Screw feeder

- Production capacity: 3-30t/h

- Applicable materials: Powder, granular and small block materials

Classification:

Tel:

Introduction

-

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end. Small volume, high speed, uniform feeding, good precision and low residue. The inlet blades are arranged with equal diameter and variable distance to ensure the overall discharge of materials in the warehouse. Optional anti-blocking material alarm,speed alarm.

-

1. Small size, high speed, uniform feeding, good precision and low residue.

2. The inlet blades are arranged with equal diameter and variable distance to ensure the overall discharge of materials in the warehouse.

3. Optional anti-blocking material alarm and speed measurement alarm.

-

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end.

-

Finished pellets

undefined

Features

-

- Commodity name: Screw feeder

- Production capacity: 3-30t/h

- Applicable materials: Powder, granular and small block materials

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end. Small volume, high speed, uniform feeding, good precision and low residue. The inlet blades are arranged with equal diameter and variable distance to ensure the overall discharge of materials in the warehouse. Optional anti-blocking material alarm,speed alarm.

-

1. Small size, high speed, uniform feeding, good precision and low residue.

3. Optional anti-blocking material alarm and speed measurement alarm.

-

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end.

-

Working Principle

-

- Commodity name: Screw feeder

- Production capacity: 3-30t/h

- Applicable materials: Powder, granular and small block materials

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end. Small volume, high speed, uniform feeding, good precision and low residue. The inlet blades are arranged with equal diameter and variable distance to ensure the overall discharge of materials in the warehouse. Optional anti-blocking material alarm,speed alarm.

-

1. Small size, high speed, uniform feeding, good precision and low residue.

2. The inlet blades are arranged with equal diameter and variable distance to ensure the overall discharge of materials in the warehouse.

3. Optional anti-blocking material alarm and speed measurement alarm.

-

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end.

-

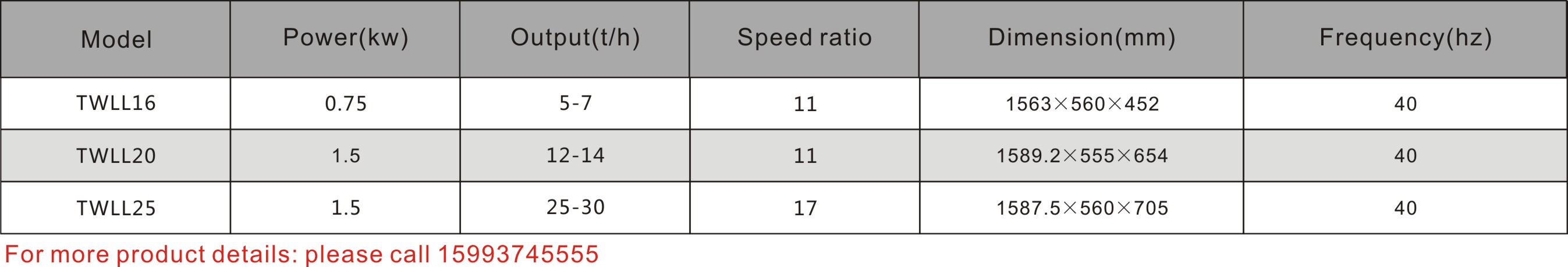

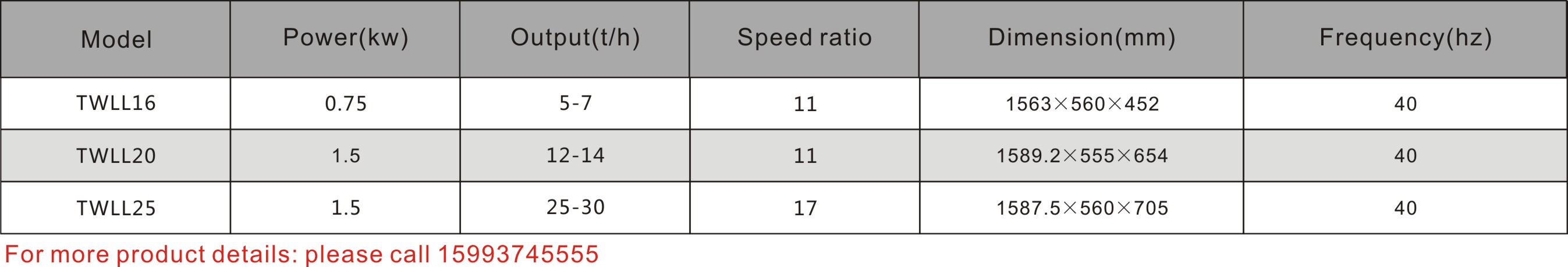

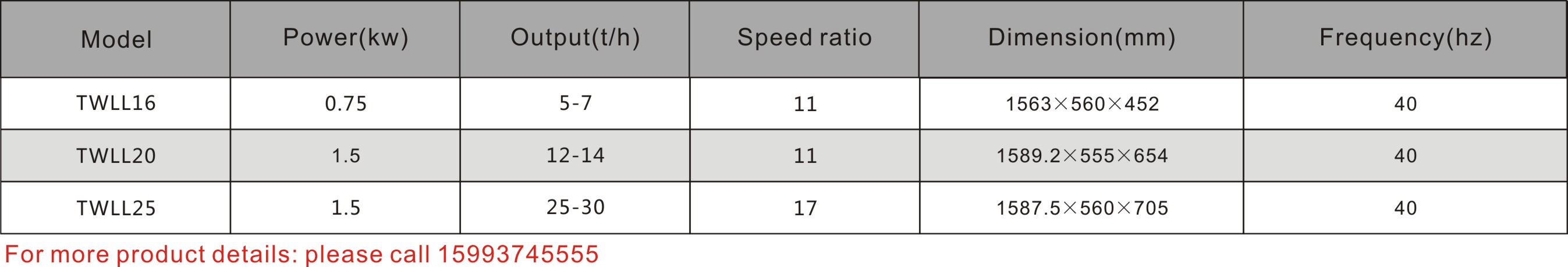

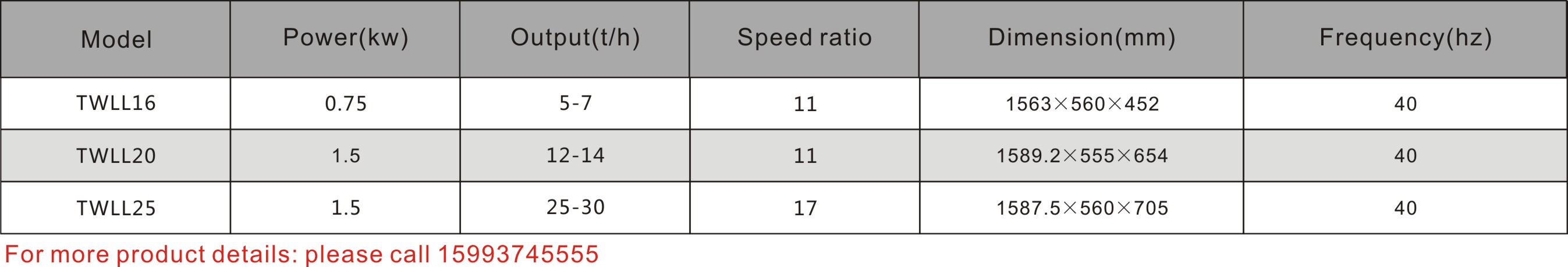

Technical parameters

-

- Commodity name: Screw feeder

- Production capacity: 3-30t/h

- Applicable materials: Powder, granular and small block materials

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end. Small volume, high speed, uniform feeding, good precision and low residue. The inlet blades are arranged with equal diameter and variable distance to ensure the overall discharge of materials in the warehouse. Optional anti-blocking material alarm,speed alarm.

-

1. Small size, high speed, uniform feeding, good precision and low residue.

2. The inlet blades are arranged with equal diameter and variable distance to ensure the overall discharge of materials in the warehouse.

3. Optional anti-blocking material alarm and speed measurement alarm.

-

When working, the material enters the conveying trough from the feeding port of the feeder or conveyor, and generates a thrust to the material through the rotation of the screw blade, and pushes the material from the feeding port to the discharging end.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry