Introduction of 3 tons per hour drying plant

Time:

2023-01-04

一(yī), the basic process parameters and process conditions design

(1) Basic process parameters

1. Material name: forage grass (40-50MM length after harvest)

2. Initial moisture: 77.5%

3. Final moisture: 15%

4. Processing capacity: 3T/h

5. Heat source: natural gas

(2) Process condition design

1. Drying method: pasture special net hot air drum drying

2. Material and hot air contact mode: piercing type

3. Inlet air temperature: 220-280℃

4. Exhaust air temperature: 70-90℃

5. Product discharge mode: flowing discharge

6. System material requirements: Q235B, No. 45 steel

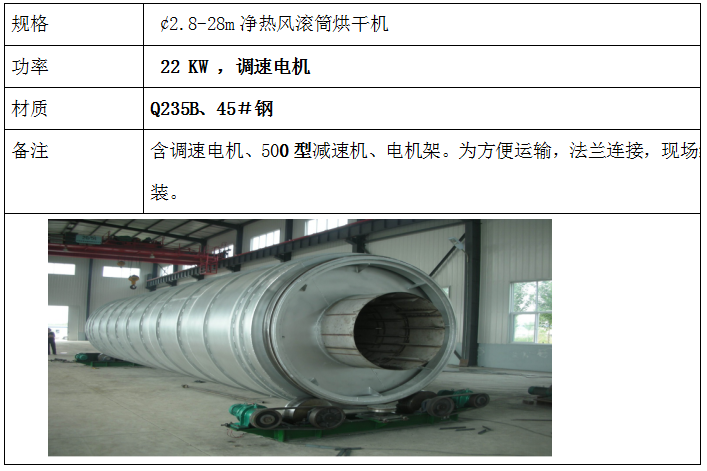

7. Dryer selection: ¢2.8-27m

二、Calculation of main parameters

(1) Determined parameters

1. According to the processing capacity of 11T/h, the dry product is about 3T/h output, and it is calculated that: water evaporation: W water = 8T/h

2. Wet material processing volume: W original = 11T/h

3. Wet material water content ω1=77.5%

4. Product water content ω2=15%

5. Inlet air temperature t1=200℃-280℃

6. Exhaust air temperature t2=60℃-90℃

(2) Atmospheric conditions

1. Atmospheric pressure: standard 101.325KPa (760mmHg)

2. Average ambient temperature: 20℃ (take the value)

3. Average relative humidity: 80% (take the value)

4. Check the table can be obtained: the annual average air moisture content d1 = 0.01 water / kg dry air

三、Drying equipment selection reference

According to the calculation, it needs to process 11T grass per hour, the water evaporation volume is 8T/h, the dry grass is about 3T, the over grass volume is about 110 cubic meters per hour. The inlet air temperature is set to 200℃-280℃, and the evaporation intensity is at least 50.1KG/m³ with the special drum dryer for forage, according to this calculation: the required drum volume of 161.3m³ can meet the drying requirements. Therefore, it needs ¢2.8-27m (166 cubic meters) net hot air drum dryer can meet the drying requirements.

Heat balance calculation: drying should go out the water content: W1= ( W original-ω1 )=11000×(77.5%-15%)÷(100%-15%)=8088.2kg

Vaporization potential of water at 60°C rW1= 560cal/kg

Heat necessary for drying: Q1=W1* rW1+G0 *C1(ↀ1-ↀ2)=8088.2×560+11000×0.8×(60-20)=4881392Kcal

Take the heat loss 18%, then need a'w heat Q1 = 1.18Q1 = 1.18 × 4881392Kcal = 5760042Kcal

Take the specific heat of air CK = 0.24Kcal/kG

Then the amount of hot air needed L1=Q1 /CK (t1-t1´)=5760042÷0.24÷(280-60)=109091.75kg

Air consumption: GM=Q1 /ɧQD =5760042÷0.95%÷8000=757.9m³

Heat consumption calculation: qH=Q1 /△W1=5760042÷8593.75=670.2Kcal/kG.H2O

Dryer size selected: heat exchange volume in the dryer: Qj=Q1=5760042Kcal

Logarithmic temperature difference: △TLn=[(280-20]-( 90-20)/1N[(280-20]-( 90-20)=255℃

The heat exchange coefficient in the dryer is: K=140Kcal/m³℃

Dryer volume: V1=Q1 /ΔTLn /K=5760042÷255÷140=161.3m³

Take the dryer diameter of 2800㎜, then the length L=161.3÷3.14×1.4×1.4=26.2m

Calculation of drying strength

Drying precipitation: △W1 =8088.2kg.

Dryer volume: 161.3m³

Drying intensity: K=8088.2÷161.3=50.1KGH2O/m³

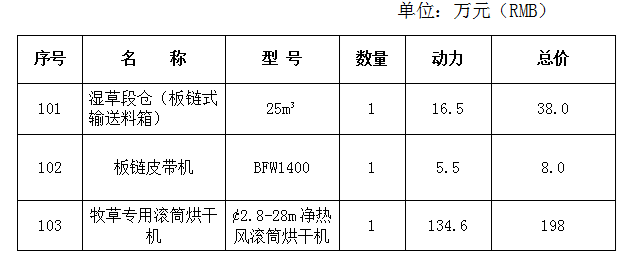

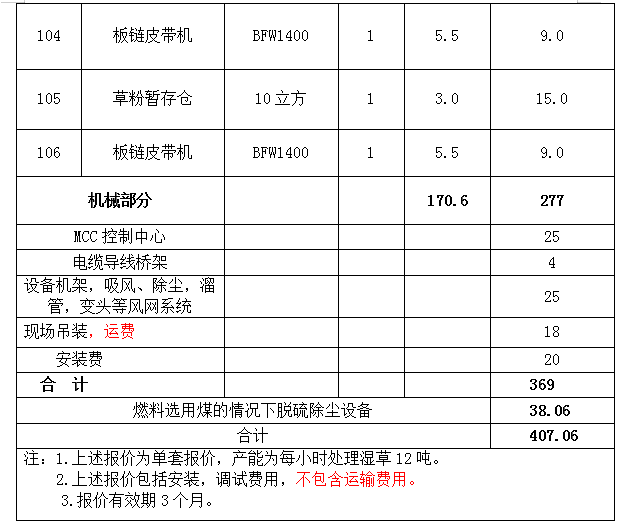

Cost Accounting

1.Electricity consumption

Total power of drying equipment 170.6KW, electricity consumption per ton of hay 56.86KW, calculated according to 1 yuan per degree, 56.86 yuan per ton

2. Fuel (natural gas)

Gas material per hour: 757.9m³, each ton of hay consumes 252.6m³ of natural gas, calculated according to 2.5 yuan per m³, equivalent to 631.5 yuan.

3. Labor

The labor cost is 6.25 RMB per ton for 3 people, 150 RMB per person per day, 24 hours per day, 3 shifts.

Total drying cost per ton is 302.36 RMB, (757.9m³×24 hours×2.5 RMB/m³+170.6 degrees×1 RMB/degree+150 RMB×3 people/day)÷72 tons=640.2 RMB/ton

In the case of fuel selection of coal

1.Electricity consumption

Total power of drying equipment 170.6KW, electricity consumption per ton of hay 56.86kW, calculated according to 1 yuan per degree, 56.86 yuan per ton

2.Fuel

Fuel consumption is about 700KG per hour. 233kg of coal is consumed per ton of hay, calculated at RMB 1000 per ton, which is RMB 233.

(Can we use natural gas, what if converted to gas?)

3. Labor

Labor is about 6 people. Calculated at 150 yuan per person per day, 24 hours per day, three shifts, 12.5 yuan per ton of labor costs required

Total cost per ton of drying is 302.36 yuan

Main technical parameters of drying equipment

(1) Equipment name

Forage special hot air drum dryer

(2) Equipment use conditions and requirements

1. Use location.

2. for drying: pasture grass

3. The equipment is made of Q235B and adopts flowing operation;

(3) Requirements for peripheral conditions

Electricity: 380V, 50HZ

四、Equipment principle overview and operation description

(1) Equipment Overview

Net hot air drying.

In order for the material not to be polluted, it is necessary to use the net hot air way of drying, and the method usually used is to dry the material when heat exchange through the radiator. Heat energy loss is huge and the drying cost is too high, our factory adopts the method of heat exchange inside and outside for this problem, while the heat exchanger outside the host is used as baking clean hot air, the heat sink is set inside the host, that is, after the external heat exchanger is used, a large amount of mixed heat heat energy is not directly discharged, but enters the internal multi-bin rotary radiator of the host, and is discharged after reuse. So that the material is directly baked on the heat sink device, which greatly improves the utilization rate of heat energy, reduces the drying cost and improves the economic efficiency.

Multi-bin equipment.

It is a single drum optimized for multiple independent working bins, which can make the materials fully occupy the drying space, centralize drying to disperse drying, and increase the drying area of the hot cylinder, effectively improving the utilization rate of heat energy. Due to the presentation of the upper, middle, lower, left and right are independent drying bins to make the host circumference weight balance, eliminating the disadvantages of the host bias sink.

Multi-swing equipment.

Because of the multi-turn function, the invisible length of the main machine increases several times. The material can be dried at high temperature for several times, and the drying length and drying time of the material inside the main machine can be extended, saving the manufacturing cost and the installation area of the equipment.

(2) Technical features

1. In the drying process, the hot air enters from the air inlet of the drum, makes full contact with the material and passes through the material, takes away the moisture, and discharges from the air outlet.

2. The material of the whole equipment is made of Q235B carbon steel which meets the requirements; the bottom of the inner cavity is fully welded, the internal design is scientific and reasonable, and there is no residue in the discharge, and the outer wall of the drum adopts special insulation material to make the internal temperature of the drum not dissipate, so as to improve the drying efficiency and save the drying cost.

3. Adopt completely closed structure, except for the inlet duct and the damp exhaust duct, no additional external duct, thus ensuring that the material is not polluted, improving thermal efficiency and working conditions.

4. Adopt unique air supplying and even wind device, which not only improves the relative speed between the material and hot air, improves the drying rate, but also makes the material dry evenly and uniformly.

5. All key components are adopted from domestic and foreign famous manufacturers to ensure the long-term normal operation of the equipment.

6. The rotating speed of the drum adopts frequency conversion, and the internal temperature of the drum can be intuitively displayed on the electric control box, which can easily adjust the drying degree of the materials.

7. All circulating fans are centrifugal fans, with low energy consumption, high wind pressure and high hot air penetration rate.

(3) Reliability and maintenance of the system

The machine is low-speed operation equipment, and the whole machine is closed structure, and effective insulation measures are taken, less wearing parts, stable and reliable operation of the equipment; conveyor belt adopts roller drive wheel transmission to ensure the stability of the equipment in operation. The drying temperature is automatically controlled and the dwell time is continuously adjustable, which enhances the operation flexibility of the equipment. Maintenance is mainly in the bearings and reducer, regular filling of grease (oil) to ensure that the transmission mechanism is not affected by the temperature rise but to ensure its continuous operation; timely drive wheel up tight, to ensure that the entire drying system works smoothly

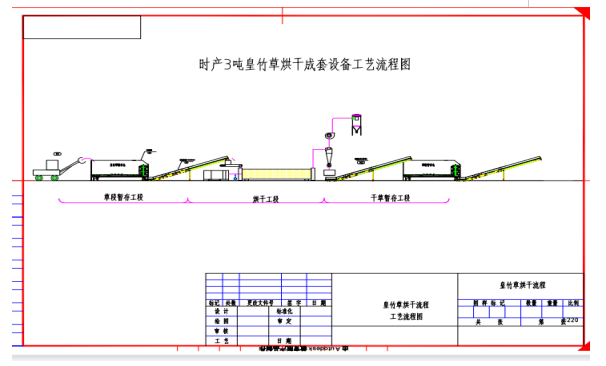

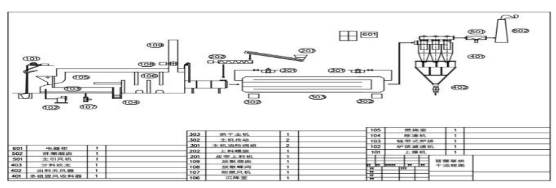

五.Forage drying process and flow chart: The grass section is put into the silo through the grass catcher, further through the plate chain belt machine feeding hopper into the dryer before the temporary storage bin, through the feeder into the dryer, the feeder is equipped with material layer controller, equal thickness of the material flow through the feeder wind shutter to join the dryer inlet, at the dryer inlet and the high temperature hot flue gas from the hot air furnace full contact and together into the multi-ring drum dryer, after three trips of mass heat exchange so as to complete the drying of materials, after drying the materials into the multi-group cyclone separator, dry materials through the discharge wind shutter discharge, while the tail gas from the cyclone collector directly into the atmosphere.

The grass section is put into the silo through the grass catcher, further through the plate chain belt machine feeding hopper into the dryer before the temporary storage bin, through the feeder into the dryer, the feeder is equipped with material layer controller, equal thickness of the material flow through the feeder wind shutter to join the dryer inlet, at the dryer inlet and the high temperature hot flue gas from the hot air furnace full contact and together into the multi-ring drum dryer, after three trips of mass heat exchange so as to complete the drying of materials, after drying the materials into the multi-group cyclone separator, dry materials through the discharge wind shutter discharge, while the tail gas from the cyclone collector directly into the atmosphere.

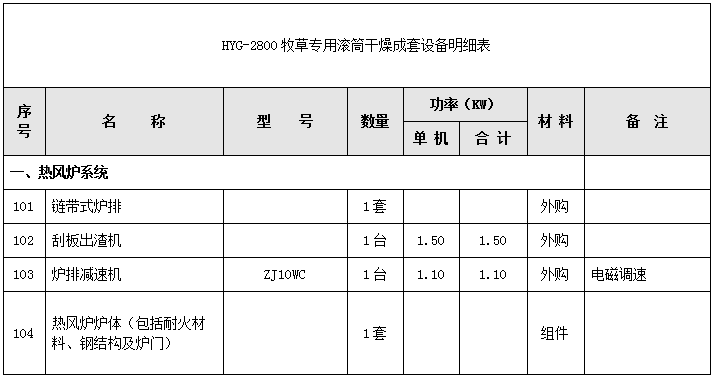

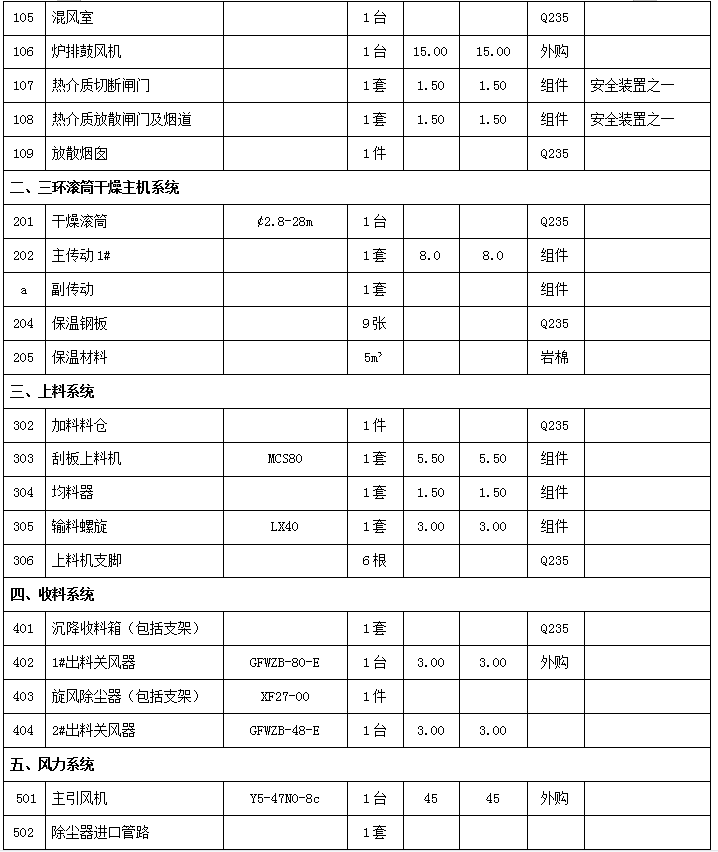

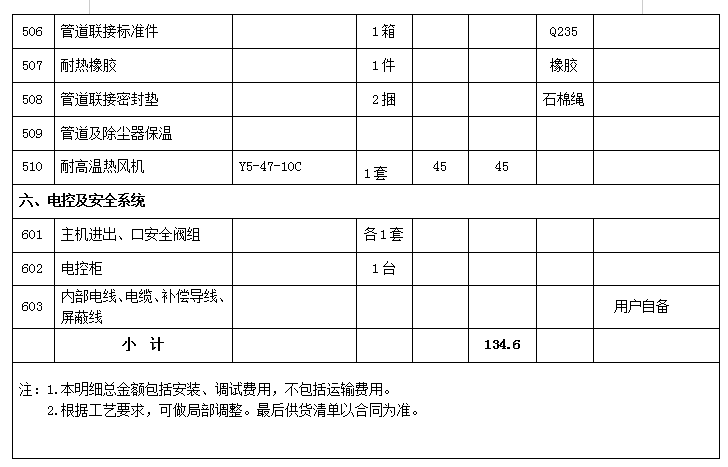

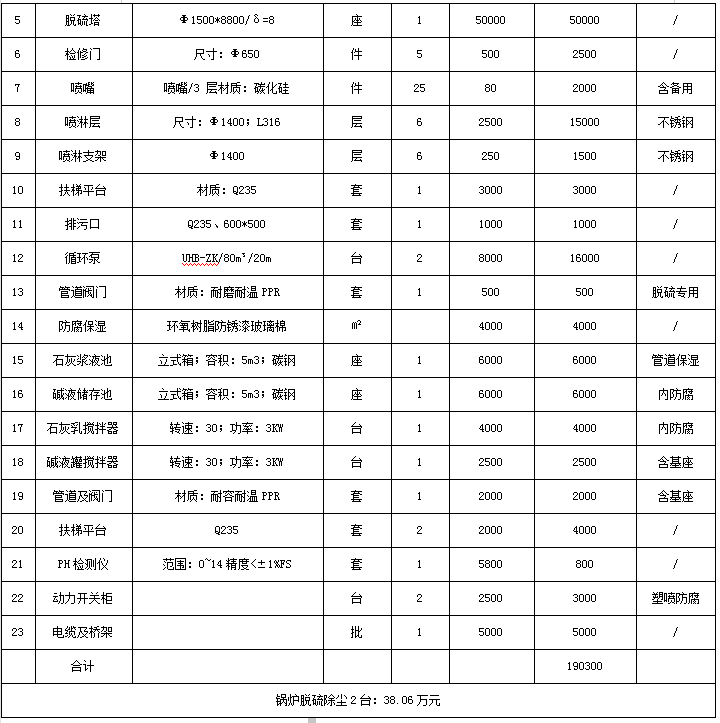

六、Quotation Summary

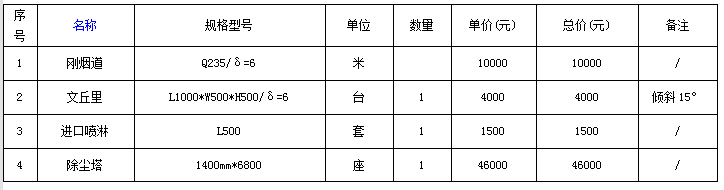

鍋爐脫硫除塵成套設備

鍋爐脫硫除塵成套設備

七:産品圖片

Hot air furnace

The hot air furnace with drying system is a mechanical chain belt grate hot air furnace with energy-saving combustion arch and high temperature settling chamber after the furnace, and the furnace is equipped with hot air cut-off gate, which can cut off the hot flue gas quickly in case of equipment failure.

Dryer

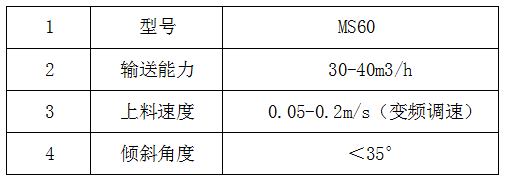

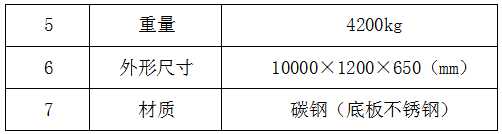

Scraper feeding machine

The scraper feeder adopts the upper feeding method, and the scraper is equipped with an equalizer, which can control the thickness of the material layer and break up most of the materials.

Technical specification response table of feeding scraper

Cyclone Receiver

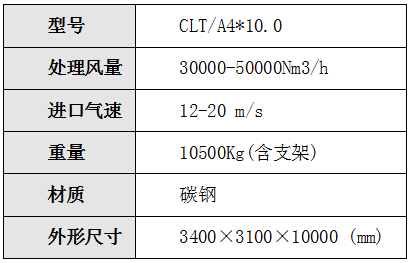

Cyclone Receiver Technical Specification Response Table

Main induced draft fan

The main induced draft fan is a high-efficiency, low-noise fan with vibration-damping pedestal and access door.

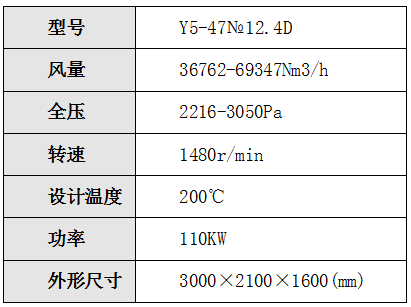

Fan technical specifications response table

Electronic control system

①The electric control system executes the following standards.

1.1 GB/T4278-2000 "Graphic Symbols for Electrical Diagrams

1.2 GB/5226-85 "General technical conditions for machine tool electrical equipment".

1.3 GB/6988-1997 "Electrical Drawing Circuit Diagram".

② Overview

Electrical control system by the feeding scraper, even feeder, feeding strand, grate blower, drying host, discharge shutter, induced draft fan and other single machine control circuit composition. Each motor is equipped with short circuit, overload, loss of voltage protection and alarm circuit. Among them, the induced draft fan and scraper loading machine adopt frequency conversion speed control. 15KW or more motor starting method adopts voltage reduction starting.

③Features

The control panel is equipped with digital temperature meter, which indicates the host inlet temperature and host outlet temperature respectively. When the above temperature measuring point exceeds the set value, the regulator outputs alarm signal, while the alarm bell rings and the red light is on, prompting the operator to deal with it in time. When the outlet temperature of the main machine is rising, the fuel quantity of the combustion charging machine is controlled to reduce the fuel quantity to make the outlet temperature fall; when the outlet temperature is falling, the fuel quantity of the combustion charging machine is controlled to increase the fuel quantity to make the outlet temperature rise. So many times of comparative fuzzy operation, finally make the outlet air temperature always keep within a certain set temperature difference zone, so as to realize the automatic monitoring of product quality and ensure the final moisture content of the product, and can be switched manually/automatically by the switch. Please refer to the automatic control system program flow chart and automatic control schematic diagram.

Automatic fire-fighting system: When the outlet temperature exceeds the upper limit of the set value, the automatic cooling system starts to work, and the fire-fighting system stops working when the temperature drops to the normal value. This fire-fighting system is equipped with two types of manual/automatic operation.

Automatic alarm system: When there is a fault of electrical components, the electrical alarm device starts to work, while the electric bell rings and the yellow light is on, prompting the operator to remove the fault in time, and after the fault is removed, the alarm is lifted. Please refer to the schematic diagram of fault and over-temperature alarm system and the schematic diagram of fire-fighting circuit.

Variable frequency speed control is another feature of this set of equipment. Energy saving and consumption reduction is one of the important means to reduce production costs, and the use of frequency converter to regulate the air volume of the fan can completely solve the problem.

Soft start function is another advantage of inverter energy saving. In general, the starting current of the motor is about equal to (4-7) times the rated current, even if the use of voltage reduction and other ways to start also in more than 2 times, which will cause serious impact on mechanical and electrical equipment and power grid, the high current and vibration generated when starting will shorten the service life of the equipment. After using the inverter, because the inverter has a soft start function, that is, the starting current starts from zero, which reduces the impact on the power grid and extends the service life of the equipment. The one-time investment of the equipment can generally be fully recovered in 9 to 12 months of production.

This set of equipment also has the characteristics of easy operation and simple maintenance.

④ Quality assurance of electric control system

In order to ensure that the electric control system works safely and reliably for a long time, the following requirements must be met when purchasing electrical components.

a. The purchased product manufacturers have passed ISO9001 quality system certification.

b. The purchased products have passed the safety certification of China Electrical Products Certification Committee and "3C" national compulsory certification.

Automatic control point:

First set the allowable temperature of dry materials, in the production process, no matter how the humidity of wet materials and hot air temperature changes, the automatic control system will automatically adjust the frequency of the scraper on the material humidity changes (material layer height is certain) that is, the speed, through the control of the amount of material to ensure the initial dry materials allowable humidity.

八、Technical Services:

1. After the contract comes into effect, the foundation drawings will be provided within fifteen days, and Party A will make its own foundation foundation and pre-buried parts according to the drawings.

2. Party B is responsible for installation.

3. Party B is responsible for the commissioning and start-up of the equipment.

4. to do technical training for Party A's operators and provide equipment operation manual. 5.

5. The equipment warranty period is one year. 6.

6. During the warranty period, if the equipment is damaged, Party B is responsible for repairing or replacing (except for perishable parts such as belts and sealing tapes), except for the loss caused by improper operation of Party A. However, Party B still provides timely technical service.

7. after the end of the warranty period, still provide effective technical advice at any time. The parts of the equipment, if damaged, will be repaired and replaced at cost. (Foreign countries are negotiated separately)

8. If the loss of the equipment caused by improper operation of Party A or modification of the equipment without the consent of Party B, it is not included in the warranty. However, Party B still provides technical services to repair or replace at cost. (Negotiable abroad)

九、Payment Method

1、The first payment (deposit) is 30% of the total amount, and the contract will be effective.

2、The second payment is 65% of the total purchase price, after the payment reaches the account of the supplier, the supplier will deliver the goods.

3, 5% of the total purchase price of the equipment for the warranty, the normal operation of the equipment after a production cycle, a one-time payment.

Henan Province Straw Shepherd Machinery Co.

Tel: 0391-3805555

Fax: 0391-7715555

Hotline:400-6013-321(Toll-free)

Website: www.jiemujixie.com.

Address: Shishihe Road, Xiuwu County Industrial Gathering Area, Henan Province

Zhao always have a few questions please clarify:

1、 Are there any requirements for the location of the whole system?

Far from villages, schools

2, the whole set of equipment needs to cover an area of at least how much, and how large an area of the plant, how large an area of the proposed warehouse, other functional rooms and the corresponding height and building requirements, etc.

Drying workshop covers an area of: length * width: 90 m * 28 m: height 8 m

Finished product storage to keep temporary storage of grass after drying for 3 days, roughly 216 tons of hay. 1 ton of hay 7-7.2m³, bale size: 1.2m*1.4m*0.8m, weight 400kg, 200 tons about 500 bales. Depot size: length 36m*width 24m*height 6m. The depot is reserved for inlet and outlet channels, and can be stored in 2-3 layers of yard bundles

3、What is the density of yellow bamboo grass knots (40-50MM) (ask to Zhengda Tangjia), whether the capacity of 30-40m3/h of scraper loading machine can meet the processing needs of 12 tons / H.

According to the density of yellow bamboo grass knots to choose a more accurate model to meet the drying needs.

4, the drying heat source can use natural gas or electricity (many places in Chongqing can not use coal-fired or biomass), then the cost is how much respectively?

The cost of using natural gas is: 640.2 yuan per ton of drying cost, 302.36 yuan per ton of drying cost using coal

5、 How to calculate the volume of the drum 160m³? ¢2.8-28m (is the diameter of the cut surface 2.8M, if so the calculated volume is 246?)

Dryer volume: V1=Q1 /△TLn /K=5760042÷255÷140=161.3m³, take the dryer diameter 2800㎜, then the length L=161.3÷3.14×1.4×1.4=26.2m

6、 The quotation should include other related costs such as freight, and the turnkey project is adopted.

The itemized total amount includes installation and commissioning costs, excluding transportation costs.

7、 Is "Party B is responsible for guiding the installation" equal to "Party B is responsible for the installation".

Party B is responsible for the installation and commissioning training delivery

8, warranty time a production cycle is how long? One year or two years? The warranty period is one year and 12 months.

9、If coal is used as fuel, does the hot air furnace come with its own exhaust gas treatment equipment? How to meet the environmental requirements and meet the emission standards.

Equipped with 2 sets of boiler desulfurization and dust removal equipment to achieve environmental protection requirements

10、 What is the capacity of the power supply system? (transformer capacity)

Total power: 170.6 kW

11、 What is the floor plan of the drying plant? What is the size and layout of the wet grass room, drying workshop, hay room, fuel room, etc.?

Wet hay room can fit 2-3 transit vehicles for temporary storage of nine can, which is determined according to the volume of transit vehicles. Drying workshop: 90m*28m: height 8m, hay storage 8770㎡.

Finished pellets

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Online Inquiry