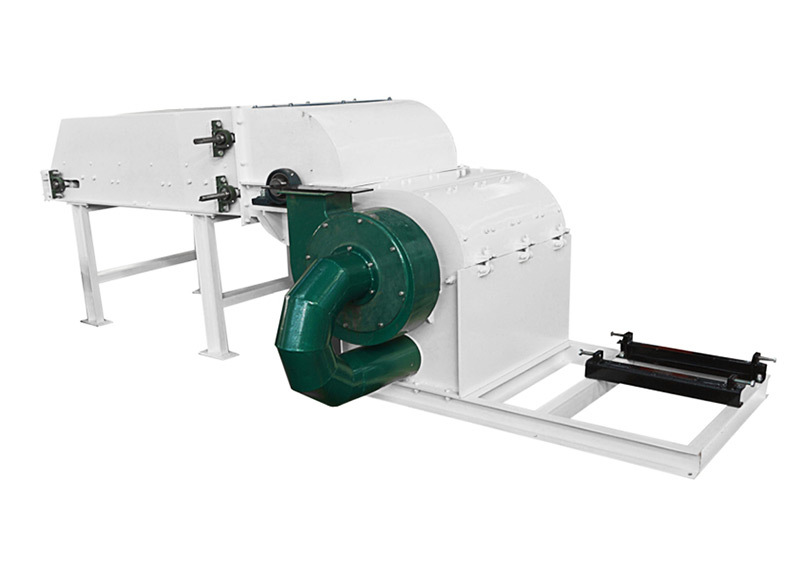

Kneading and crushing machine

- Production capacity: 1-5t/h

- Applicable materials: Straw, grass raw materials, etc.

- Applications: Pastures, feed mills, etc.

Classification:

Tel:

Introduction

-

Hammer mill is generally used for crushing straw materials, and its structure consists of three parts: feeding mechanism, crushing chamber (rotor, hammer, sieve, tooth plate), and discharge part (fan, collecting cylinder, dust bag). When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. , the material is subjected to strong friction. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to pass through the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.) The air in the mixed air stream is separated from the pulverization.

Straw pulverizers are roughly divided into three types: double-rotor pulverizers (radial feed), grass pulverizers (side feed), and wide-width pulverizers (side feed). The wet pulverizer consists of a feeding mechanism, a feeding mechanism, a cutting mechanism, and a shredder. The primary crushing chamber uses a cutter for cutting, and the secondary crushing chamber selects a multi-knife rotor F-type blade. When the material reaches the size of the sieve hole , Under the action of the negative pressure of the fan, the material is transported and collected by air. The fine can be adjusted to 60 mesh, and the coarse can be adjusted to 30 mm. The throughput is hammer mill

3-5 times.

The silk kneading and crushing integrated machine combines the functions of the silk kneading machine and the crusher. The function of the kneading board becomes the silk strip. Then it is transported to the pulverizer, and then it is pulverized under the blow of the hammer, and under the action of the fan, the material passes through the screen and enters the discharger and the air-closer. Collect finished powder. Different fineness of materials can be achieved by adjusting the screen.

Key words:- 一(yī)體機(jī)

- 粉碎機(jī)

- 稭稈

-

-

When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to be mixed by the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.). The air in the airflow is separated from the crushing.

-

Finished pellets

undefined

Features

-

- Commodity name: Kneading and crushing machine

- Production capacity: 1-5t/h

- Applicable materials: Straw, grass raw materials, etc.

- Applications: Pastures, feed mills, etc.

Hammer mill is generally used for crushing straw materials, and its structure consists of three parts: feeding mechanism, crushing chamber (rotor, hammer, sieve, tooth plate), and discharge part (fan, collecting cylinder, dust bag). When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. , the material is subjected to strong friction. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to pass through the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.) The air in the mixed air stream is separated from the pulverization.

Straw pulverizers are roughly divided into three types: double-rotor pulverizers (radial feed), grass pulverizers (side feed), and wide-width pulverizers (side feed). The wet pulverizer consists of a feeding mechanism, a feeding mechanism, a cutting mechanism, and a shredder. The primary crushing chamber uses a cutter for cutting, and the secondary crushing chamber selects a multi-knife rotor F-type blade. When the material reaches the size of the sieve hole , Under the action of the negative pressure of the fan, the material is transported and collected by air. The fine can be adjusted to 60 mesh, and the coarse can be adjusted to 30 mm. The throughput is hammer mill

3-5 times.

The silk kneading and crushing integrated machine combines the functions of the silk kneading machine and the crusher. The function of the kneading board becomes the silk strip. Then it is transported to the pulverizer, and then it is pulverized under the blow of the hammer, and under the action of the fan, the material passes through the screen and enters the discharger and the air-closer. Collect finished powder. Different fineness of materials can be achieved by adjusting the screen.

Key words:- 一(yī)體機(jī)

- 粉碎機(jī)

- 稭稈

-

-

When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to be mixed by the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.). The air in the airflow is separated from the crushing.

-

Working Principle

-

- Commodity name: Kneading and crushing machine

- Production capacity: 1-5t/h

- Applicable materials: Straw, grass raw materials, etc.

- Applications: Pastures, feed mills, etc.

Hammer mill is generally used for crushing straw materials, and its structure consists of three parts: feeding mechanism, crushing chamber (rotor, hammer, sieve, tooth plate), and discharge part (fan, collecting cylinder, dust bag). When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. , the material is subjected to strong friction. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to pass through the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.) The air in the mixed air stream is separated from the pulverization.

Straw pulverizers are roughly divided into three types: double-rotor pulverizers (radial feed), grass pulverizers (side feed), and wide-width pulverizers (side feed). The wet pulverizer consists of a feeding mechanism, a feeding mechanism, a cutting mechanism, and a shredder. The primary crushing chamber uses a cutter for cutting, and the secondary crushing chamber selects a multi-knife rotor F-type blade. When the material reaches the size of the sieve hole , Under the action of the negative pressure of the fan, the material is transported and collected by air. The fine can be adjusted to 60 mesh, and the coarse can be adjusted to 30 mm. The throughput is hammer mill

3-5 times.

The silk kneading and crushing integrated machine combines the functions of the silk kneading machine and the crusher. The function of the kneading board becomes the silk strip. Then it is transported to the pulverizer, and then it is pulverized under the blow of the hammer, and under the action of the fan, the material passes through the screen and enters the discharger and the air-closer. Collect finished powder. Different fineness of materials can be achieved by adjusting the screen.

Key words:- 一(yī)體機(jī)

- 粉碎機(jī)

- 稭稈

-

-

When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to be mixed by the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.). The air in the airflow is separated from the crushing.

-

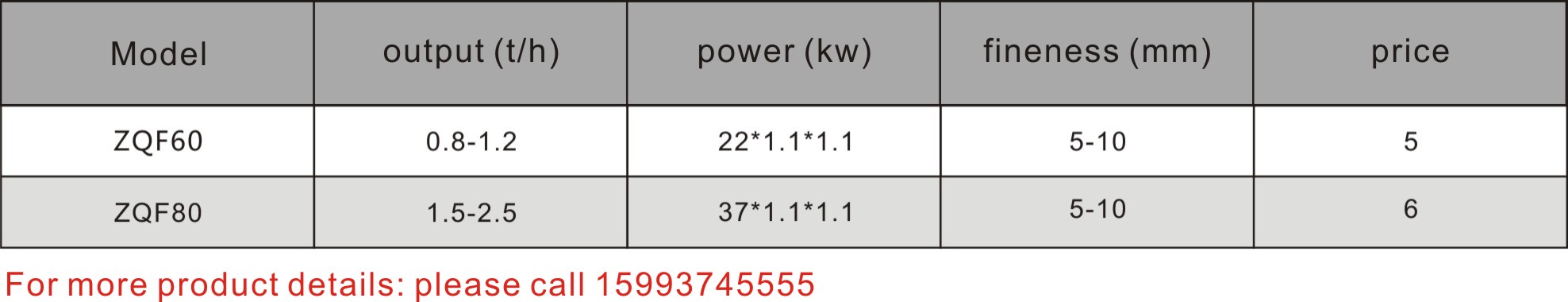

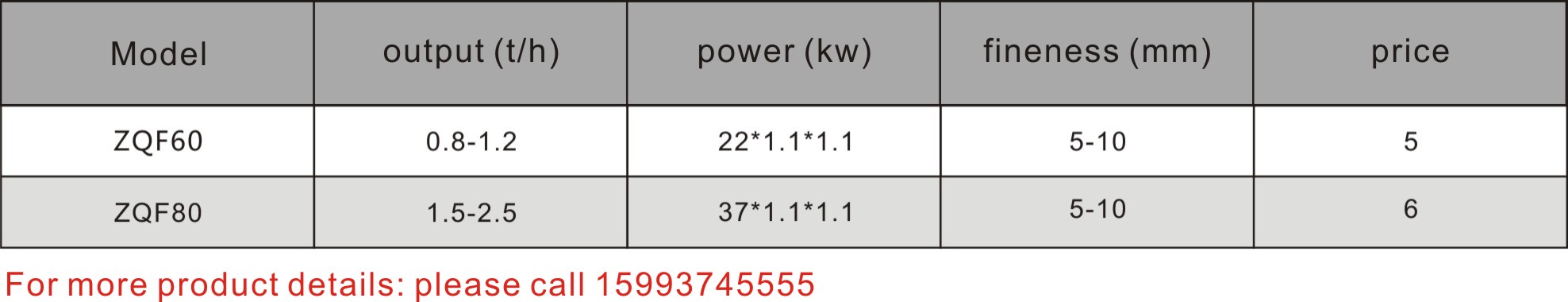

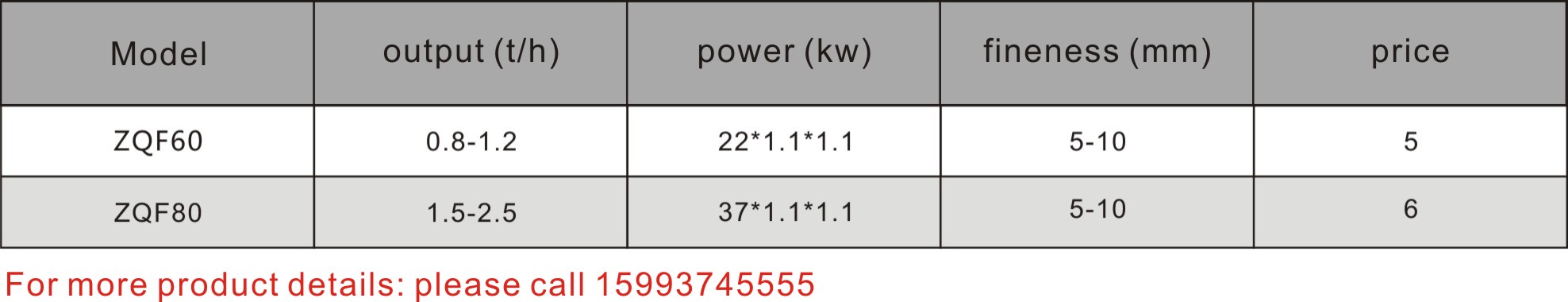

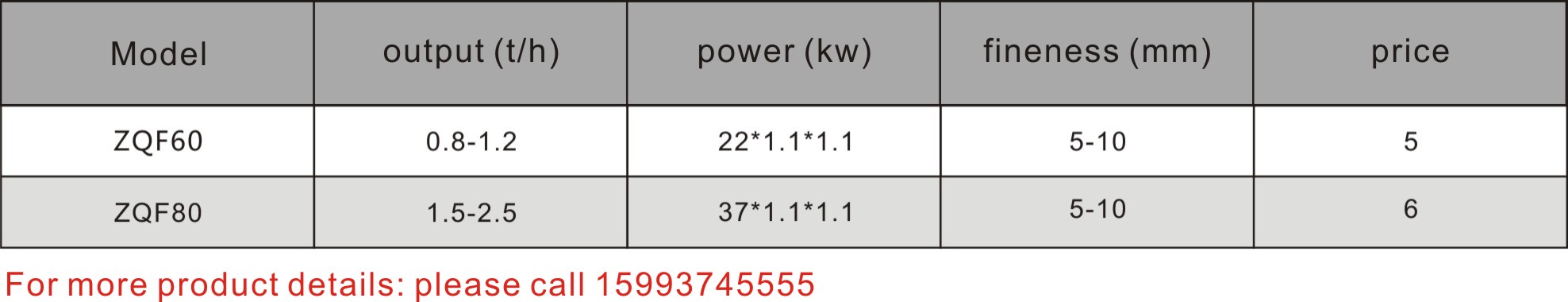

Technical parameters

-

- Commodity name: Kneading and crushing machine

- Production capacity: 1-5t/h

- Applicable materials: Straw, grass raw materials, etc.

- Applications: Pastures, feed mills, etc.

Hammer mill is generally used for crushing straw materials, and its structure consists of three parts: feeding mechanism, crushing chamber (rotor, hammer, sieve, tooth plate), and discharge part (fan, collecting cylinder, dust bag). When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. , the material is subjected to strong friction. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to pass through the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.) The air in the mixed air stream is separated from the pulverization.

Straw pulverizers are roughly divided into three types: double-rotor pulverizers (radial feed), grass pulverizers (side feed), and wide-width pulverizers (side feed). The wet pulverizer consists of a feeding mechanism, a feeding mechanism, a cutting mechanism, and a shredder. The primary crushing chamber uses a cutter for cutting, and the secondary crushing chamber selects a multi-knife rotor F-type blade. When the material reaches the size of the sieve hole , Under the action of the negative pressure of the fan, the material is transported and collected by air. The fine can be adjusted to 60 mesh, and the coarse can be adjusted to 30 mm. The throughput is hammer mill

3-5 times.

The silk kneading and crushing integrated machine combines the functions of the silk kneading machine and the crusher. The function of the kneading board becomes the silk strip. Then it is transported to the pulverizer, and then it is pulverized under the blow of the hammer, and under the action of the fan, the material passes through the screen and enters the discharger and the air-closer. Collect finished powder. Different fineness of materials can be achieved by adjusting the screen.

Key words:- 一(yī)體機(jī)

- 粉碎機(jī)

- 稭稈

-

-

When working, the material enters the crushing chamber from the feeding mechanism, and flies to the toothed plate under the blow of the high-speed rotating hammer. After colliding with the toothed plate, it bounces back and is hit by the hammer again. Under the action of repeated blows, collisions and frictions, the raw materials are gradually pulverized. After the fan pulls the pulverized material out of the sieve hole, it still needs to be mixed by the powder collecting device (such as collecting cylinder, dust collecting cloth bag, etc.). The air in the airflow is separated from the crushing.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry