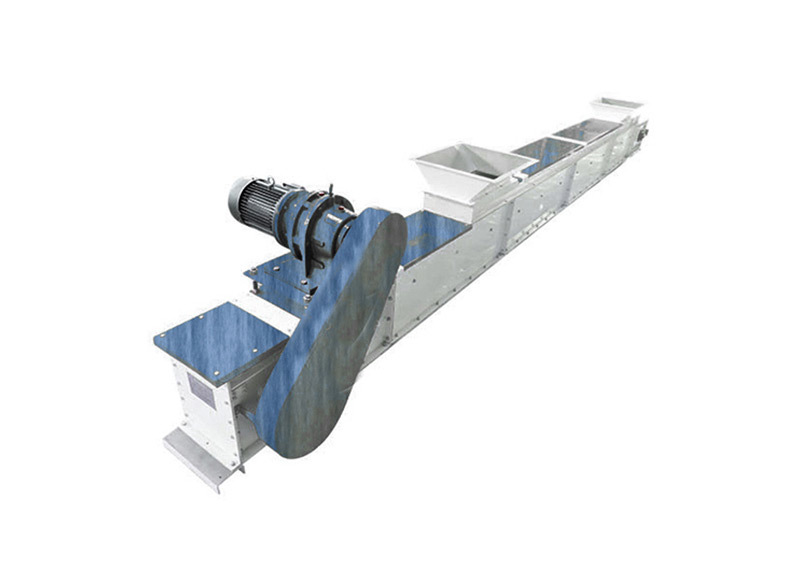

TGSS scraper conveyor

- Production capacity: 5-40t/h

- Applicable materials: Powder, granular and small block materials

- Applications: Feed mills, flour mills, rice mills, oil mills, starch mills, grain depots, ports and terminals

Classification:

Tel:

Introduction

-

When the motor is energized, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the moving direction, so that the internal friction between the materials is enough to overcome the frictional resistance between the material and the groove wall , so that the material can be transported in a continuous flow as a whole, reaching the

The material entering the feeding port is scraped along the conveying trough to the discharging port for discharging.

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

When the motor is powered on, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the direction of movement

The internal friction force between the materials is enough to overcome the frictional resistance between the materials and the tank wall, so that the materials can be conveyed in a continuous flow as a whole, so that the materials entering from the feed port are scraped along the conveying groove to the discharge port for discharge. the goal of.

-

Finished pellets

undefined

Features

-

- Commodity name: TGSS scraper conveyor

- Production capacity: 5-40t/h

- Applicable materials: Powder, granular and small block materials

- Applications: Feed mills, flour mills, rice mills, oil mills, starch mills, grain depots, ports and terminals

When the motor is energized, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the moving direction, so that the internal friction between the materials is enough to overcome the frictional resistance between the material and the groove wall , so that the material can be transported in a continuous flow as a whole, reaching the

The material entering the feeding port is scraped along the conveying trough to the discharging port for discharging.

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

When the motor is powered on, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the direction of movement

The internal friction force between the materials is enough to overcome the frictional resistance between the materials and the tank wall, so that the materials can be conveyed in a continuous flow as a whole, so that the materials entering from the feed port are scraped along the conveying groove to the discharge port for discharge. the goal of.

-

Working Principle

-

- Commodity name: TGSS scraper conveyor

- Production capacity: 5-40t/h

- Applicable materials: Powder, granular and small block materials

- Applications: Feed mills, flour mills, rice mills, oil mills, starch mills, grain depots, ports and terminals

When the motor is energized, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the moving direction, so that the internal friction between the materials is enough to overcome the frictional resistance between the material and the groove wall , so that the material can be transported in a continuous flow as a whole, reaching the

The material entering the feeding port is scraped along the conveying trough to the discharging port for discharging.

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

When the motor is powered on, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the direction of movement

The internal friction force between the materials is enough to overcome the frictional resistance between the materials and the tank wall, so that the materials can be conveyed in a continuous flow as a whole, so that the materials entering from the feed port are scraped along the conveying groove to the discharge port for discharge. the goal of.

-

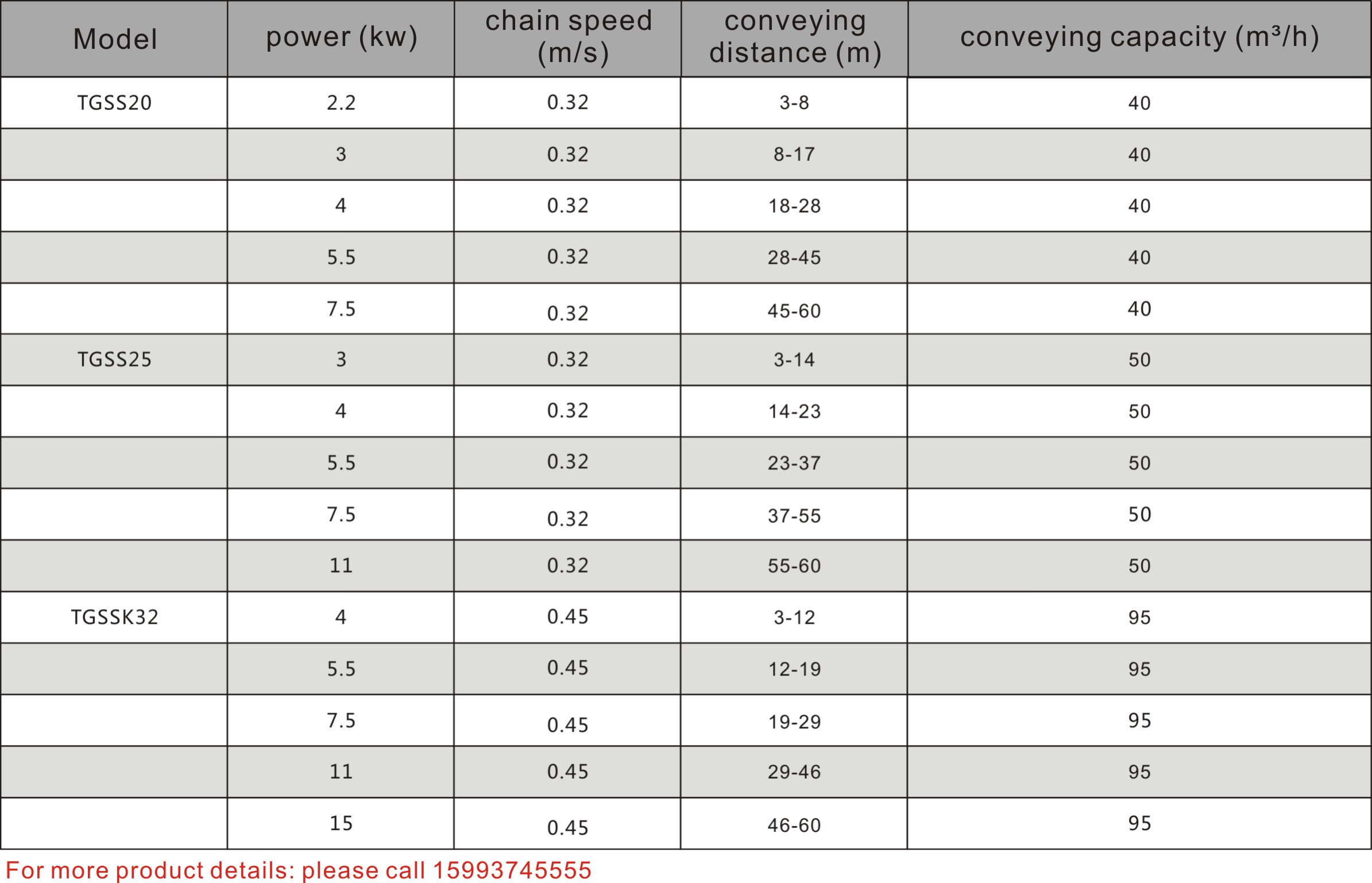

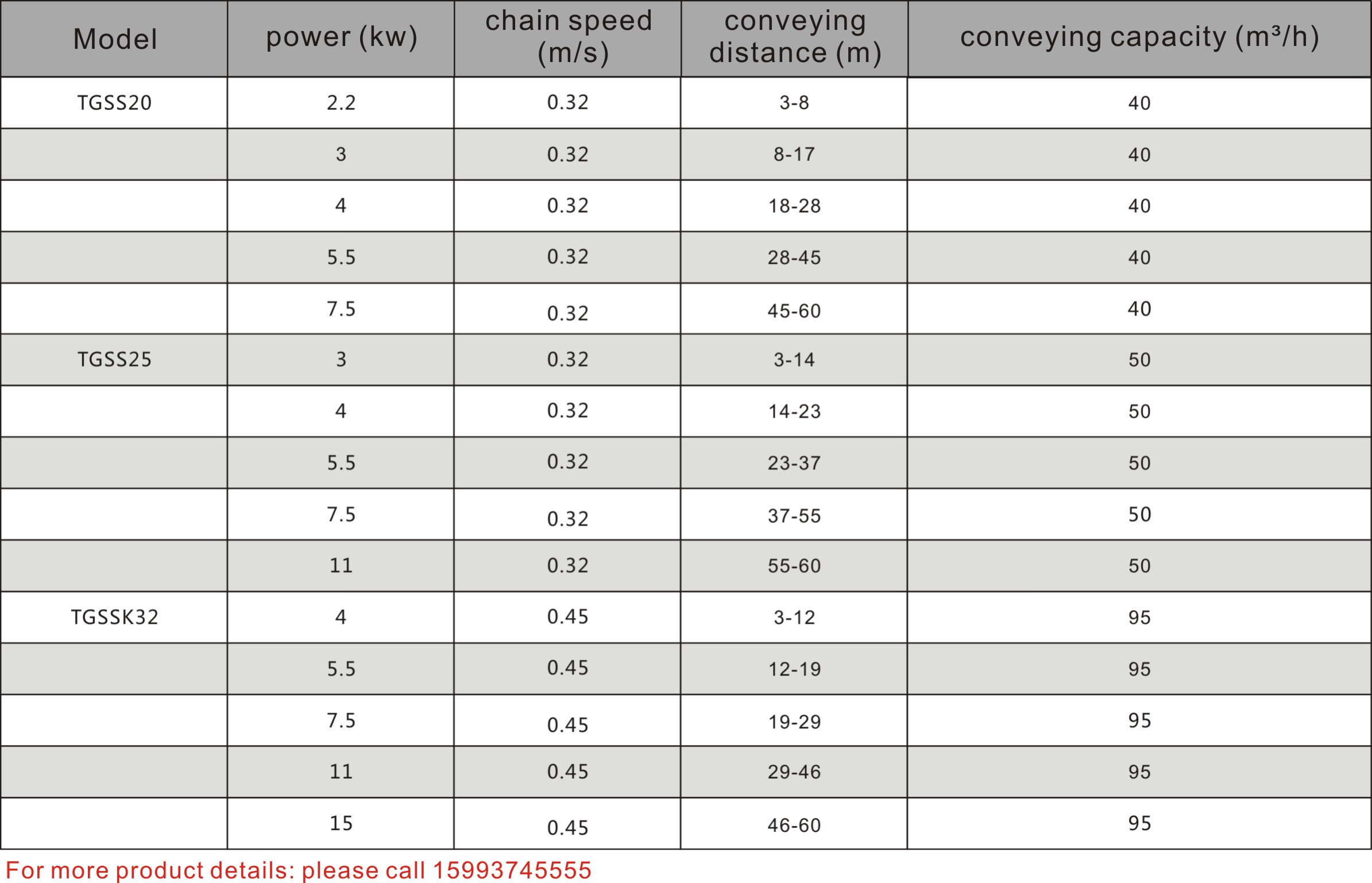

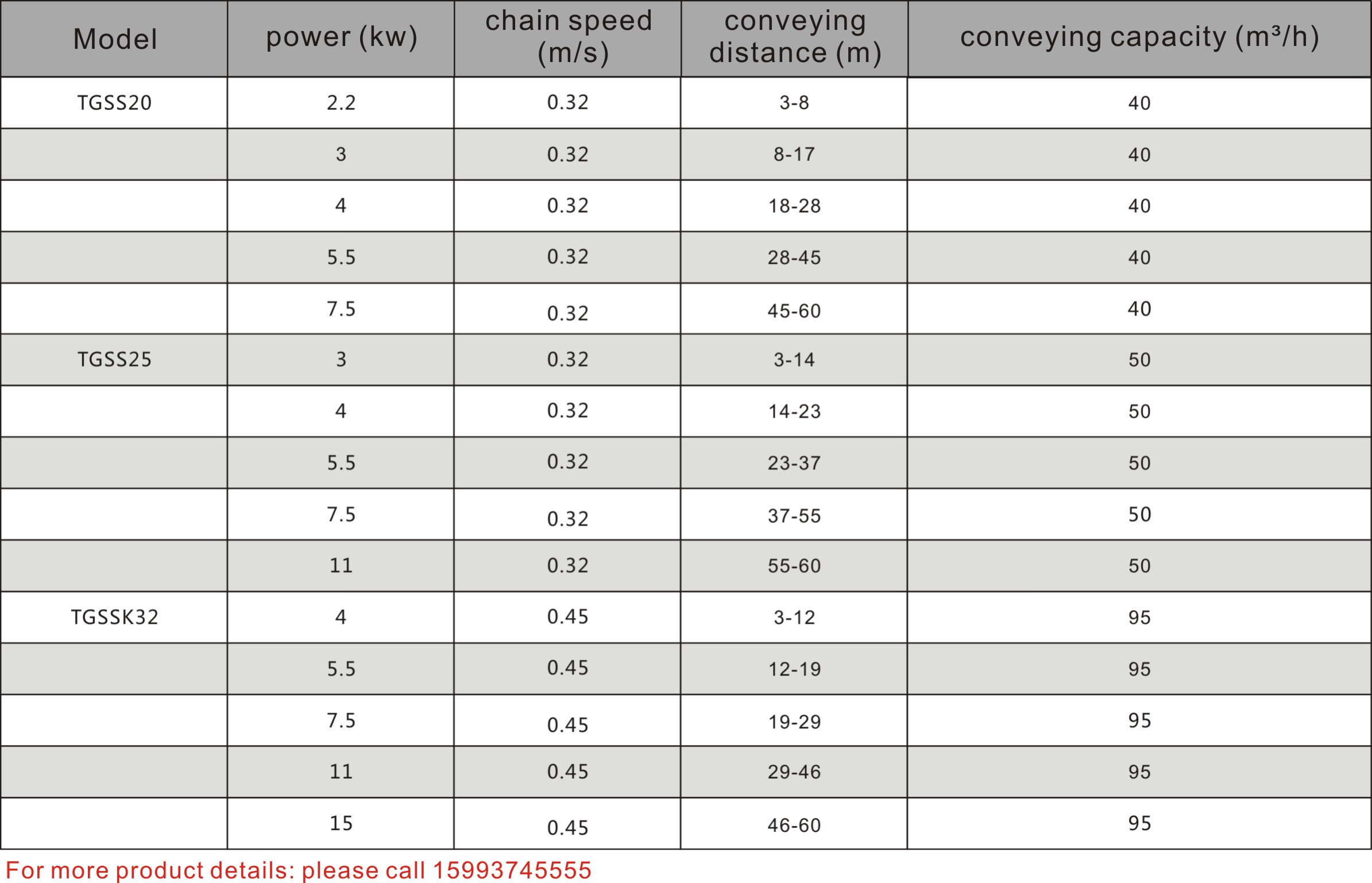

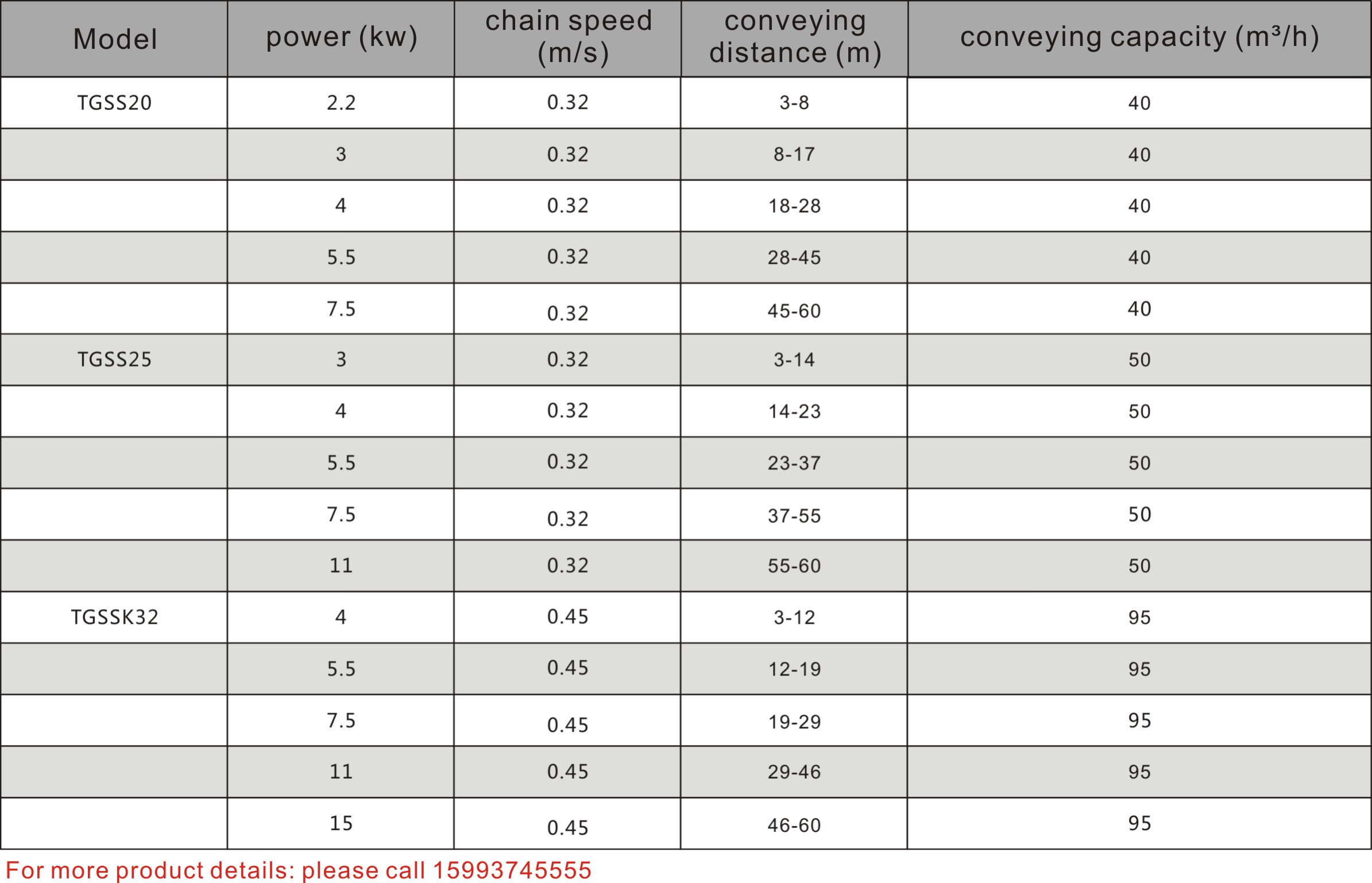

Technical parameters

-

- Commodity name: TGSS scraper conveyor

- Production capacity: 5-40t/h

- Applicable materials: Powder, granular and small block materials

- Applications: Feed mills, flour mills, rice mills, oil mills, starch mills, grain depots, ports and terminals

When the motor is energized, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the moving direction, so that the internal friction between the materials is enough to overcome the frictional resistance between the material and the groove wall , so that the material can be transported in a continuous flow as a whole, reaching the

The material entering the feeding port is scraped along the conveying trough to the discharging port for discharging.

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

1. The shaft end is sealed with new packing to ensure no material leakage.

2. The new patented anti-blocking mechanism is flexible, safe and reliable, and has good sealing performance.

3. There is a movable body at the tail to reduce the residue to a certain extent; a flexible scraper sheet and a return cup are arranged on the chain to greatly reduce the material residue at the head of the conveyor section.

4. Fully assembled structure design, easy to disassemble and replace.

5. The classic model, which has passed the EU CE safety certification, is widely used in the horizontal transportation of materials and small particles in feed, chemical, grain depots, ports, malt, oil and other industries.

-

When the motor is powered on, the drive wheel is driven by the reducer and the sprocket chain, and the drive wheel drives the scraper chain; the material is pushed by the scraper chain in the direction of movement

The internal friction force between the materials is enough to overcome the frictional resistance between the materials and the tank wall, so that the materials can be conveyed in a continuous flow as a whole, so that the materials entering from the feed port are scraped along the conveying groove to the discharge port for discharge. the goal of.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry