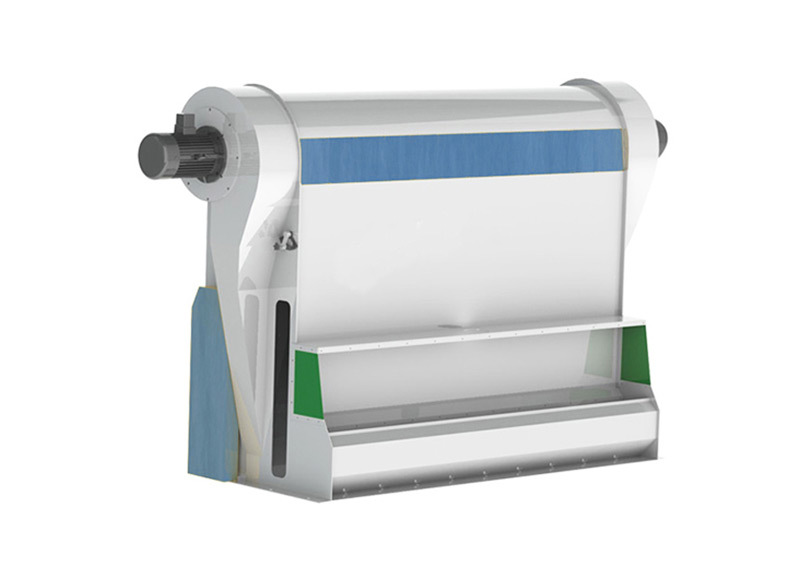

TFXH series circulating air separator

- Production capacity: 10-20t/h

- Applicable materials: Grains

- Applications: Feed field, etc.

Classification:

Tel:

Introduction

-

Straw Animal Husbandry Machinery TXFH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains by suction.

The product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal threshing machine. The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

1. TFXH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains and grains.

2. This product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal masher.

3. During the cleaning process of the equipment, the shaft end cylinder and the air closer form two closed winds, so that the light impurities can be removed smoothly.

4. The use of a large dust chamber can enhance the settlement effect.

5. The machine has its own fan and automatic air circulation suction to separate the light impurities in the grains, which has a good air selection effect.

-

The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

Finished pellets

undefined

Features

-

- Commodity name: TFXH series circulating air separator

- Production capacity: 10-20t/h

- Applicable materials: Grains

- Applications: Feed field, etc.

Straw Animal Husbandry Machinery TXFH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains by suction.

The product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal threshing machine. The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

1. TFXH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains and grains.

2. This product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal masher.

3. During the cleaning process of the equipment, the shaft end cylinder and the air closer form two closed winds, so that the light impurities can be removed smoothly.

4. The use of a large dust chamber can enhance the settlement effect.

5. The machine has its own fan and automatic air circulation suction to separate the light impurities in the grains, which has a good air selection effect.

-

The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

Working Principle

-

- Commodity name: TFXH series circulating air separator

- Production capacity: 10-20t/h

- Applicable materials: Grains

- Applications: Feed field, etc.

Straw Animal Husbandry Machinery TXFH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains by suction.

The product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal threshing machine. The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

1. TFXH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains and grains.

2. This product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal masher.

3. During the cleaning process of the equipment, the shaft end cylinder and the air closer form two closed winds, so that the light impurities can be removed smoothly.

4. The use of a large dust chamber can enhance the settlement effect.

5. The machine has its own fan and automatic air circulation suction to separate the light impurities in the grains, which has a good air selection effect.

-

The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

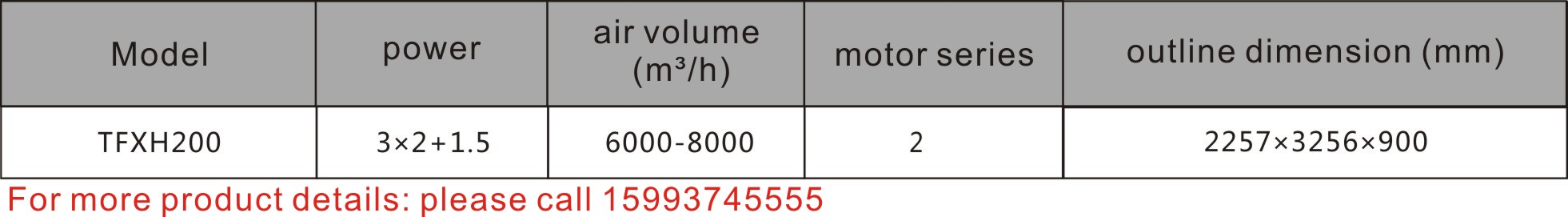

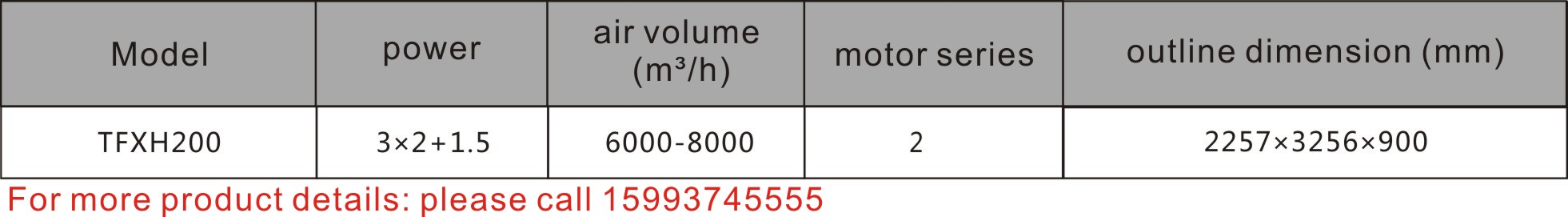

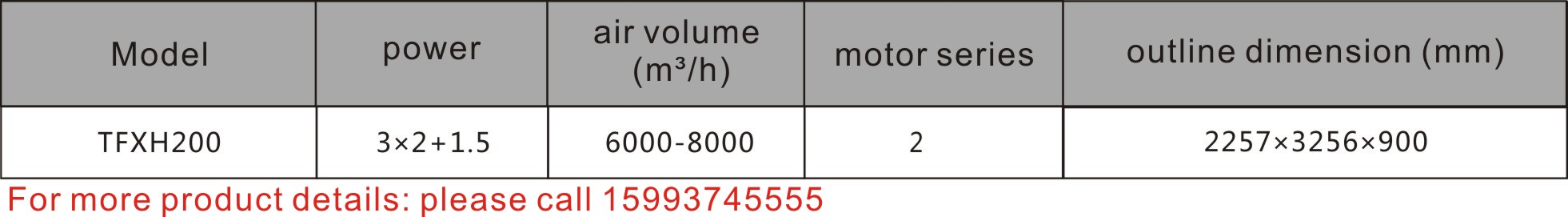

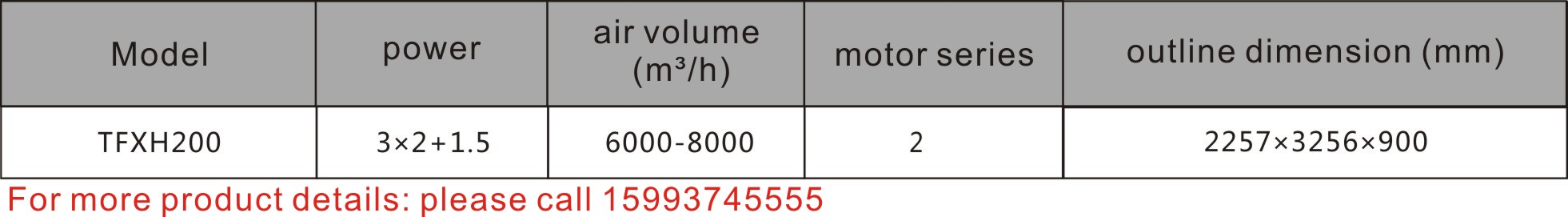

Technical parameters

-

- Commodity name: TFXH series circulating air separator

- Production capacity: 10-20t/h

- Applicable materials: Grains

- Applications: Feed field, etc.

Straw Animal Husbandry Machinery TXFH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains by suction.

The product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal threshing machine. The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

1. TFXH series circulating air separator is a cleaning equipment specially designed to separate low specific gravity impurities such as husk dust from grains and grains.

2. This product can be used alone or in combination with a vibrating screen, a plane rotary screen or a horizontal masher.

3. During the cleaning process of the equipment, the shaft end cylinder and the air closer form two closed winds, so that the light impurities can be removed smoothly.

4. The use of a large dust chamber can enhance the settlement effect.

5. The machine has its own fan and automatic air circulation suction to separate the light impurities in the grains, which has a good air selection effect.

-

The material falls into the feeding hopper. When the material accumulates to a certain height, due to the action of gravity, the spring suspended on the feeding valve will be pulled, thereby opening the discharge chute; The duct flows out and is evenly thrown over the entire width of the vertical air duct, and the flowing material is loosened. The clean and heavy materials fall vertically and are discharged out of the machine through the gravity valve. The impurities with light specific gravity are brought to the narrow passage of the cylindrical separator by the airflow. The outer wall of the dust collector falls into the dust collector with a sudden increase in space, and is discharged out of the machine through the air closer. The air is sucked in by the centrifugal fan through the interior of the cylindrical separator, and returned from the channel to the vertical air channel for recirculation.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry