SKLN series counter flow cooler

- Production capacity: 3-9m3/p

- Applicable materials: Pelletized feed, expansive feed, extruded feed, tablet feed, etc.

- Applications: Feed mills, pastures, etc.

Classification:

Tel:

Introduction

-

After the hot granular material enters the cooling bin through the rotary feeder, it gradually accumulates until it reaches a certain height. When the material touches the upper level device, the motor of the discharge transmission device starts to work. The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this time, the time relay starts to work, and by setting a certain delay discharge time, the automatic

Dynamic unloading.

-

1. Fully cooled to prolong the storage time of materials

◇The advanced countercurrent cooling principle is widely used in the cooling of various pellet feeds in the feed industry, such as the cooling treatment of pelletized feeds, expansive feeds, extruded feeds, and tablet feeds.

◇The cooling bin with an octagonal cross-section reduces the dead angle of cooling, and when the output is less than 6/h, it is conducive to the uniform cooling of the material.

2. Fence unloading mechanism, the unloading amount is even

◇Using the discharge fence type discharge mechanism with reciprocating linear motion, the discharge is smooth and the discharge amount is uniform.

◇Vertical overall layout, simple and beautiful appearance.

3. Humanized design, long service life

◇An inspection door is set on the front of the equipment, and observation windows are set on the side and top cover, which is convenient for observation and maintenance of the equipment.

◇The unloading mechanism is equipped with a decompression plate, which improves the working load of the unloading mechanism, reduces deformation and prolongs the service life of the components.

◇The transmission device adopts the geared motor to drive the eccentric shaft transmission, the transmission is stable and reliable, the noise is low, and the installation and maintenance are convenient.

-

The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this point, the time relay starts to work, by setting

A certain delay discharge time, automatic discharge.

-

Finished pellets

undefined

Features

-

- Commodity name: SKLN series counter flow cooler

- Production capacity: 3-9m3/p

- Applicable materials: Pelletized feed, expansive feed, extruded feed, tablet feed, etc.

- Applications: Feed mills, pastures, etc.

After the hot granular material enters the cooling bin through the rotary feeder, it gradually accumulates until it reaches a certain height. When the material touches the upper level device, the motor of the discharge transmission device starts to work. The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this time, the time relay starts to work, and by setting a certain delay discharge time, the automatic

Dynamic unloading.

-

1. Fully cooled to prolong the storage time of materials

◇The advanced countercurrent cooling principle is widely used in the cooling of various pellet feeds in the feed industry, such as the cooling treatment of pelletized feeds, expansive feeds, extruded feeds, and tablet feeds.

◇The cooling bin with an octagonal cross-section reduces the dead angle of cooling, and when the output is less than 6/h, it is conducive to the uniform cooling of the material.

2. Fence unloading mechanism, the unloading amount is even

◇Using the discharge fence type discharge mechanism with reciprocating linear motion, the discharge is smooth and the discharge amount is uniform.

◇Vertical overall layout, simple and beautiful appearance.

3. Humanized design, long service life

◇An inspection door is set on the front of the equipment, and observation windows are set on the side and top cover, which is convenient for observation and maintenance of the equipment.

◇The unloading mechanism is equipped with a decompression plate, which improves the working load of the unloading mechanism, reduces deformation and prolongs the service life of the components.

◇The transmission device adopts the geared motor to drive the eccentric shaft transmission, the transmission is stable and reliable, the noise is low, and the installation and maintenance are convenient.

-

The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this point, the time relay starts to work, by setting

A certain delay discharge time, automatic discharge.

-

Working Principle

-

- Commodity name: SKLN series counter flow cooler

- Production capacity: 3-9m3/p

- Applicable materials: Pelletized feed, expansive feed, extruded feed, tablet feed, etc.

- Applications: Feed mills, pastures, etc.

After the hot granular material enters the cooling bin through the rotary feeder, it gradually accumulates until it reaches a certain height. When the material touches the upper level device, the motor of the discharge transmission device starts to work. The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this time, the time relay starts to work, and by setting a certain delay discharge time, the automatic

Dynamic unloading.

-

1. Fully cooled to prolong the storage time of materials

◇The advanced countercurrent cooling principle is widely used in the cooling of various pellet feeds in the feed industry, such as the cooling treatment of pelletized feeds, expansive feeds, extruded feeds, and tablet feeds.

◇The cooling bin with an octagonal cross-section reduces the dead angle of cooling, and when the output is less than 6/h, it is conducive to the uniform cooling of the material.

2. Fence unloading mechanism, the unloading amount is even

◇Using the discharge fence type discharge mechanism with reciprocating linear motion, the discharge is smooth and the discharge amount is uniform.

◇Vertical overall layout, simple and beautiful appearance.

3. Humanized design, long service life

◇An inspection door is set on the front of the equipment, and observation windows are set on the side and top cover, which is convenient for observation and maintenance of the equipment.

◇The unloading mechanism is equipped with a decompression plate, which improves the working load of the unloading mechanism, reduces deformation and prolongs the service life of the components.

◇The transmission device adopts the geared motor to drive the eccentric shaft transmission, the transmission is stable and reliable, the noise is low, and the installation and maintenance are convenient.

-

The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this point, the time relay starts to work, by setting

A certain delay discharge time, automatic discharge.

-

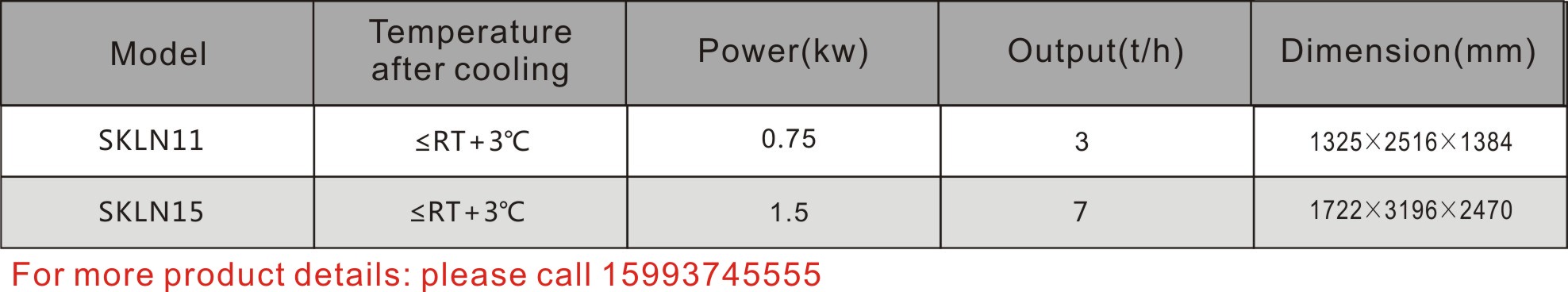

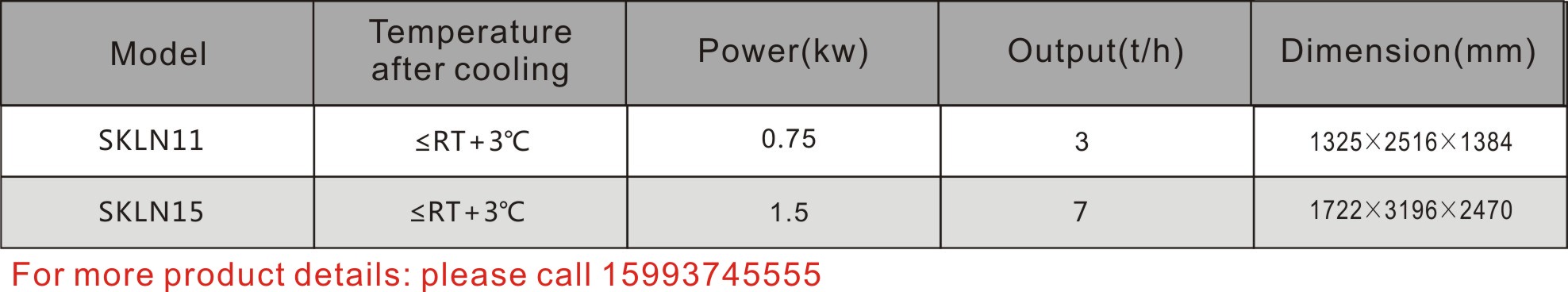

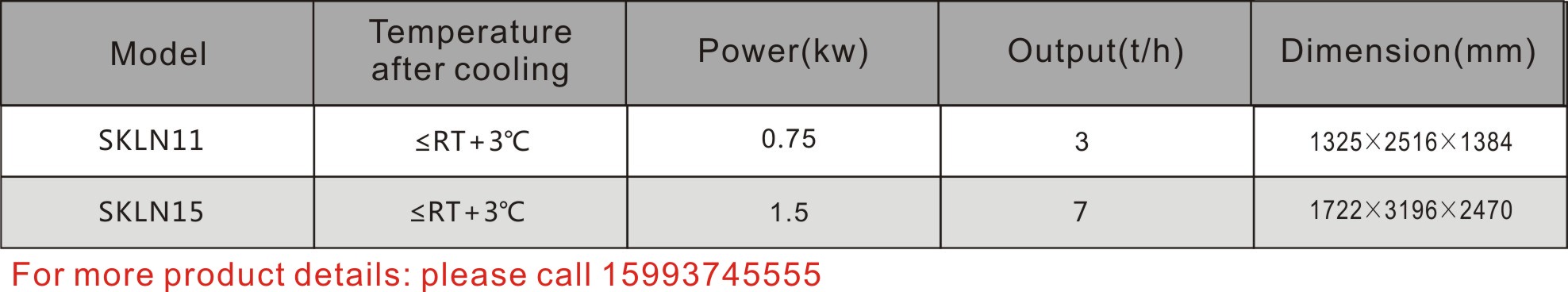

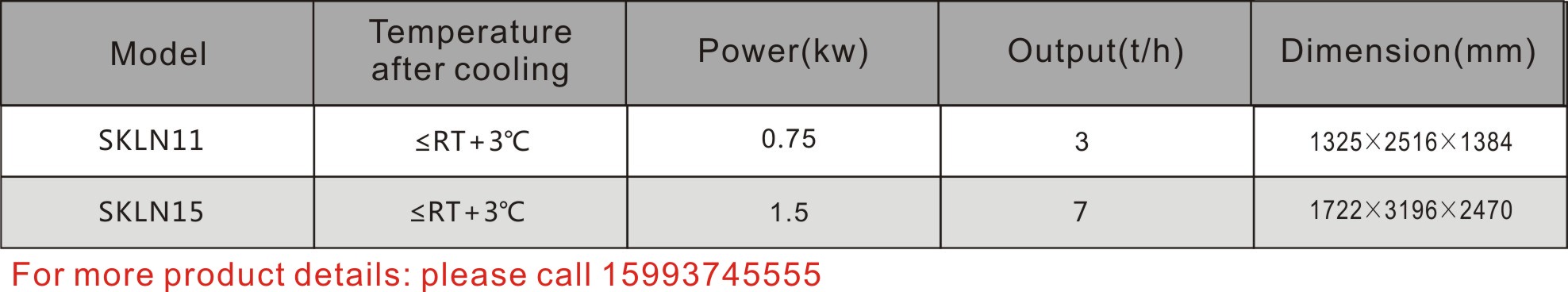

Technical parameters

-

- Commodity name: SKLN series counter flow cooler

- Production capacity: 3-9m3/p

- Applicable materials: Pelletized feed, expansive feed, extruded feed, tablet feed, etc.

- Applications: Feed mills, pastures, etc.

After the hot granular material enters the cooling bin through the rotary feeder, it gradually accumulates until it reaches a certain height. When the material touches the upper level device, the motor of the discharge transmission device starts to work. The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this time, the time relay starts to work, and by setting a certain delay discharge time, the automatic

Dynamic unloading.

-

1. Fully cooled to prolong the storage time of materials

◇The advanced countercurrent cooling principle is widely used in the cooling of various pellet feeds in the feed industry, such as the cooling treatment of pelletized feeds, expansive feeds, extruded feeds, and tablet feeds.

◇The cooling bin with an octagonal cross-section reduces the dead angle of cooling, and when the output is less than 6/h, it is conducive to the uniform cooling of the material.

2. Fence unloading mechanism, the unloading amount is even

◇Using the discharge fence type discharge mechanism with reciprocating linear motion, the discharge is smooth and the discharge amount is uniform.

◇Vertical overall layout, simple and beautiful appearance.

3. Humanized design, long service life

◇An inspection door is set on the front of the equipment, and observation windows are set on the side and top cover, which is convenient for observation and maintenance of the equipment.

◇The unloading mechanism is equipped with a decompression plate, which improves the working load of the unloading mechanism, reduces deformation and prolongs the service life of the components.

◇The transmission device adopts the geared motor to drive the eccentric shaft transmission, the transmission is stable and reliable, the noise is low, and the installation and maintenance are convenient.

-

The motor drives the discharge fence to reciprocate through the reducer and the eccentric mechanism to discharge the material. At this point, the time relay starts to work, by setting

A certain delay discharge time, automatic discharge.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry