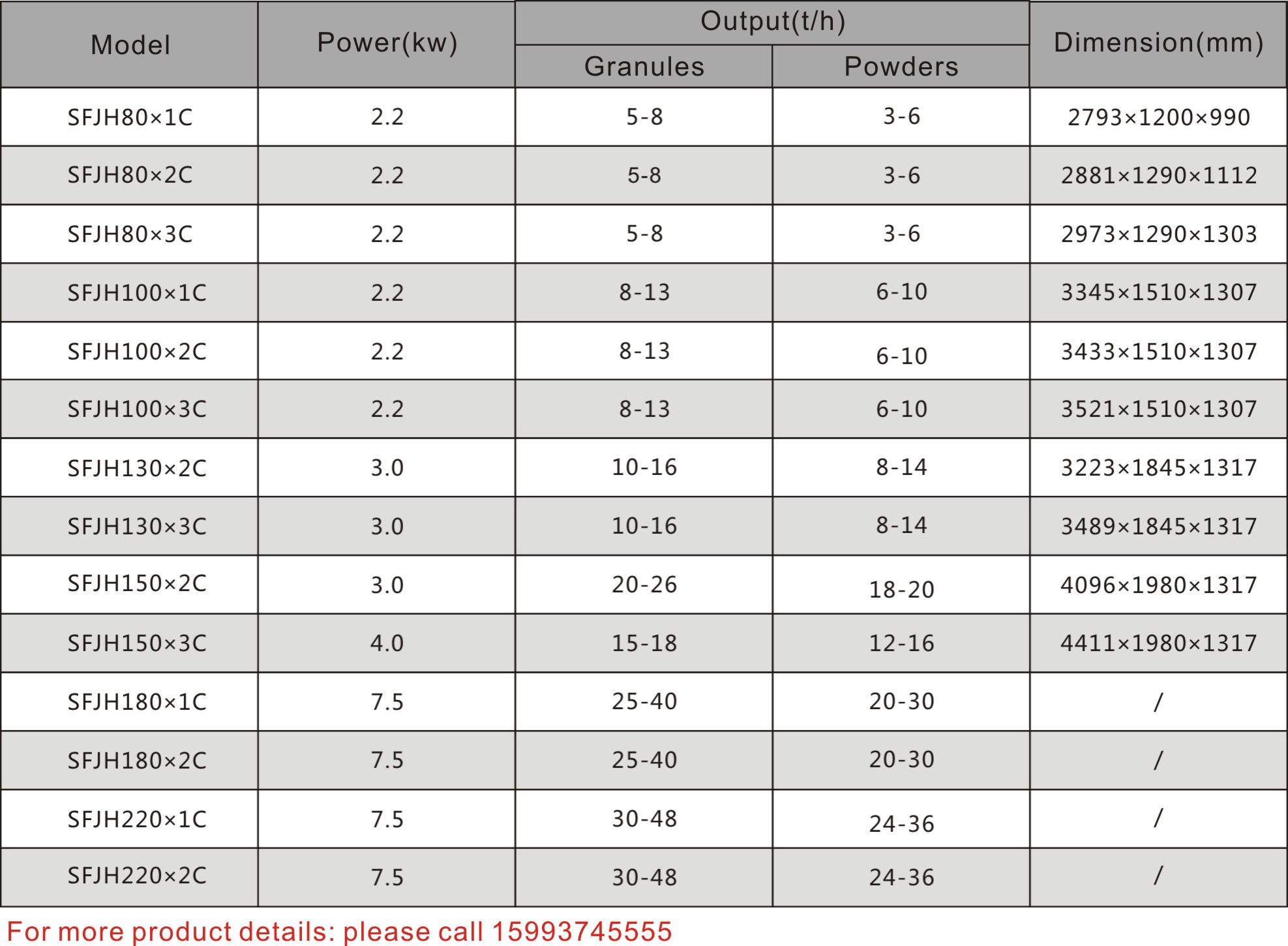

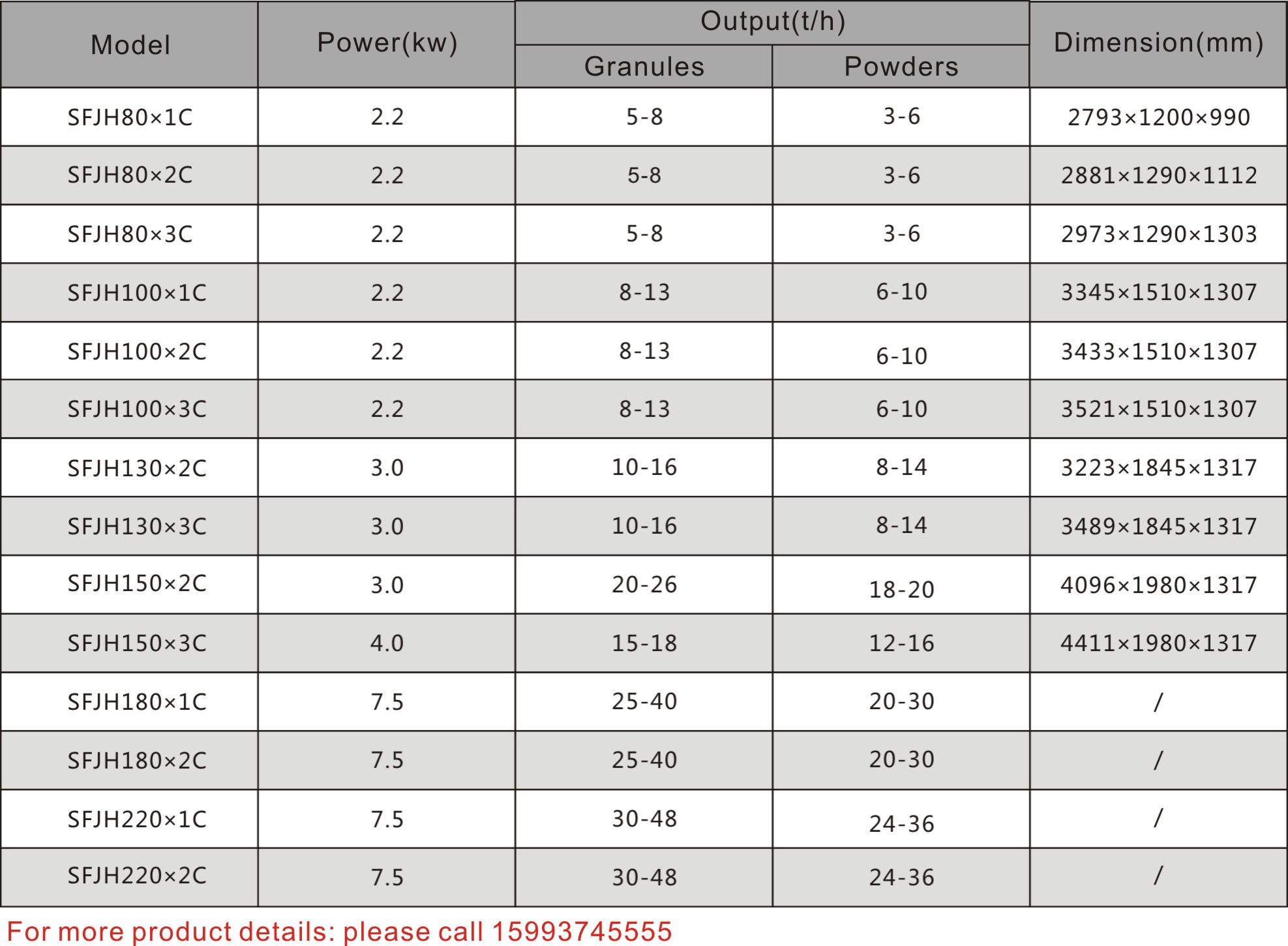

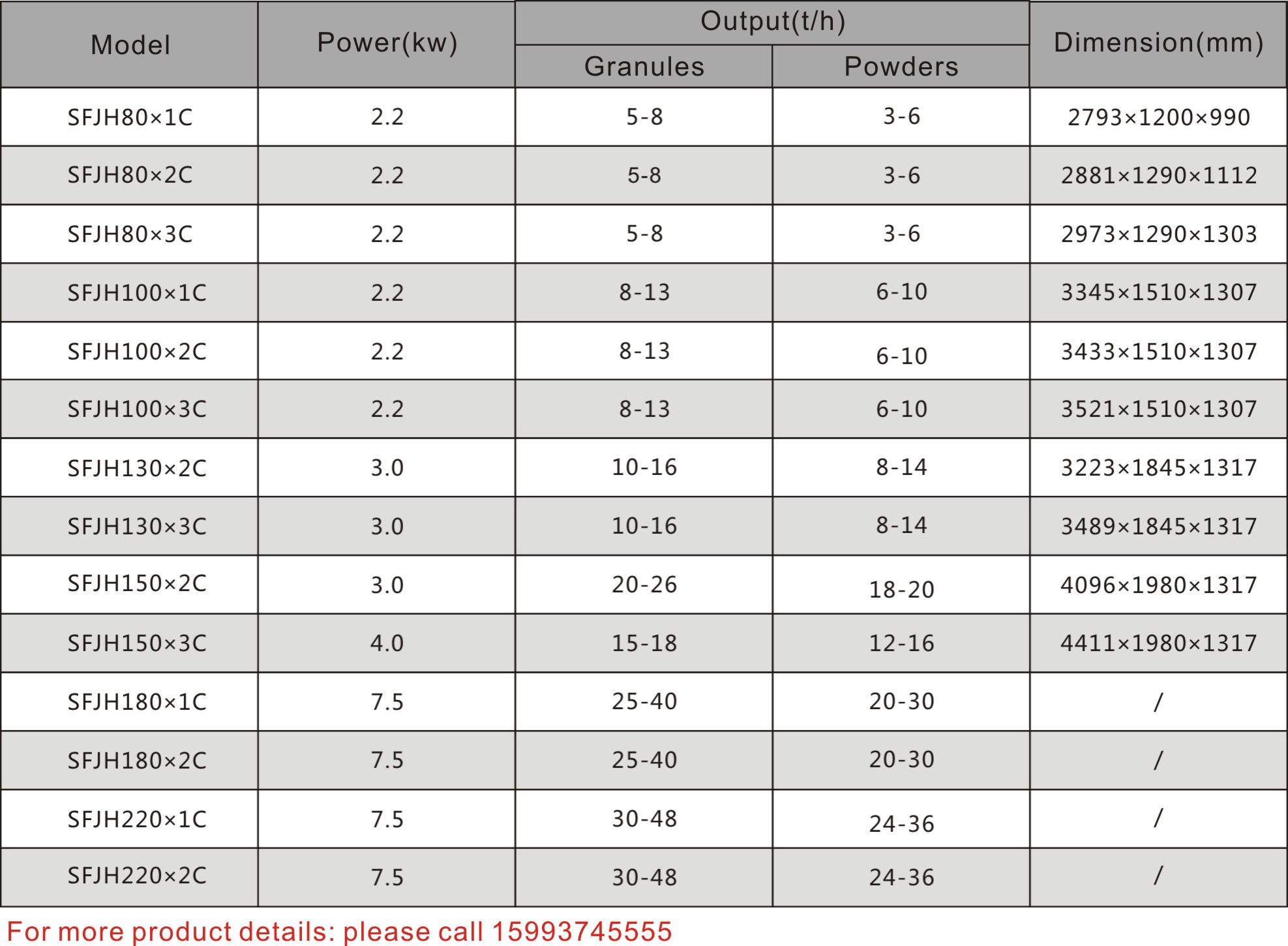

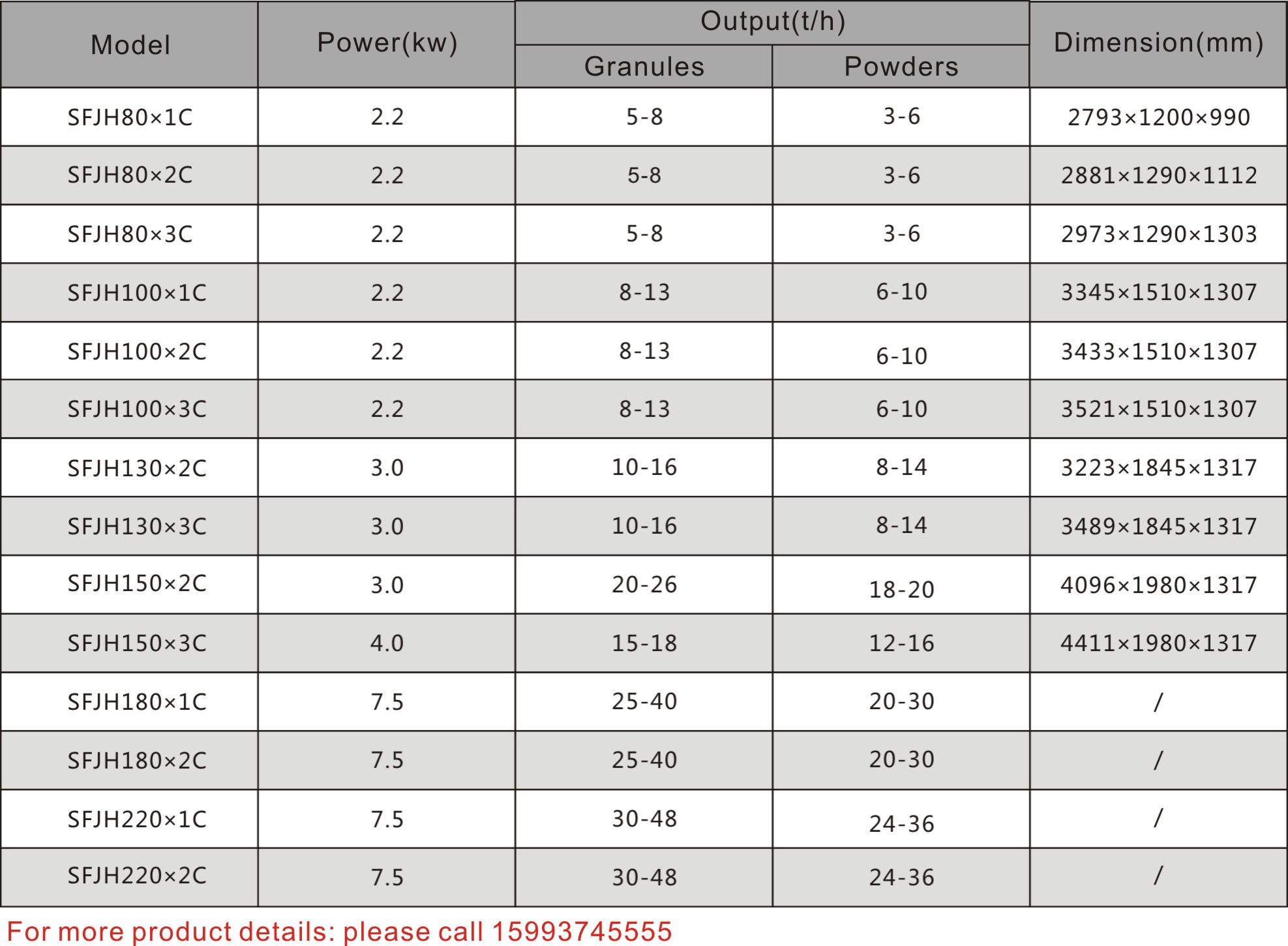

Technical parameters

-

- Commodity name: SFJH series rotary classifier

- Production capacity: 3-15t/h

- Applicable materials: Grain, food, chemical, sugar, mining, paper

- Applications: Geed mill, etc.

The power is transmitted from the motor to the drive device through the V-belt, and the drive device drives the screen body with a certain slope to move. The drive device is equipped with an eccentric device, so the movement track of the screen body from the feed end to the discharge end gradually changes from a horizontal circular motion to an elliptical motion, and becomes an approximate reciprocating linear motion. The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

1. It is suitable for the classification of granular materials and crushed materials and the secondary circulation crushing process.

2. Adopting the eccentric balance mechanism and elastic tail support mechanism driven by V-belt, the material rotates on the working surface of the horizontal rotating body, the screening efficiency is high, and the vibration is small.

3. The internal streamline design of the discharge port prevents material deposition and avoids cross-contamination.

4. The sieve pressing mechanism is firm and the sieve can be changed quickly.

5. Single-layer screen, two-layer screen and three-layer screen can be customized according to needs.

-

The material enters the sieve body from the feeding port, and is quickly and evenly distributed over the entire width of the sieve surface under the action of the circular motion of the feeding end of the sieve body, and automatic classification occurs. Therefore, the material with smaller particle size below the material layer is quickly sieved, while the material with larger particle size above moves along the slant of the sieve body to the lower end (discharge end).

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry