SHW single shaft double ring belt mixer

- Production capacity: 1-5t/h

- Applicable materials: Powder, etc.

- Applications: Feed mills, pastures, etc.

Classification:

Tel:

Introduction

-

The single-shaft ring-belt mixer of straw and animal husbandry machinery is a horizontal cylinder, and the inner rotor is composed of a ribbon-shaped spiral blade, a shaft, a ring and a support rod; the blades are divided into inner and outer circles, which are left-handed and right-handed respectively; When the rotor rotates, the left-handed blade pushes the material from one end to the other, and the right-handed blade moves the material in the opposite direction. Through this continuous turning and convection, the material is uniformly mixed. Both ends of the rotor are welded with scrapers near the inner wall of the machine and on the outer blade struts, so that the materials in the four corners of the machine can be fully stirred.

-

1. The straw grazing mechanical pellet machine can produce biomass pellets based on various raw materials such as wood chips, straw, chaff, etc.;

2. The use of various molding technologies such as cold pressing molding and extrusion molding, and the oil polishing and shaping process make the biomass particles beautiful in appearance and compact in structure.

3. The straw and animal husbandry mechanical pellet machine has high output, low energy consumption, low noise, low failure, strong fatigue resistance of the machine, continuous production, economical and durable;

4. The whole machine adopts special high-quality materials and advanced connecting shaft transmission device. The key components are made of high-quality alloy steel and wear-resistant materials, and heat-treated in a German vacuum furnace, which prolongs the service life by 5-7 times.

The biomass pellet machine is a pellet fuel molding machine that uses various branches, wood, wood chips, corn stalks, straw stalks, wood bran, wood powder, sawdust and other agricultural wastes as raw materials. For use in fireplaces, boilers, biomass power plants.

Advantage 1: It adopts high-precision involute cylindrical helical gears for direct transmission, and the transmission efficiency is as high as 98%.

Advantage 2: Normalizing heat treatment after water forging of the transmission gear tooth blank improves the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is as deep as 2.4mm to enhance the wear resistance and prolong the service life of the parts; hard tooth The surface is processed by the silent fine grinding and trimming process, which makes the operation quieter and more stable.

Advantage 3: The main shaft and the conjoined hollow shaft are made of alloy structural steel imported from Germany after water forging, rough turning, heat treatment, fine turning and fine grinding. The structure is reasonable and the hardness is uniform, which improves the fatigue resistance and wear resistance of the parts. Safe operation provides more reliable guarantee.

Advantage 4: The host box is made of high-quality steel, with uniform thickness and tight structure; it is carefully processed by a CNC machining center imported from Switzerland, and the machining accuracy is zero error. Provide stronger support for normal operation.

Advantage 5: The bearings and oil seals used in the transmission part are made of high-precision bearings imported from Japan and imported from the United States.

Advantage 6: The new generation of biomass pellet machine is developed and designed by Tongchuang designers, which is specially used for various biomass pelletizing. The company has its own production base. The ring die 560# biomass pellet machine has undergone hundreds of tests and demonstrations in the factory, and finally determined a more stable, more reliable, safer and more economical model. run.

-

All pressure is used for granulation, so the efficiency is high. The ring die granulator is further divided into the difference between the ring die granulator and the vertical ring die In the mold, the vertical ring mold is placed flat, with the mouth facing upward, and directly enters the pelletizing mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

Finished pellets

undefined

Features

-

- Commodity name: SHW single shaft double ring belt mixer

- Production capacity: 1-5t/h

- Applicable materials: Powder, etc.

- Applications: Feed mills, pastures, etc.

The single-shaft ring-belt mixer of straw and animal husbandry machinery is a horizontal cylinder, and the inner rotor is composed of a ribbon-shaped spiral blade, a shaft, a ring and a support rod; the blades are divided into inner and outer circles, which are left-handed and right-handed respectively; When the rotor rotates, the left-handed blade pushes the material from one end to the other, and the right-handed blade moves the material in the opposite direction. Through this continuous turning and convection, the material is uniformly mixed. Both ends of the rotor are welded with scrapers near the inner wall of the machine and on the outer blade struts, so that the materials in the four corners of the machine can be fully stirred.

-

1. The straw grazing mechanical pellet machine can produce biomass pellets based on various raw materials such as wood chips, straw, chaff, etc.;

2. The use of various molding technologies such as cold pressing molding and extrusion molding, and the oil polishing and shaping process make the biomass particles beautiful in appearance and compact in structure.

3. The straw and animal husbandry mechanical pellet machine has high output, low energy consumption, low noise, low failure, strong fatigue resistance of the machine, continuous production, economical and durable;

4. The whole machine adopts special high-quality materials and advanced connecting shaft transmission device. The key components are made of high-quality alloy steel and wear-resistant materials, and heat-treated in a German vacuum furnace, which prolongs the service life by 5-7 times.

The biomass pellet machine is a pellet fuel molding machine that uses various branches, wood, wood chips, corn stalks, straw stalks, wood bran, wood powder, sawdust and other agricultural wastes as raw materials. For use in fireplaces, boilers, biomass power plants.

Advantage 1: It adopts high-precision involute cylindrical helical gears for direct transmission, and the transmission efficiency is as high as 98%.

Advantage 2: Normalizing heat treatment after water forging of the transmission gear tooth blank improves the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is as deep as 2.4mm to enhance the wear resistance and prolong the service life of the parts; hard tooth The surface is processed by the silent fine grinding and trimming process, which makes the operation quieter and more stable.

Advantage 3: The main shaft and the conjoined hollow shaft are made of alloy structural steel imported from Germany after water forging, rough turning, heat treatment, fine turning and fine grinding. The structure is reasonable and the hardness is uniform, which improves the fatigue resistance and wear resistance of the parts. Safe operation provides more reliable guarantee.

Advantage 4: The host box is made of high-quality steel, with uniform thickness and tight structure; it is carefully processed by a CNC machining center imported from Switzerland, and the machining accuracy is zero error. Provide stronger support for normal operation.

Advantage 5: The bearings and oil seals used in the transmission part are made of high-precision bearings imported from Japan and imported from the United States.

Advantage 6: The new generation of biomass pellet machine is developed and designed by Tongchuang designers, which is specially used for various biomass pelletizing. The company has its own production base. The ring die 560# biomass pellet machine has undergone hundreds of tests and demonstrations in the factory, and finally determined a more stable, more reliable, safer and more economical model. run.

-

All pressure is used for granulation, so the efficiency is high. The ring die granulator is further divided into the difference between the ring die granulator and the vertical ring die In the mold, the vertical ring mold is placed flat, with the mouth facing upward, and directly enters the pelletizing mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

Working Principle

-

- Commodity name: SHW single shaft double ring belt mixer

- Production capacity: 1-5t/h

- Applicable materials: Powder, etc.

- Applications: Feed mills, pastures, etc.

The single-shaft ring-belt mixer of straw and animal husbandry machinery is a horizontal cylinder, and the inner rotor is composed of a ribbon-shaped spiral blade, a shaft, a ring and a support rod; the blades are divided into inner and outer circles, which are left-handed and right-handed respectively; When the rotor rotates, the left-handed blade pushes the material from one end to the other, and the right-handed blade moves the material in the opposite direction. Through this continuous turning and convection, the material is uniformly mixed. Both ends of the rotor are welded with scrapers near the inner wall of the machine and on the outer blade struts, so that the materials in the four corners of the machine can be fully stirred.

-

1. The straw grazing mechanical pellet machine can produce biomass pellets based on various raw materials such as wood chips, straw, chaff, etc.;

2. The use of various molding technologies such as cold pressing molding and extrusion molding, and the oil polishing and shaping process make the biomass particles beautiful in appearance and compact in structure.

3. The straw and animal husbandry mechanical pellet machine has high output, low energy consumption, low noise, low failure, strong fatigue resistance of the machine, continuous production, economical and durable;

4. The whole machine adopts special high-quality materials and advanced connecting shaft transmission device. The key components are made of high-quality alloy steel and wear-resistant materials, and heat-treated in a German vacuum furnace, which prolongs the service life by 5-7 times.

The biomass pellet machine is a pellet fuel molding machine that uses various branches, wood, wood chips, corn stalks, straw stalks, wood bran, wood powder, sawdust and other agricultural wastes as raw materials. For use in fireplaces, boilers, biomass power plants.

Advantage 1: It adopts high-precision involute cylindrical helical gears for direct transmission, and the transmission efficiency is as high as 98%.

Advantage 2: Normalizing heat treatment after water forging of the transmission gear tooth blank improves the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is as deep as 2.4mm to enhance the wear resistance and prolong the service life of the parts; hard tooth The surface is processed by the silent fine grinding and trimming process, which makes the operation quieter and more stable.

Advantage 3: The main shaft and the conjoined hollow shaft are made of alloy structural steel imported from Germany after water forging, rough turning, heat treatment, fine turning and fine grinding. The structure is reasonable and the hardness is uniform, which improves the fatigue resistance and wear resistance of the parts. Safe operation provides more reliable guarantee.

Advantage 4: The host box is made of high-quality steel, with uniform thickness and tight structure; it is carefully processed by a CNC machining center imported from Switzerland, and the machining accuracy is zero error. Provide stronger support for normal operation.

Advantage 5: The bearings and oil seals used in the transmission part are made of high-precision bearings imported from Japan and imported from the United States.

Advantage 6: The new generation of biomass pellet machine is developed and designed by Tongchuang designers, which is specially used for various biomass pelletizing. The company has its own production base. The ring die 560# biomass pellet machine has undergone hundreds of tests and demonstrations in the factory, and finally determined a more stable, more reliable, safer and more economical model. run.

-

All pressure is used for granulation, so the efficiency is high. The ring die granulator is further divided into the difference between the ring die granulator and the vertical ring die In the mold, the vertical ring mold is placed flat, with the mouth facing upward, and directly enters the pelletizing mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

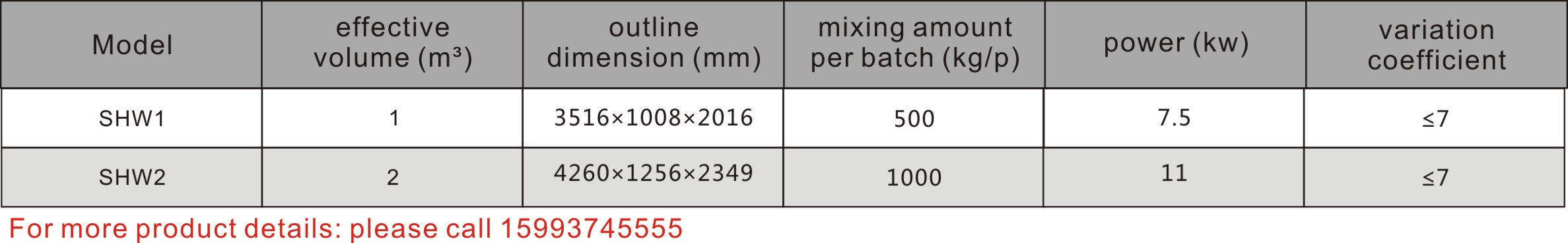

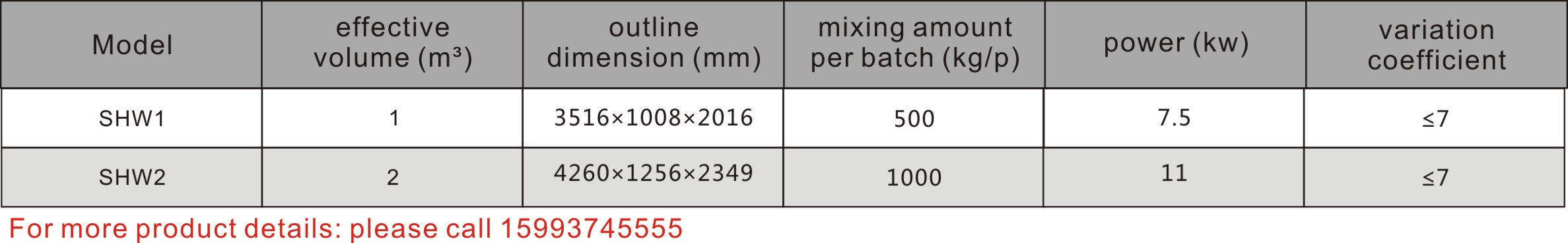

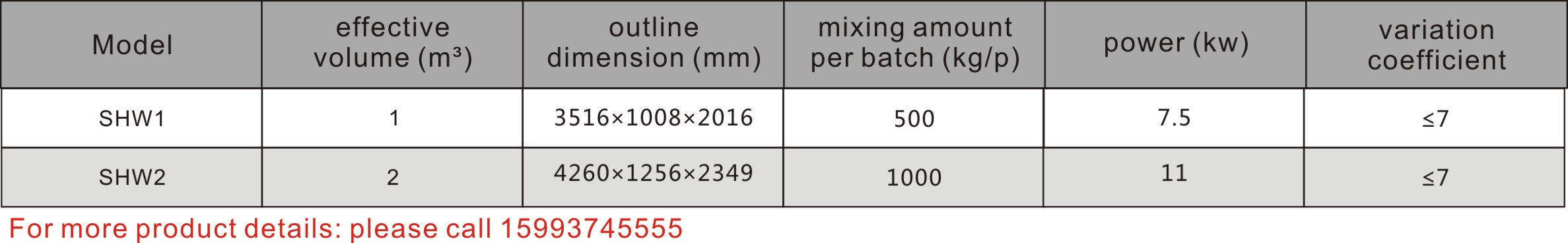

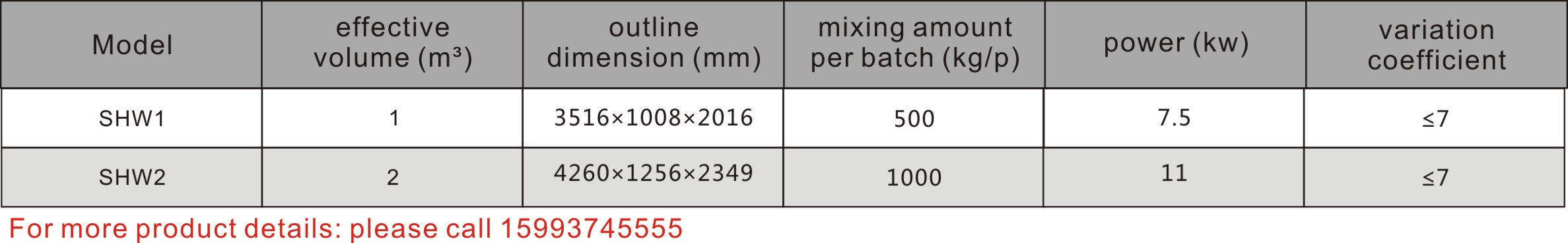

Technical parameters

-

- Commodity name: SHW single shaft double ring belt mixer

- Production capacity: 1-5t/h

- Applicable materials: Powder, etc.

- Applications: Feed mills, pastures, etc.

The single-shaft ring-belt mixer of straw and animal husbandry machinery is a horizontal cylinder, and the inner rotor is composed of a ribbon-shaped spiral blade, a shaft, a ring and a support rod; the blades are divided into inner and outer circles, which are left-handed and right-handed respectively; When the rotor rotates, the left-handed blade pushes the material from one end to the other, and the right-handed blade moves the material in the opposite direction. Through this continuous turning and convection, the material is uniformly mixed. Both ends of the rotor are welded with scrapers near the inner wall of the machine and on the outer blade struts, so that the materials in the four corners of the machine can be fully stirred.

-

1. The straw grazing mechanical pellet machine can produce biomass pellets based on various raw materials such as wood chips, straw, chaff, etc.;

2. The use of various molding technologies such as cold pressing molding and extrusion molding, and the oil polishing and shaping process make the biomass particles beautiful in appearance and compact in structure.

3. The straw and animal husbandry mechanical pellet machine has high output, low energy consumption, low noise, low failure, strong fatigue resistance of the machine, continuous production, economical and durable;

4. The whole machine adopts special high-quality materials and advanced connecting shaft transmission device. The key components are made of high-quality alloy steel and wear-resistant materials, and heat-treated in a German vacuum furnace, which prolongs the service life by 5-7 times.

The biomass pellet machine is a pellet fuel molding machine that uses various branches, wood, wood chips, corn stalks, straw stalks, wood bran, wood powder, sawdust and other agricultural wastes as raw materials. For use in fireplaces, boilers, biomass power plants.

Advantage 1: It adopts high-precision involute cylindrical helical gears for direct transmission, and the transmission efficiency is as high as 98%.

Advantage 2: Normalizing heat treatment after water forging of the transmission gear tooth blank improves the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is as deep as 2.4mm to enhance the wear resistance and prolong the service life of the parts; hard tooth The surface is processed by the silent fine grinding and trimming process, which makes the operation quieter and more stable.

Advantage 3: The main shaft and the conjoined hollow shaft are made of alloy structural steel imported from Germany after water forging, rough turning, heat treatment, fine turning and fine grinding. The structure is reasonable and the hardness is uniform, which improves the fatigue resistance and wear resistance of the parts. Safe operation provides more reliable guarantee.

Advantage 4: The host box is made of high-quality steel, with uniform thickness and tight structure; it is carefully processed by a CNC machining center imported from Switzerland, and the machining accuracy is zero error. Provide stronger support for normal operation.

Advantage 5: The bearings and oil seals used in the transmission part are made of high-precision bearings imported from Japan and imported from the United States.

Advantage 6: The new generation of biomass pellet machine is developed and designed by Tongchuang designers, which is specially used for various biomass pelletizing. The company has its own production base. The ring die 560# biomass pellet machine has undergone hundreds of tests and demonstrations in the factory, and finally determined a more stable, more reliable, safer and more economical model. run.

-

All pressure is used for granulation, so the efficiency is high. The ring die granulator is further divided into the difference between the ring die granulator and the vertical ring die In the mold, the vertical ring mold is placed flat, with the mouth facing upward, and directly enters the pelletizing mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry