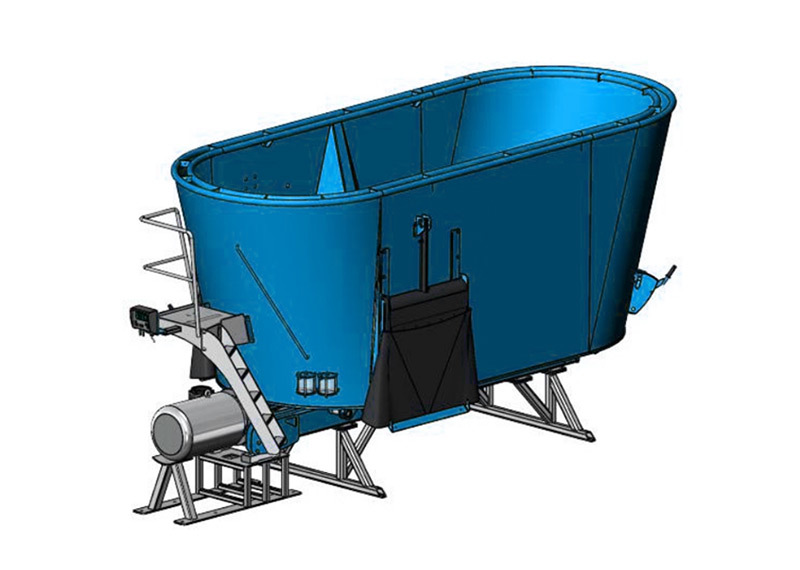

TMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Forage, concentrate, etc.

- Applications: Small livestock farms, cattle farms, sheep farms

Classification:

Tel:

Introduction

-

This TMR machine can be used for mixing and stirring all kinds of forage and all kinds of concentrates measured in proportion. Used in small livestock farms, cattle farms, sheep farms. It can also be used to prepare compound feed in cattle and sheep feed processing plants.

-

The vertical full-mixing ration mixer has a spiral auger that is divided into upper and lower spirals. During mixing and mixing, the materials are simultaneously rotated and stirred from both ends of the box to the middle of the mixer. The process is equipped with a moving blade, which works with the fixed teeth on the center line of the mixer for cutting work, and cuts and stirs all kinds of fibrous raw material straws that pass through, so as to obtain the effect of crushing and mixing the whole diet.

The hydraulic discharging mechanism is composed of a material gate, a hydraulic mechanism, a pin, a limit bolt and a travel switch. The discharge door is installed on the hydraulic cylinder, and the linkage shaft and the driven rocker of the linkage mechanism are connected together through a pin shaft. The hydraulic cylinder reciprocates, thereby driving the discharge door to open or close.

-

A. The raw materials of each component to be mixed and stirred are respectively put into the TMR machine by a belt conveyor or a forklift.

B. When each raw material is put in, the weighing system records the weight of the various raw materials put in separately. The weighing system adopts the accumulation method, and can prepare and mix different full-ration cattle and sheep feeds according to the formula.

C. The amount of mixing and stirring in each batch does not exceed the rated volume of the TMR machine.

D. The mixing time of each batch is 15-20 minutes.

E. The mixed finished product is sent to the specified position through the discharge door and belt conveyor.

-

For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: TMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Forage, concentrate, etc.

- Applications: Small livestock farms, cattle farms, sheep farms

This TMR machine can be used for mixing and stirring all kinds of forage and all kinds of concentrates measured in proportion. Used in small livestock farms, cattle farms, sheep farms. It can also be used to prepare compound feed in cattle and sheep feed processing plants.

-

The vertical full-mixing ration mixer has a spiral auger that is divided into upper and lower spirals. During mixing and mixing, the materials are simultaneously rotated and stirred from both ends of the box to the middle of the mixer. The process is equipped with a moving blade, which works with the fixed teeth on the center line of the mixer for cutting work, and cuts and stirs all kinds of fibrous raw material straws that pass through, so as to obtain the effect of crushing and mixing the whole diet.

The hydraulic discharging mechanism is composed of a material gate, a hydraulic mechanism, a pin, a limit bolt and a travel switch. The discharge door is installed on the hydraulic cylinder, and the linkage shaft and the driven rocker of the linkage mechanism are connected together through a pin shaft. The hydraulic cylinder reciprocates, thereby driving the discharge door to open or close.

-

A. The raw materials of each component to be mixed and stirred are respectively put into the TMR machine by a belt conveyor or a forklift.

B. When each raw material is put in, the weighing system records the weight of the various raw materials put in separately. The weighing system adopts the accumulation method, and can prepare and mix different full-ration cattle and sheep feeds according to the formula.

C. The amount of mixing and stirring in each batch does not exceed the rated volume of the TMR machine.

D. The mixing time of each batch is 15-20 minutes.

E. The mixed finished product is sent to the specified position through the discharge door and belt conveyor.

-

For more product details: please call 15993745555

Working Principle

-

- Commodity name: TMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Forage, concentrate, etc.

- Applications: Small livestock farms, cattle farms, sheep farms

This TMR machine can be used for mixing and stirring all kinds of forage and all kinds of concentrates measured in proportion. Used in small livestock farms, cattle farms, sheep farms. It can also be used to prepare compound feed in cattle and sheep feed processing plants.

-

The vertical full-mixing ration mixer has a spiral auger that is divided into upper and lower spirals. During mixing and mixing, the materials are simultaneously rotated and stirred from both ends of the box to the middle of the mixer. The process is equipped with a moving blade, which works with the fixed teeth on the center line of the mixer for cutting work, and cuts and stirs all kinds of fibrous raw material straws that pass through, so as to obtain the effect of crushing and mixing the whole diet.

The hydraulic discharging mechanism is composed of a material gate, a hydraulic mechanism, a pin, a limit bolt and a travel switch. The discharge door is installed on the hydraulic cylinder, and the linkage shaft and the driven rocker of the linkage mechanism are connected together through a pin shaft. The hydraulic cylinder reciprocates, thereby driving the discharge door to open or close.

-

A. The raw materials of each component to be mixed and stirred are respectively put into the TMR machine by a belt conveyor or a forklift.

B. When each raw material is put in, the weighing system records the weight of the various raw materials put in separately. The weighing system adopts the accumulation method, and can prepare and mix different full-ration cattle and sheep feeds according to the formula.

C. The amount of mixing and stirring in each batch does not exceed the rated volume of the TMR machine.

D. The mixing time of each batch is 15-20 minutes.

E. The mixed finished product is sent to the specified position through the discharge door and belt conveyor.

-

For more product details: please call 15993745555

Technical parameters

-

- Commodity name: TMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Forage, concentrate, etc.

- Applications: Small livestock farms, cattle farms, sheep farms

This TMR machine can be used for mixing and stirring all kinds of forage and all kinds of concentrates measured in proportion. Used in small livestock farms, cattle farms, sheep farms. It can also be used to prepare compound feed in cattle and sheep feed processing plants.

-

The vertical full-mixing ration mixer has a spiral auger that is divided into upper and lower spirals. During mixing and mixing, the materials are simultaneously rotated and stirred from both ends of the box to the middle of the mixer. The process is equipped with a moving blade, which works with the fixed teeth on the center line of the mixer for cutting work, and cuts and stirs all kinds of fibrous raw material straws that pass through, so as to obtain the effect of crushing and mixing the whole diet.

The hydraulic discharging mechanism is composed of a material gate, a hydraulic mechanism, a pin, a limit bolt and a travel switch. The discharge door is installed on the hydraulic cylinder, and the linkage shaft and the driven rocker of the linkage mechanism are connected together through a pin shaft. The hydraulic cylinder reciprocates, thereby driving the discharge door to open or close.

-

A. The raw materials of each component to be mixed and stirred are respectively put into the TMR machine by a belt conveyor or a forklift.

B. When each raw material is put in, the weighing system records the weight of the various raw materials put in separately. The weighing system adopts the accumulation method, and can prepare and mix different full-ration cattle and sheep feeds according to the formula.

C. The amount of mixing and stirring in each batch does not exceed the rated volume of the TMR machine.

D. The mixing time of each batch is 15-20 minutes.

E. The mixed finished product is sent to the specified position through the discharge door and belt conveyor.

-

For more product details: please call 15993745555

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry