Precision feeding management system and centralized control system

- Applicable materials: Cattle, sheep, rabbits, etc.

- Applications: Pasture, etc.

Classification:

Tel:

Introduction

-

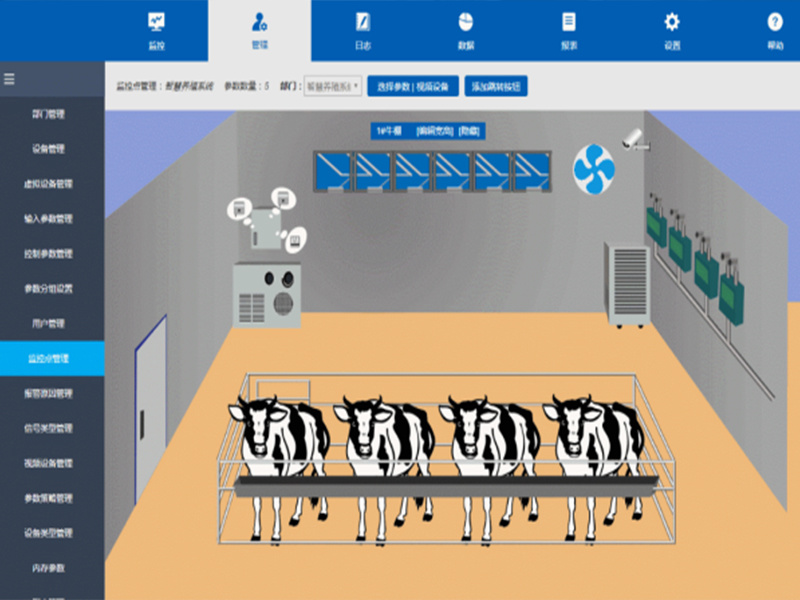

(1) Centralized control system:

The daily production of 200 tons of total mixed ration is operated on the touch screen and computer in the central control room, and the site is unattended. Automatic control is generally composed of analog screen control cabinet, strong electric cabinet, field control equipment and computer intelligent control terminal.

Analog screen control cabinet (CCP): photo of analog screen, photo of electric cabinet, analog screen control, circuit breaker, contactor, products of Schneider; inverter, product of Danfoss; relay, product of Weidmüller; sensor use Keli or Tuoliduo; computer monitors use Philips; PLC uses Siemens or Mitsubishi, and the main electrical components use Schneider products, grid bridges,

(2) Intelligent feeding management system:

1 Overview:

The system can also develop a communication protocol port according to the internal management system of the enterprise, connect with the enterprise management system, realize the functions of data access, query, printing, data sharing of production tasks in advance, hierarchical management and different permission setting functions. The system adopts the precise feeding management system and centralized control system of DIGI-STAR in the United States. This system is currently widely used in the fixed feeding stations of large-scale pastures in China; the software and hardware of this system are of reliable quality, high quality and stable performance, which are the current A first-line brand selected by large domestic farms.

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes the seamless connection of internal information of the ranch. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

2. Design scheme of centralized control and feeding management system in detail:

As the core of the entire feeding station system, the centralized control system performs centralized data processing and task assignment. The roughage addition prompt, the automatic control system for the concentrated feed, and the precise feeding management system are integrated by the industrial control system and operated on the same control platform. The control flow is as follows:

(1) Production of TMR rations: TMR Tracker precision feeding software is responsible for the production of formulas, and sends formulas from different sections to different control systems through the network or wirelessly, and collects and generates information about self-made rations. Various data reports, including daily feed production accuracy, feed spreader operation accuracy, feed intake, dry matter intake, raw material consumption and other reports, and can be output according to requirements.

(2) Concentrate production and addition: The concentrate PLC control system collects the concentrate formula data of the precision feeding system TMR Tracker feeding management software, and realizes direct data transmission. It is transported to the corresponding position and automatically controls the addition process of the concentrate.

(3) Addition of roughage conveyor: the roughage formula data of the precision feeding system TMR Tracker feeding management software, the feeding system processes the data of each roughage formula and displays it on the large screen of each mixer truck, prompting the forklift driver Add to the corresponding TMR preparation machine according to the order of addition and weight.

-

-

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes seamless information within the ranch.docking. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

-

For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Precision feeding management system and centralized control system

- Applicable materials: Cattle, sheep, rabbits, etc.

- Applications: Pasture, etc.

(1) Centralized control system:

The daily production of 200 tons of total mixed ration is operated on the touch screen and computer in the central control room, and the site is unattended. Automatic control is generally composed of analog screen control cabinet, strong electric cabinet, field control equipment and computer intelligent control terminal.

Analog screen control cabinet (CCP): photo of analog screen, photo of electric cabinet, analog screen control, circuit breaker, contactor, products of Schneider; inverter, product of Danfoss; relay, product of Weidmüller; sensor use Keli or Tuoliduo; computer monitors use Philips; PLC uses Siemens or Mitsubishi, and the main electrical components use Schneider products, grid bridges,

(2) Intelligent feeding management system:

1 Overview:

The system can also develop a communication protocol port according to the internal management system of the enterprise, connect with the enterprise management system, realize the functions of data access, query, printing, data sharing of production tasks in advance, hierarchical management and different permission setting functions. The system adopts the precise feeding management system and centralized control system of DIGI-STAR in the United States. This system is currently widely used in the fixed feeding stations of large-scale pastures in China; the software and hardware of this system are of reliable quality, high quality and stable performance, which are the current A first-line brand selected by large domestic farms.

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes the seamless connection of internal information of the ranch. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

2. Design scheme of centralized control and feeding management system in detail:

As the core of the entire feeding station system, the centralized control system performs centralized data processing and task assignment. The roughage addition prompt, the automatic control system for the concentrated feed, and the precise feeding management system are integrated by the industrial control system and operated on the same control platform. The control flow is as follows:

(1) Production of TMR rations: TMR Tracker precision feeding software is responsible for the production of formulas, and sends formulas from different sections to different control systems through the network or wirelessly, and collects and generates information about self-made rations. Various data reports, including daily feed production accuracy, feed spreader operation accuracy, feed intake, dry matter intake, raw material consumption and other reports, and can be output according to requirements.

(2) Concentrate production and addition: The concentrate PLC control system collects the concentrate formula data of the precision feeding system TMR Tracker feeding management software, and realizes direct data transmission. It is transported to the corresponding position and automatically controls the addition process of the concentrate.

(3) Addition of roughage conveyor: the roughage formula data of the precision feeding system TMR Tracker feeding management software, the feeding system processes the data of each roughage formula and displays it on the large screen of each mixer truck, prompting the forklift driver Add to the corresponding TMR preparation machine according to the order of addition and weight.

-

-

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes seamless information within the ranch.docking. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

-

For more product details: please call 15993745555

Working Principle

-

- Commodity name: Precision feeding management system and centralized control system

- Applicable materials: Cattle, sheep, rabbits, etc.

- Applications: Pasture, etc.

(1) Centralized control system:

The daily production of 200 tons of total mixed ration is operated on the touch screen and computer in the central control room, and the site is unattended. Automatic control is generally composed of analog screen control cabinet, strong electric cabinet, field control equipment and computer intelligent control terminal.

Analog screen control cabinet (CCP): photo of analog screen, photo of electric cabinet, analog screen control, circuit breaker, contactor, products of Schneider; inverter, product of Danfoss; relay, product of Weidmüller; sensor use Keli or Tuoliduo; computer monitors use Philips; PLC uses Siemens or Mitsubishi, and the main electrical components use Schneider products, grid bridges,

(2) Intelligent feeding management system:

1 Overview:

The system can also develop a communication protocol port according to the internal management system of the enterprise, connect with the enterprise management system, realize the functions of data access, query, printing, data sharing of production tasks in advance, hierarchical management and different permission setting functions. The system adopts the precise feeding management system and centralized control system of DIGI-STAR in the United States. This system is currently widely used in the fixed feeding stations of large-scale pastures in China; the software and hardware of this system are of reliable quality, high quality and stable performance, which are the current A first-line brand selected by large domestic farms.

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes the seamless connection of internal information of the ranch. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

2. Design scheme of centralized control and feeding management system in detail:

As the core of the entire feeding station system, the centralized control system performs centralized data processing and task assignment. The roughage addition prompt, the automatic control system for the concentrated feed, and the precise feeding management system are integrated by the industrial control system and operated on the same control platform. The control flow is as follows:

(1) Production of TMR rations: TMR Tracker precision feeding software is responsible for the production of formulas, and sends formulas from different sections to different control systems through the network or wirelessly, and collects and generates information about self-made rations. Various data reports, including daily feed production accuracy, feed spreader operation accuracy, feed intake, dry matter intake, raw material consumption and other reports, and can be output according to requirements.

(2) Concentrate production and addition: The concentrate PLC control system collects the concentrate formula data of the precision feeding system TMR Tracker feeding management software, and realizes direct data transmission. It is transported to the corresponding position and automatically controls the addition process of the concentrate.

(3) Addition of roughage conveyor: the roughage formula data of the precision feeding system TMR Tracker feeding management software, the feeding system processes the data of each roughage formula and displays it on the large screen of each mixer truck, prompting the forklift driver Add to the corresponding TMR preparation machine according to the order of addition and weight.

-

-

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes seamless information within the ranch.docking. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

-

For more product details: please call 15993745555

Technical parameters

-

- Commodity name: Precision feeding management system and centralized control system

- Applicable materials: Cattle, sheep, rabbits, etc.

- Applications: Pasture, etc.

(1) Centralized control system:

The daily production of 200 tons of total mixed ration is operated on the touch screen and computer in the central control room, and the site is unattended. Automatic control is generally composed of analog screen control cabinet, strong electric cabinet, field control equipment and computer intelligent control terminal.

Analog screen control cabinet (CCP): photo of analog screen, photo of electric cabinet, analog screen control, circuit breaker, contactor, products of Schneider; inverter, product of Danfoss; relay, product of Weidmüller; sensor use Keli or Tuoliduo; computer monitors use Philips; PLC uses Siemens or Mitsubishi, and the main electrical components use Schneider products, grid bridges,

(2) Intelligent feeding management system:

1 Overview:

The system can also develop a communication protocol port according to the internal management system of the enterprise, connect with the enterprise management system, realize the functions of data access, query, printing, data sharing of production tasks in advance, hierarchical management and different permission setting functions. The system adopts the precise feeding management system and centralized control system of DIGI-STAR in the United States. This system is currently widely used in the fixed feeding stations of large-scale pastures in China; the software and hardware of this system are of reliable quality, high quality and stable performance, which are the current A first-line brand selected by large domestic farms.

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes the seamless connection of internal information of the ranch. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

2. Design scheme of centralized control and feeding management system in detail:

As the core of the entire feeding station system, the centralized control system performs centralized data processing and task assignment. The roughage addition prompt, the automatic control system for the concentrated feed, and the precise feeding management system are integrated by the industrial control system and operated on the same control platform. The control flow is as follows:

(1) Production of TMR rations: TMR Tracker precision feeding software is responsible for the production of formulas, and sends formulas from different sections to different control systems through the network or wirelessly, and collects and generates information about self-made rations. Various data reports, including daily feed production accuracy, feed spreader operation accuracy, feed intake, dry matter intake, raw material consumption and other reports, and can be output according to requirements.

(2) Concentrate production and addition: The concentrate PLC control system collects the concentrate formula data of the precision feeding system TMR Tracker feeding management software, and realizes direct data transmission. It is transported to the corresponding position and automatically controls the addition process of the concentrate.

(3) Addition of roughage conveyor: the roughage formula data of the precision feeding system TMR Tracker feeding management software, the feeding system processes the data of each roughage formula and displays it on the large screen of each mixer truck, prompting the forklift driver Add to the corresponding TMR preparation machine according to the order of addition and weight.

-

-

This scheme adopts a functional modular design scheme, which is an intelligent control system based on PLC and SCADS (Superviory Control And Data Acquisition/Data Acquisition and Monitoring), and realizes seamless information within the ranch.docking. The functional modules are divided into: TMR Tracker precise feeding software module, which realizes feeding formula preparation, feeding and receiving data sending and receiving, and report processing; The feeding and roughage processing module of the system can realize the precise addition of various roughages according to the requirements of the formula; the data transmission module can realize the automatic data transmission and processing of the ration production system and the concentrate system, and perform data docking with third-party software and other functions.

-

For more product details: please call 15993745555

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry