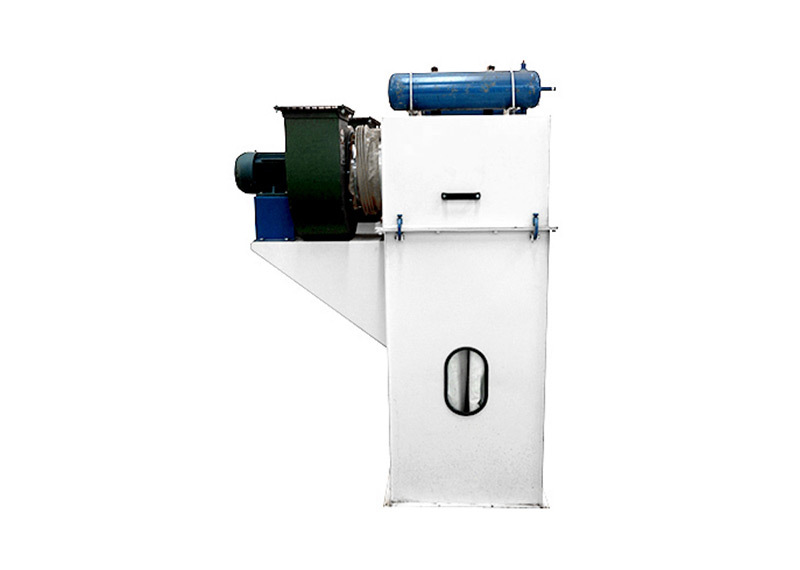

TBLM series pulse dust collector

- Production capacity: Handling air volume: 3000-24000m3/h

- Applicable materials: Silage, hay

- Applications: Food, feed processing, machinery, metallurgy, building materials, cement and other industries

Classification:

Tel:

Introduction

-

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

1. It adopts advanced flat cloth bag and box structure, which is mainly used for dust removal at the feeding port.

2. It has a unique blowing device and adopts the upper-opening dismantling bag structure, which is convenient for maintenance.

3. The filter area of each bag is as high as 1 square meter, which greatly reduces the floor space.

4. TDFK type high-pressure solenoid valve is adopted, the air release volume is increased, and the dust removal effect is good. The air inlet is placed on the ash hopper, which avoids the direct washing of the filter bag by the dust-laden air and improves the life of the cloth cylinder.

5. The patented technology of the bag quick loading and unloading mechanism is adopted to reduce the installation space requirements. The height of the upper space can be reduced by 1.5 meters, and the filter bags can be quickly removed one by one by opening the door.

-

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

Finished pellets

undefined

Features

-

- Commodity name: TBLM series pulse dust collector

- Production capacity: Handling air volume: 3000-24000m3/h

- Applicable materials: Silage, hay

- Applications: Food, feed processing, machinery, metallurgy, building materials, cement and other industries

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

1. It adopts advanced flat cloth bag and box structure, which is mainly used for dust removal at the feeding port.

2. It has a unique blowing device and adopts the upper-opening dismantling bag structure, which is convenient for maintenance.

3. The filter area of each bag is as high as 1 square meter, which greatly reduces the floor space.

4. TDFK type high-pressure solenoid valve is adopted, the air release volume is increased, and the dust removal effect is good. The air inlet is placed on the ash hopper, which avoids the direct washing of the filter bag by the dust-laden air and improves the life of the cloth cylinder.

5. The patented technology of the bag quick loading and unloading mechanism is adopted to reduce the installation space requirements. The height of the upper space can be reduced by 1.5 meters, and the filter bags can be quickly removed one by one by opening the door.

-

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

Working Principle

-

- Commodity name: TBLM series pulse dust collector

- Production capacity: Handling air volume: 3000-24000m3/h

- Applicable materials: Silage, hay

- Applications: Food, feed processing, machinery, metallurgy, building materials, cement and other industries

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

1. It adopts advanced flat cloth bag and box structure, which is mainly used for dust removal at the feeding port.

2. It has a unique blowing device and adopts the upper-opening dismantling bag structure, which is convenient for maintenance.

3. The filter area of each bag is as high as 1 square meter, which greatly reduces the floor space.

4. TDFK type high-pressure solenoid valve is adopted, the air release volume is increased, and the dust removal effect is good. The air inlet is placed on the ash hopper, which avoids the direct washing of the filter bag by the dust-laden air and improves the life of the cloth cylinder.

5. The patented technology of the bag quick loading and unloading mechanism is adopted to reduce the installation space requirements. The height of the upper space can be reduced by 1.5 meters, and the filter bags can be quickly removed one by one by opening the door.

-

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

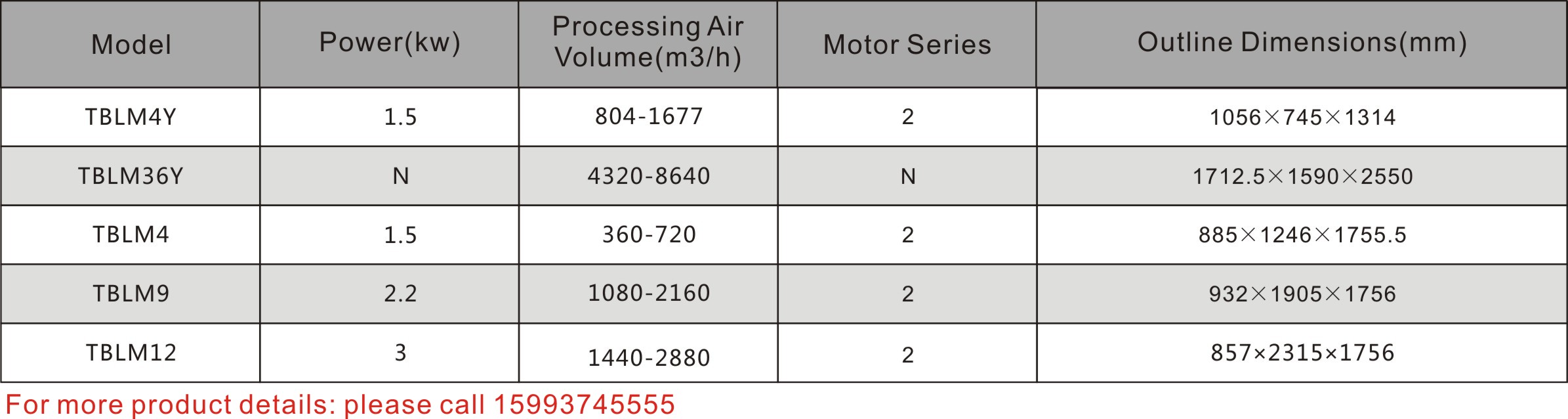

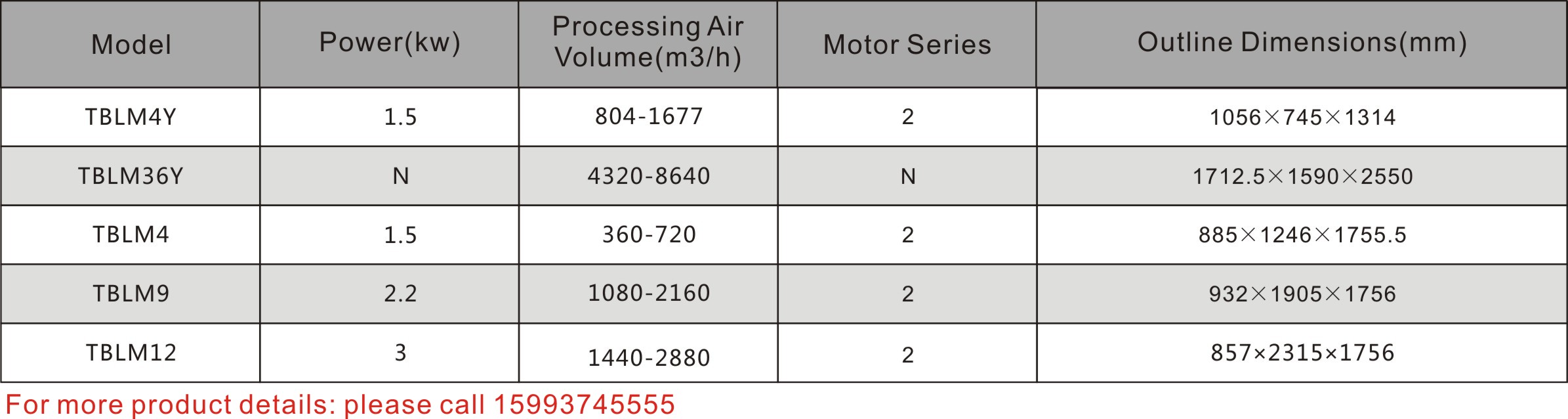

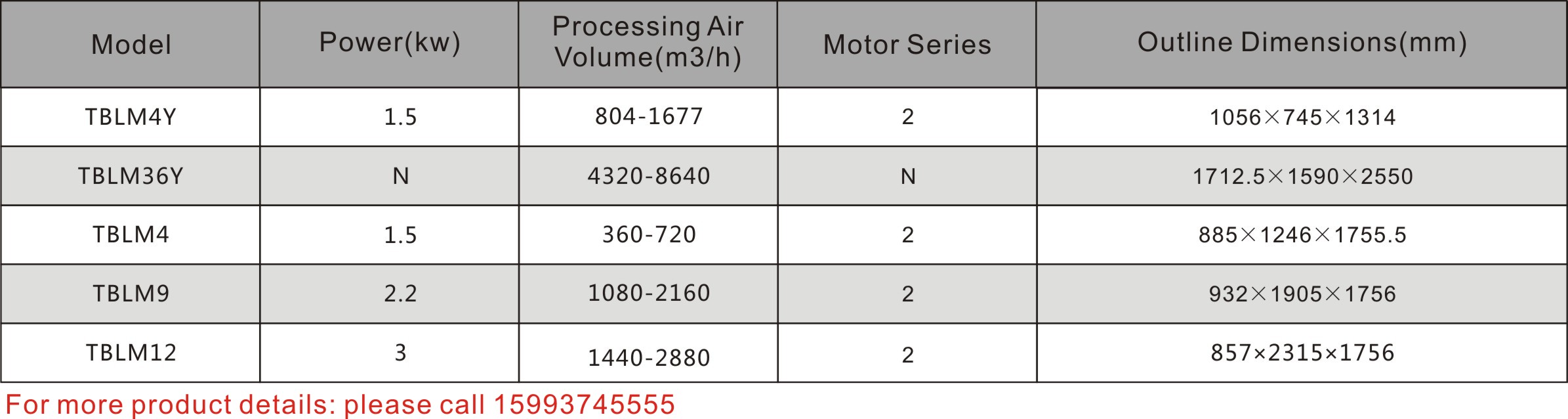

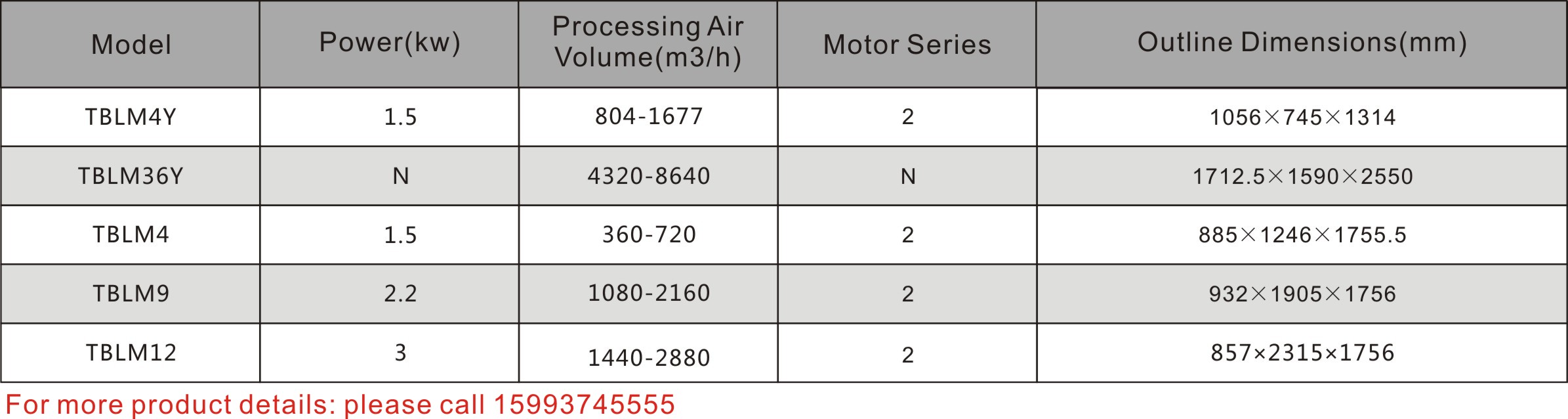

Technical parameters

-

- Commodity name: TBLM series pulse dust collector

- Production capacity: Handling air volume: 3000-24000m3/h

- Applicable materials: Silage, hay

- Applications: Food, feed processing, machinery, metallurgy, building materials, cement and other industries

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

1. It adopts advanced flat cloth bag and box structure, which is mainly used for dust removal at the feeding port.

2. It has a unique blowing device and adopts the upper-opening dismantling bag structure, which is convenient for maintenance.

3. The filter area of each bag is as high as 1 square meter, which greatly reduces the floor space.

4. TDFK type high-pressure solenoid valve is adopted, the air release volume is increased, and the dust removal effect is good. The air inlet is placed on the ash hopper, which avoids the direct washing of the filter bag by the dust-laden air and improves the life of the cloth cylinder.

5. The patented technology of the bag quick loading and unloading mechanism is adopted to reduce the installation space requirements. The height of the upper space can be reduced by 1.5 meters, and the filter bags can be quickly removed one by one by opening the door.

-

The dust-laden gas enters the lower box from the air inlet, the dust with larger particle size settles first, and the dust-laden gas with small particle size is filtered by the filter bag to become purified air, enters the upper box, and is discharged from the air outlet, and the dust accumulates on the filter. outside surface of the bag. When the accumulated dust reaches a certain amount, it must be cleaned. When cleaning the ash, the high-pressure air flow is triggered by the pulse controller according to the set requirements to sequentially trigger the air jet of each solenoid valve, and enters the filter bag through the nozzle hole. The air shutoff device is discharged, so the periodic pulse jet to clean the dust, so that the filter bag is in an effective filtering state to ensure the normal operation of the dust removal system.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry