FTMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Silage, hay

- Applications: Pasture, etc.

Classification:

Tel:

Introduction

-

FTMR fermented total mixed ration uses advanced compaction, sealing and packaging technology and stable microbial fermentation technology. The prepared TMR is compacted and sealed, and then subjected to microbial anaerobic fermentation treatment.

Straw FTMR series products can not only achieve long-term and stable preservation, but also use the company's mature Aspergillus oryzae aerobic fermentation technology products, which can significantly improve rumen health,

Improve the digestion and utilization of concentrated roughage and reduce the cost of weight gain.

The total mixed ration distribution center is an intelligent feeding center mode upgraded from the traditional fixed batching plant feeding mode. The main difference between the two modes is: in the traditional fixed batching Using the feeding belt, various materials, such as silage, concentrate, roughage, water, etc., need to be manually controlled to add ingredients, while the intelligent feeding center mode does not require personnel to directly participate in the ingredients, similar to the current popular robot cooking and cooking. , all processes are set in advance, the process is standardized, the personnel participation in the batching process is greatly reduced, and the whole process is a standard controllable process link. It has more efficient production, more accurate feeding, more labor saving, and lower production energy consumption costs. , Safer working environment and so on.

Feeding is a tedious job in the ranch, and the cost of feeding kuma accounts for 70-80% of the total operating cost of the ranch. If the cost can be reduced by 1-2% in this link, it is the profit of the ranch, which is also the concern of all ranch owners and investors. The intelligent feeding center can not only improve the processing efficiency of the pasture by 30-50%, but also reduce the processing cost by 50%, ensure the feeding accuracy, save labor, reduce the difficulty of management, and can realize and ensure the stable and safe feeding of large-scale farms. Feeding management is an important link in the entire traceability system of the animal husbandry industry. This system can be used not only in large farms, but also in small farms.

-

FTMR has undergone two-stage fermentation of oxygen consumption and anaerobicity, the digestibility of nutrients is increased by 10%, the digestion and absorption of beef cattle is enhanced, the monthly weight gain is easily over 80 kilograms, and the feed cost per kilogram of weight gain is reduced.

Cost-effective.

-

For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: FTMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Silage, hay

- Applications: Pasture, etc.

FTMR fermented total mixed ration uses advanced compaction, sealing and packaging technology and stable microbial fermentation technology. The prepared TMR is compacted and sealed, and then subjected to microbial anaerobic fermentation treatment.

Straw FTMR series products can not only achieve long-term and stable preservation, but also use the company's mature Aspergillus oryzae aerobic fermentation technology products, which can significantly improve rumen health,

Improve the digestion and utilization of concentrated roughage and reduce the cost of weight gain.

The total mixed ration distribution center is an intelligent feeding center mode upgraded from the traditional fixed batching plant feeding mode. The main difference between the two modes is: in the traditional fixed batching Using the feeding belt, various materials, such as silage, concentrate, roughage, water, etc., need to be manually controlled to add ingredients, while the intelligent feeding center mode does not require personnel to directly participate in the ingredients, similar to the current popular robot cooking and cooking. , all processes are set in advance, the process is standardized, the personnel participation in the batching process is greatly reduced, and the whole process is a standard controllable process link. It has more efficient production, more accurate feeding, more labor saving, and lower production energy consumption costs. , Safer working environment and so on.

Feeding is a tedious job in the ranch, and the cost of feeding kuma accounts for 70-80% of the total operating cost of the ranch. If the cost can be reduced by 1-2% in this link, it is the profit of the ranch, which is also the concern of all ranch owners and investors. The intelligent feeding center can not only improve the processing efficiency of the pasture by 30-50%, but also reduce the processing cost by 50%, ensure the feeding accuracy, save labor, reduce the difficulty of management, and can realize and ensure the stable and safe feeding of large-scale farms. Feeding management is an important link in the entire traceability system of the animal husbandry industry. This system can be used not only in large farms, but also in small farms.

-

FTMR has undergone two-stage fermentation of oxygen consumption and anaerobicity, the digestibility of nutrients is increased by 10%, the digestion and absorption of beef cattle is enhanced, the monthly weight gain is easily over 80 kilograms, and the feed cost per kilogram of weight gain is reduced.

Cost-effective.

-

For more product details: please call 15993745555

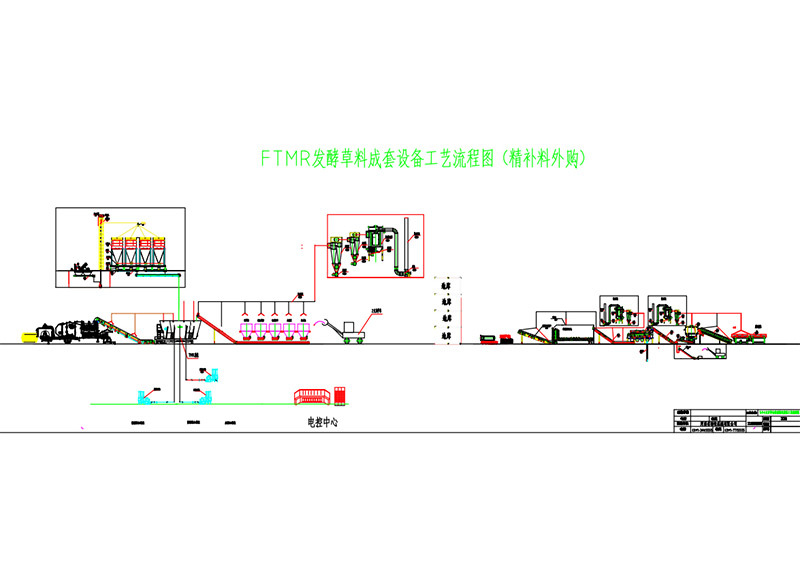

Working Principle

-

- Commodity name: FTMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Silage, hay

- Applications: Pasture, etc.

FTMR fermented total mixed ration uses advanced compaction, sealing and packaging technology and stable microbial fermentation technology. The prepared TMR is compacted and sealed, and then subjected to microbial anaerobic fermentation treatment.

Straw FTMR series products can not only achieve long-term and stable preservation, but also use the company's mature Aspergillus oryzae aerobic fermentation technology products, which can significantly improve rumen health,

Improve the digestion and utilization of concentrated roughage and reduce the cost of weight gain.

The total mixed ration distribution center is an intelligent feeding center mode upgraded from the traditional fixed batching plant feeding mode. The main difference between the two modes is: in the traditional fixed batching Using the feeding belt, various materials, such as silage, concentrate, roughage, water, etc., need to be manually controlled to add ingredients, while the intelligent feeding center mode does not require personnel to directly participate in the ingredients, similar to the current popular robot cooking and cooking. , all processes are set in advance, the process is standardized, the personnel participation in the batching process is greatly reduced, and the whole process is a standard controllable process link. It has more efficient production, more accurate feeding, more labor saving, and lower production energy consumption costs. , Safer working environment and so on.

Feeding is a tedious job in the ranch, and the cost of feeding kuma accounts for 70-80% of the total operating cost of the ranch. If the cost can be reduced by 1-2% in this link, it is the profit of the ranch, which is also the concern of all ranch owners and investors. The intelligent feeding center can not only improve the processing efficiency of the pasture by 30-50%, but also reduce the processing cost by 50%, ensure the feeding accuracy, save labor, reduce the difficulty of management, and can realize and ensure the stable and safe feeding of large-scale farms. Feeding management is an important link in the entire traceability system of the animal husbandry industry. This system can be used not only in large farms, but also in small farms.

-

FTMR has undergone two-stage fermentation of oxygen consumption and anaerobicity, the digestibility of nutrients is increased by 10%, the digestion and absorption of beef cattle is enhanced, the monthly weight gain is easily over 80 kilograms, and the feed cost per kilogram of weight gain is reduced.

Cost-effective.

-

For more product details: please call 15993745555

Technical parameters

-

- Commodity name: FTMR fermentation complete equipment

- Production capacity: 200 tons per day, 500 tons per day, etc.

- Applicable materials: Silage, hay

- Applications: Pasture, etc.

FTMR fermented total mixed ration uses advanced compaction, sealing and packaging technology and stable microbial fermentation technology. The prepared TMR is compacted and sealed, and then subjected to microbial anaerobic fermentation treatment.

Straw FTMR series products can not only achieve long-term and stable preservation, but also use the company's mature Aspergillus oryzae aerobic fermentation technology products, which can significantly improve rumen health,

Improve the digestion and utilization of concentrated roughage and reduce the cost of weight gain.

The total mixed ration distribution center is an intelligent feeding center mode upgraded from the traditional fixed batching plant feeding mode. The main difference between the two modes is: in the traditional fixed batching Using the feeding belt, various materials, such as silage, concentrate, roughage, water, etc., need to be manually controlled to add ingredients, while the intelligent feeding center mode does not require personnel to directly participate in the ingredients, similar to the current popular robot cooking and cooking. , all processes are set in advance, the process is standardized, the personnel participation in the batching process is greatly reduced, and the whole process is a standard controllable process link. It has more efficient production, more accurate feeding, more labor saving, and lower production energy consumption costs. , Safer working environment and so on.

Feeding is a tedious job in the ranch, and the cost of feeding kuma accounts for 70-80% of the total operating cost of the ranch. If the cost can be reduced by 1-2% in this link, it is the profit of the ranch, which is also the concern of all ranch owners and investors. The intelligent feeding center can not only improve the processing efficiency of the pasture by 30-50%, but also reduce the processing cost by 50%, ensure the feeding accuracy, save labor, reduce the difficulty of management, and can realize and ensure the stable and safe feeding of large-scale farms. Feeding management is an important link in the entire traceability system of the animal husbandry industry. This system can be used not only in large farms, but also in small farms.

-

FTMR has undergone two-stage fermentation of oxygen consumption and anaerobicity, the digestibility of nutrients is increased by 10%, the digestion and absorption of beef cattle is enhanced, the monthly weight gain is easily over 80 kilograms, and the feed cost per kilogram of weight gain is reduced.

Cost-effective.

-

For more product details: please call 15993745555

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry