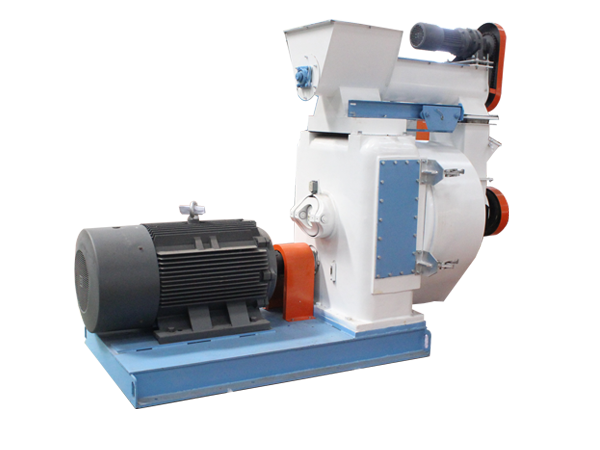

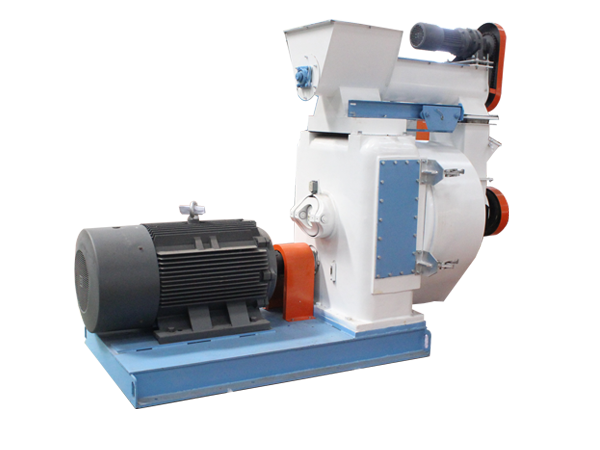

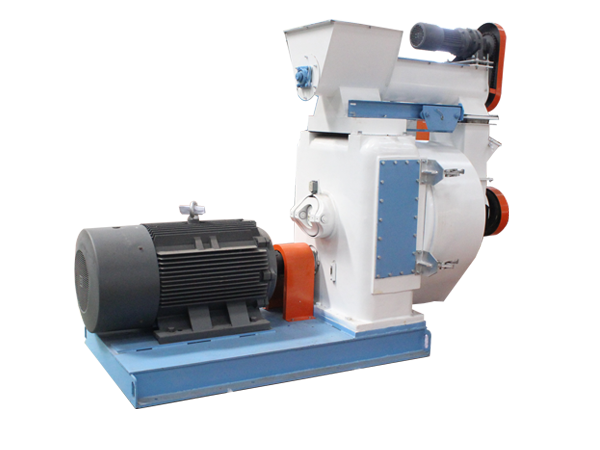

508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, coconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Classification:

Tel:

Introduction

-

Granulator is also called granulator, granulator, etc. There are two types of flat-mode pellet machines and ring-type pellet machines. The ring-molded pellet machines are divided into gear-driven pellet machines (CPM) and belt-driven pellet machines (UMT) from the transmission structure.

1. The main components of the flat die granulator are a flat round steel die and a set (2-4) of freely rotating pressing rollers with grooves. The raw material falls into the roller gap from top to bottom, and is rotated by the roller

Press into the die hole, extrude a long cylinder from below the die hole, and cut it into granules by a cutter. There are three transmission modes: drive roller, drive flat die and double drive. The characteristics of the flat die granulator are the

The structure is simple, the manufacture is relatively easy, and the cost is low, and it is suitable for pressing fibrous raw materials. However, the linear speed (circumferential speed) of the inner and outer diameters of the flat die is not equal during granulation, and it depends on the size of the raw material on the die.

Different centrifugal forces make the load on the working surface uneven. Therefore, the diameter of the flat die should not be too large, otherwise it will affect the uniformity of the finished product.

2. Ring die granulator and its working principle The ring die is a porous cylindrical cylinder, which is rotated by transmission. There are 2-4 free-rotating or driven auto-rotating rollers with grooves in the cylinder. The raw material enters the mold, that is, the rotating pressure roller is pressed into the workshop, embedded in the mold hole, extruded from the outer wall of the ring, and cut into cylindrical particles by the cutter

The main feature of the ring die granulator is that the linear speeds of the ring die and the pressing roller are equal everywhere. No extra friction,

All the pressure is used for granulation, so the efficiency is high. The ring die pellet machine is further divided into the difference between the ring die pellet machine and the vertical ring die

Down, and then turn 90 degrees to enter the granulation mold through forced feeding. The vertical ring die is placed in the flat mold, with the mouth upward, and directly enters the granulation mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

1. It has the unattainable performance of traditional double belt drive and gear drive granulator;

2. Forged one-piece main shaft, the support rod of the pressing roller is cancelled, and the main shaft is optimized, which greatly increases the rigidity of the main shaft and the supporting rigidity of the pressing roller, and the pressing chamber can withstand super large

Torque, always ensure the axial parallelism of the pressure roller and the ring die, the equipment is aging, and the output is not reduced; the output is increased by 10-12% year-on-year, and the number of equipment maintenance is reduced;

3. Automatic refueling when the machine is turned on, the refueling time and refueling amount can be arbitrarily set by the user according to the oil and material conditions, so as to avoid major damage to the machine due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency discharge door to avoid burning out the motor or causing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemens motor, Schneider Electric, on-site touch screen operation cabinet.

-

The working principle of the HKJ series biomass granulator of straw animal husbandry machinery is similar to that of the SZLH series animal feed granulator. The action of the scraper is used to feed the two pressing zones in the ring die evenly into the wedge-shaped space formed by the two pressing rollers and the ring die. Extruded into the die hole of the ring die and formed in the die hole. Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into particles of the required length by the cutter, and then enters the next process.

-

Finished pellets

undefined

Features

-

- Commodity name: 508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, coconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, granulator, etc. There are two types of flat-mode pellet machines and ring-type pellet machines. The ring-molded pellet machines are divided into gear-driven pellet machines (CPM) and belt-driven pellet machines (UMT) from the transmission structure.

1. The main components of the flat die granulator are a flat round steel die and a set (2-4) of freely rotating pressing rollers with grooves. The raw material falls into the roller gap from top to bottom, and is rotated by the roller

Press into the die hole, extrude a long cylinder from below the die hole, and cut it into granules by a cutter. There are three transmission modes: drive roller, drive flat die and double drive. The characteristics of the flat die granulator are the

The structure is simple, the manufacture is relatively easy, and the cost is low, and it is suitable for pressing fibrous raw materials. However, the linear speed (circumferential speed) of the inner and outer diameters of the flat die is not equal during granulation, and it depends on the size of the raw material on the die.

Different centrifugal forces make the load on the working surface uneven. Therefore, the diameter of the flat die should not be too large, otherwise it will affect the uniformity of the finished product.

2. Ring die granulator and its working principle The ring die is a porous cylindrical cylinder, which is rotated by transmission. There are 2-4 free-rotating or driven auto-rotating rollers with grooves in the cylinder. The raw material enters the mold, that is, the rotating pressure roller is pressed into the workshop, embedded in the mold hole, extruded from the outer wall of the ring, and cut into cylindrical particles by the cutter

The main feature of the ring die granulator is that the linear speeds of the ring die and the pressing roller are equal everywhere. No extra friction,

All the pressure is used for granulation, so the efficiency is high. The ring die pellet machine is further divided into the difference between the ring die pellet machine and the vertical ring die

Down, and then turn 90 degrees to enter the granulation mold through forced feeding. The vertical ring die is placed in the flat mold, with the mouth upward, and directly enters the granulation mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

1. It has the unattainable performance of traditional double belt drive and gear drive granulator;

2. Forged one-piece main shaft, the support rod of the pressing roller is cancelled, and the main shaft is optimized, which greatly increases the rigidity of the main shaft and the supporting rigidity of the pressing roller, and the pressing chamber can withstand super large

Torque, always ensure the axial parallelism of the pressure roller and the ring die, the equipment is aging, and the output is not reduced; the output is increased by 10-12% year-on-year, and the number of equipment maintenance is reduced;

3. Automatic refueling when the machine is turned on, the refueling time and refueling amount can be arbitrarily set by the user according to the oil and material conditions, so as to avoid major damage to the machine due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency discharge door to avoid burning out the motor or causing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemens motor, Schneider Electric, on-site touch screen operation cabinet.

-

The working principle of the HKJ series biomass granulator of straw animal husbandry machinery is similar to that of the SZLH series animal feed granulator. The action of the scraper is used to feed the two pressing zones in the ring die evenly into the wedge-shaped space formed by the two pressing rollers and the ring die. Extruded into the die hole of the ring die and formed in the die hole. Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into particles of the required length by the cutter, and then enters the next process.

-

Working Principle

-

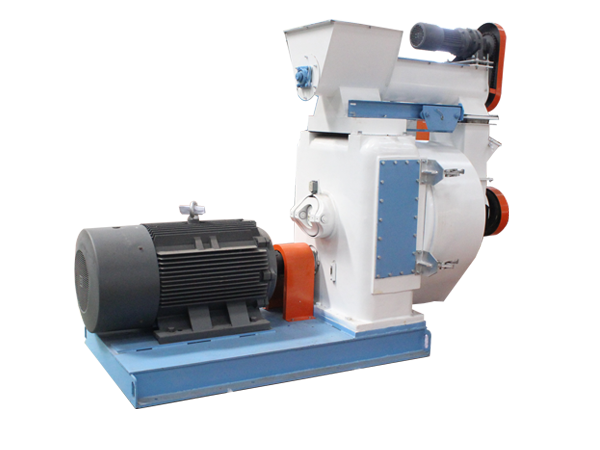

- Commodity name: 508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, coconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, granulator, etc. There are two types of flat-mode pellet machines and ring-type pellet machines. The ring-molded pellet machines are divided into gear-driven pellet machines (CPM) and belt-driven pellet machines (UMT) from the transmission structure.

1. The main components of the flat die granulator are a flat round steel die and a set (2-4) of freely rotating pressing rollers with grooves. The raw material falls into the roller gap from top to bottom, and is rotated by the roller

Press into the die hole, extrude a long cylinder from below the die hole, and cut it into granules by a cutter. There are three transmission modes: drive roller, drive flat die and double drive. The characteristics of the flat die granulator are the

The structure is simple, the manufacture is relatively easy, and the cost is low, and it is suitable for pressing fibrous raw materials. However, the linear speed (circumferential speed) of the inner and outer diameters of the flat die is not equal during granulation, and it depends on the size of the raw material on the die.

Different centrifugal forces make the load on the working surface uneven. Therefore, the diameter of the flat die should not be too large, otherwise it will affect the uniformity of the finished product.

2. Ring die granulator and its working principle The ring die is a porous cylindrical cylinder, which is rotated by transmission. There are 2-4 free-rotating or driven auto-rotating rollers with grooves in the cylinder. The raw material enters the mold, that is, the rotating pressure roller is pressed into the workshop, embedded in the mold hole, extruded from the outer wall of the ring, and cut into cylindrical particles by the cutter

The main feature of the ring die granulator is that the linear speeds of the ring die and the pressing roller are equal everywhere. No extra friction,

All the pressure is used for granulation, so the efficiency is high. The ring die pellet machine is further divided into the difference between the ring die pellet machine and the vertical ring die

Down, and then turn 90 degrees to enter the granulation mold through forced feeding. The vertical ring die is placed in the flat mold, with the mouth upward, and directly enters the granulation mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

1. It has the unattainable performance of traditional double belt drive and gear drive granulator;

2. Forged one-piece main shaft, the support rod of the pressing roller is cancelled, and the main shaft is optimized, which greatly increases the rigidity of the main shaft and the supporting rigidity of the pressing roller, and the pressing chamber can withstand super large

Torque, always ensure the axial parallelism of the pressure roller and the ring die, the equipment is aging, and the output is not reduced; the output is increased by 10-12% year-on-year, and the number of equipment maintenance is reduced;

3. Automatic refueling when the machine is turned on, the refueling time and refueling amount can be arbitrarily set by the user according to the oil and material conditions, so as to avoid major damage to the machine due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency discharge door to avoid burning out the motor or causing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemens motor, Schneider Electric, on-site touch screen operation cabinet.

-

The working principle of the HKJ series biomass granulator of straw animal husbandry machinery is similar to that of the SZLH series animal feed granulator. The action of the scraper is used to feed the two pressing zones in the ring die evenly into the wedge-shaped space formed by the two pressing rollers and the ring die. Extruded into the die hole of the ring die and formed in the die hole. Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into particles of the required length by the cutter, and then enters the next process.

-

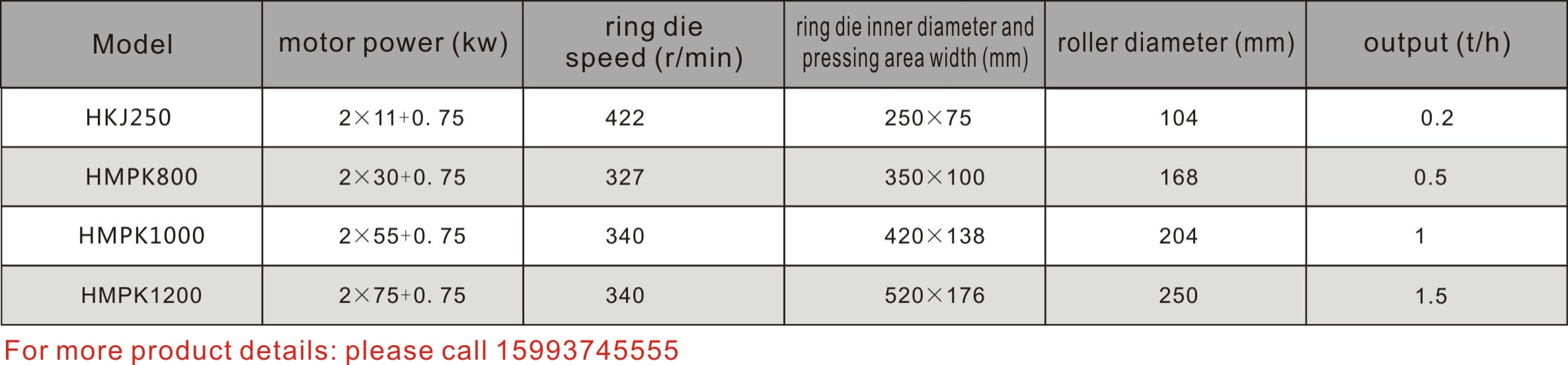

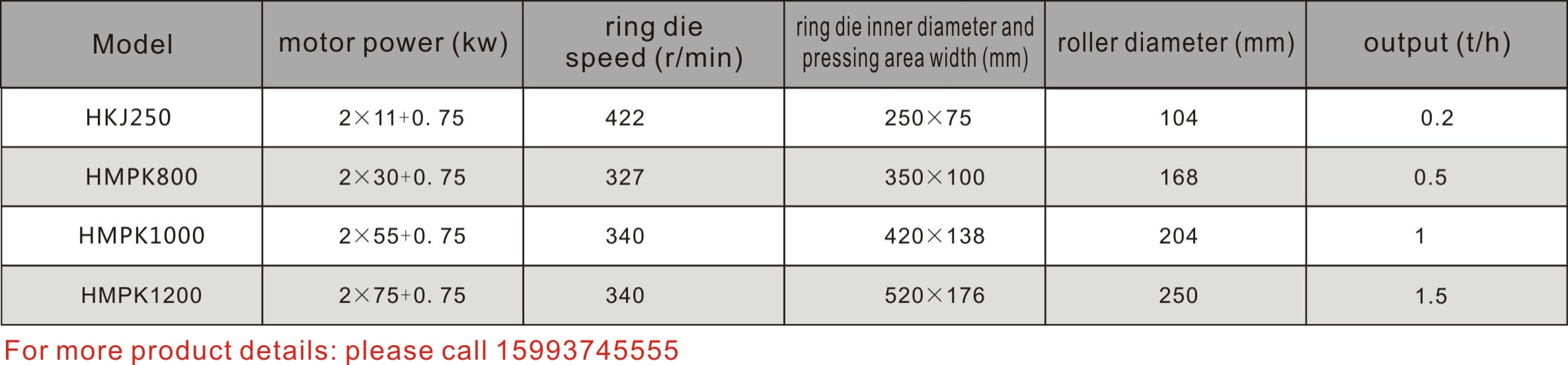

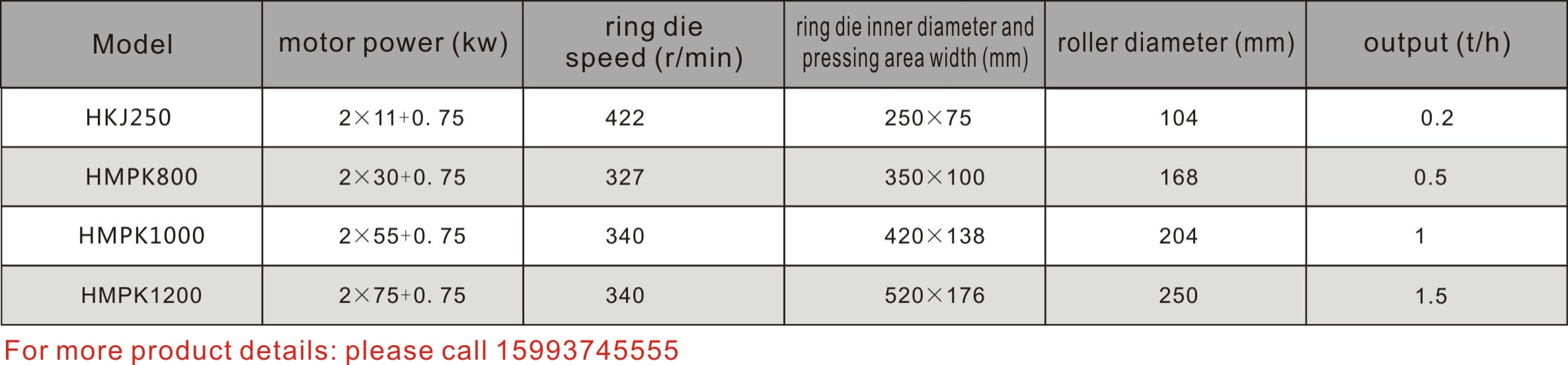

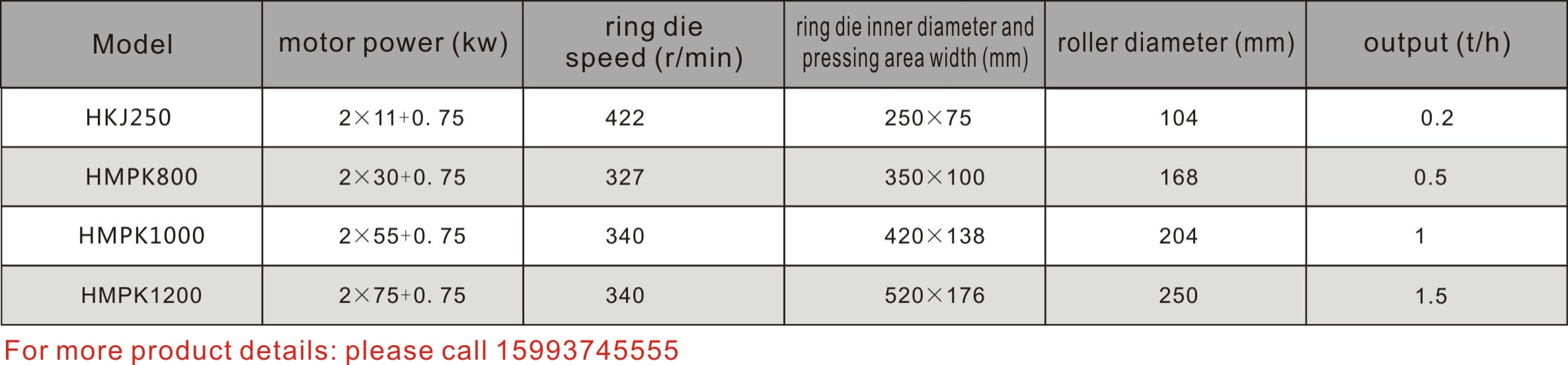

Technical parameters

-

- Commodity name: 508 pellet machine

- Production capacity: 3-15t/h

- Applicable materials: sawdust, straw, straw, rice husk, peanut shell, coconut shell, palm shell, etc.

- Applications: pastures, remote areas, etc.

Granulator is also called granulator, granulator, etc. There are two types of flat-mode pellet machines and ring-type pellet machines. The ring-molded pellet machines are divided into gear-driven pellet machines (CPM) and belt-driven pellet machines (UMT) from the transmission structure.

1. The main components of the flat die granulator are a flat round steel die and a set (2-4) of freely rotating pressing rollers with grooves. The raw material falls into the roller gap from top to bottom, and is rotated by the roller

Press into the die hole, extrude a long cylinder from below the die hole, and cut it into granules by a cutter. There are three transmission modes: drive roller, drive flat die and double drive. The characteristics of the flat die granulator are the

The structure is simple, the manufacture is relatively easy, and the cost is low, and it is suitable for pressing fibrous raw materials. However, the linear speed (circumferential speed) of the inner and outer diameters of the flat die is not equal during granulation, and it depends on the size of the raw material on the die.

Different centrifugal forces make the load on the working surface uneven. Therefore, the diameter of the flat die should not be too large, otherwise it will affect the uniformity of the finished product.

2. Ring die granulator and its working principle The ring die is a porous cylindrical cylinder, which is rotated by transmission. There are 2-4 free-rotating or driven auto-rotating rollers with grooves in the cylinder. The raw material enters the mold, that is, the rotating pressure roller is pressed into the workshop, embedded in the mold hole, extruded from the outer wall of the ring, and cut into cylindrical particles by the cutter

The main feature of the ring die granulator is that the linear speeds of the ring die and the pressing roller are equal everywhere. No extra friction,

All the pressure is used for granulation, so the efficiency is high. The ring die pellet machine is further divided into the difference between the ring die pellet machine and the vertical ring die

Down, and then turn 90 degrees to enter the granulation mold through forced feeding. The vertical ring die is placed in the flat mold, with the mouth upward, and directly enters the granulation mold from top to bottom. 2. Pressing method: The ring die is rotated by the die, the pressing wheel does not move, and rotates at high speed. The vertical ring die is that the pressure wheel rotates, and the die does not move.

-

1. It has the unattainable performance of traditional double belt drive and gear drive granulator;

2. Forged one-piece main shaft, the support rod of the pressing roller is cancelled, and the main shaft is optimized, which greatly increases the rigidity of the main shaft and the supporting rigidity of the pressing roller, and the pressing chamber can withstand super large

Torque, always ensure the axial parallelism of the pressure roller and the ring die, the equipment is aging, and the output is not reduced; the output is increased by 10-12% year-on-year, and the number of equipment maintenance is reduced;

3. Automatic refueling when the machine is turned on, the refueling time and refueling amount can be arbitrarily set by the user according to the oil and material conditions, so as to avoid major damage to the machine due to operator errors;

4. Stainless steel movable door, durable;

5. Pneumatic quick emergency discharge door to avoid burning out the motor or causing equipment damage;

6. Forged hollow shaft, durable;

7. Configuration: SKF bearing, Siemens motor, Schneider Electric, on-site touch screen operation cabinet.

-

The working principle of the HKJ series biomass granulator of straw animal husbandry machinery is similar to that of the SZLH series animal feed granulator. The action of the scraper is used to feed the two pressing zones in the ring die evenly into the wedge-shaped space formed by the two pressing rollers and the ring die. Extruded into the die hole of the ring die and formed in the die hole. Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into particles of the required length by the cutter, and then enters the next process.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry