Alfalfa production enterprise is a shortcut

Time:

2023-01-03

The 2015 Central Document No. 1 clearly put forward: to accelerate the development of grass and pasture industry, support silage corn and alfalfa and other forage planting; carry out "grain to feed" and the pilot of the combination of breeding mode, and promote the coordinated development of grain, cash crops, forage triad planting structure; based on local resource advantages, vigorously cultivate special agriculture, and promote comprehensive agricultural Development layout adjustment.

In order to comprehensively promote the reform and development of grass-pastoral industry, according to the Ministry of Agriculture "on the issuance of <2015 grass-pastoral industry development pilot work program> notice" (agricultural pastoral grass ben letter [2015] No. 38) and "the General Office of the Ministry of Agriculture on the issuance of the 2015 grass-pastoral industry development pilot area list notice" (agricultural office pastoral [2015] No. 19) spirit, Xinjiang Department of Animal Husbandry identified Altai City as the whole region ( Hutubi County, Tacheng City, Altay City) to carry out the 2015 grass-pastoral development pilot counties (cities) one of the pilot work, combined with grain and grass pilot work, straw livestock demonstration, revitalization of the dairy industry alfalfa development action, silage corn promotion and other existing work base, grass-pastoral development pilot work, which is the opportunity to develop alfalfa grass industry in Altay City.

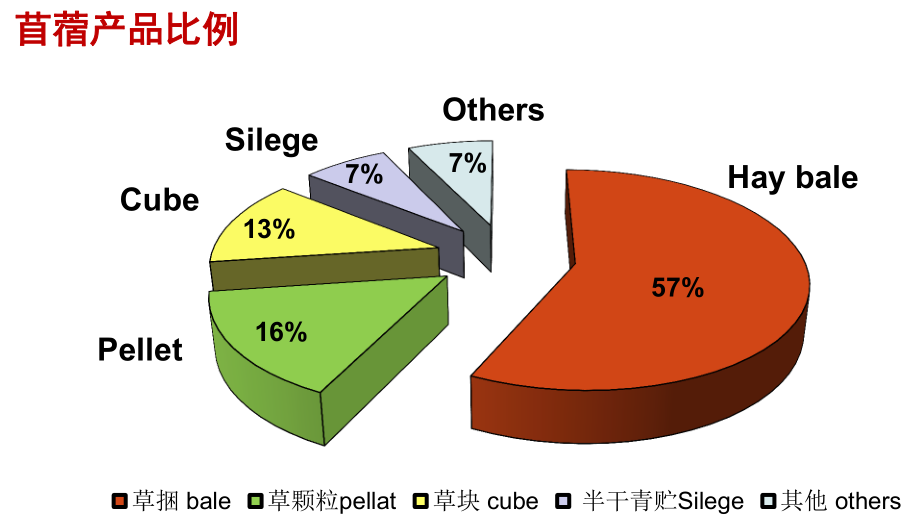

一(yī)、Domestic alfalfa grass status

After the melamine incident in 2008, with the restructuring of the dairy industry and dairy farming, and the emphasis on the quality of dairy farming, the demand for high quality forage grasses After the melamine incident in 2008, with the restructuring of the dairy and dairy farming industries and the emphasis on the quality of dairy farming, the demand for high quality forage grass has increased greatly and the grass industry has developed. At present, it is mainly distributed between 35°-43°N latitude, concentrated in Northwest, North China and Northeast China, etc. In 2014, the total amount of alfalfa products processed by enterprises was 1.41 million tons (excluding silage), accounting for 51.6% of the total amount of forage processed in China. Its products are mainly in the form of grass bales, grass blocks, grass pellets and grass meal, accounting for 72%, 22%, 12% and 44% respectively. However, there are not many large scale and strong enterprises in the grass industry, most of the small enterprises are selling grass products to nearby farms, even the larger grass enterprises have a sales radius of less than 200 km, mainly because of the high domestic transportation cost, which is 20-30% of the total price on average. Competition in the industry is obvious, but due to the significant drop in international shipping prices in recent years, the competitiveness of imported alfalfa and oats has been greatly enhanced, and with the obvious quality advantages of imported products, the number of imports has been increasing in recent years. 2014 national hay imports were 100.55 million tons, up 25% year-on-year. Among them, alfalfa hay imports amounted to 885,000 tons, accounting for 88% of total hay imports, up 16% year-on-year, with an average CIF price of US$ 387.24/ton. Mainly imported from the United States, Spain and Canada, of which 96.91% were imported from the United States. From the current industry situation, the price of domestic grass products is sold with reference to the price of international grass products down by a certain percentage, for example, the sales price of U.S. alfalfa products in the Chinese market in 2013 was about RMB 2,700, while domestic alfalfa products were below RMB 2,500. In terms of quality, the production process of products from countries such as the United States mostly uses drying technology, and the quality is more assured.

In 2014, the domestic production of alfalfa grass was close to 1.5 million tons, while the import volume reached 1 million tons. The supply of products cannot be guaranteed, and there will be a large gap in the supply of domestic alfalfa.

二、China's alfalfa market potential

(I) Market demand

In the future, the number of dairy cows in China is 9-14 million, based on 60% of lactating cows, lactating cows need 1 ton of alfalfa hay per year, and the market is expected to be 5-8 million tons/year. Breeding sow market demand, the number of breeding sows in China is about 50 million, each head needs 1.1-1.2 tons of compound feed per year, based on 10-15% additive ratio, it is expected to need 5.5-9 million tons of alfalfa pellets or grass meal. This is a potential market that will be gradually realized with the upgrade of industry development level.

(ii) Market changes

Due to the high competition in the globalized dairy industry and strict regulation of food safety, China's dairy farming industry has been forced to upgrade, with a shift from small community farming to standardized scale farming, faster integration, acquisition and trusteeship of small and medium scale dairy farms, increased standardized farming dairy farms and rapid increase in the use of alfalfa. Small and medium scale dairy farms were rapidly integrated, acquired and hosted in the industrial upgrade, forming a large group for standardized breeding, and the group's unified procurement and unified sales, causing the retail market to shrink.

The number of operating listed dairy farming groups increased, pulling the alfalfa market, industry self-discipline and integrity improved, and the structure gradually became reasonable.

Dairy groups that directly open letters of credit to import alfalfa are increasing, such as Modern Herding, Yili, Mengniu, Shanghai Bright Holstein, Dongying Aoya, New Hope, etc. The market space for traders and import agents becomes smaller.

Domestic alfalfa industry upgrading, integration of breeding and raising, building a whole industry chain community of interest, overseas investment in grass industry dairy groups to participate in sales and online sales will fundamentally affect the change of China's alfalfa market pattern, which is a "reshuffle" for both domestic and foreign grass industry companies.

Imported alfalfa and domestic alfalfa compete with each other and complement each other, forming different competitive situations in different areas, the market of high quality alfalfa still depends on imported alfalfa, among imported alfalfa American alfalfa still dominates, the brand will play an increasingly important role in future sales, and the awareness of establishing brand will be greatly improved

三、Experience and main problems of developing alfalfa grass industry in other regions of China

(a) Domestic regions with faster development of alfalfa grass industrialization include Dingxi, Baiyin and Jiuquan in Gansu and Alukeqin Banner in Inner Mongolia.

Gansu's experience is mainly to promote the construction of grass associations and the coordinated development of grass industry. The association plays the role of think tank and platform link, mainly responsible for one is to coordinate the work of grass industry enterprises, cooperatives and large planters in the region. Second is to strengthen the industry self-regulation management, improve the acquisition network, unified printing bills, assessment of grass planting area, cutting grass, grass collection and other specific business. Third, the development of industry standards, the implementation of quality and price. By the association to develop "alfalfa grass acquisition standards and prices", the implementation of the level of pricing, quality and price, unified purchase price. Fourth is to regulate the industry order, to create a good environment for industrial development. Five is to assist the government to implement the grass industry development planning. Implementation of industrial base construction, organization of enterprise visits, receive visits to attract investment, develop markets, help members sell products, reflect industry issues to the government, participate in policy formulation, etc.

Inner Mongolia Arukoqin Banner is known as the grass capital of China. At present there are 700,000 mu of alfalfa, and there are 2 million mu of planting potential in the surrounding areas. The main problems are: First, the quality of grass is unstable, the supply of first-grade grass exceeds the demand, the ratio of low-grade grass is large, and the quantity of first-grade or extra-grade alfalfa grass is seriously insufficient. Second, the sales market singles. Although some enterprises have established some cooperative relationships through their own sales channels, the limited supply capacity and single sales channel lead to low performance rate and poor ability of transferring surplus and deficit. Third, grass people and cattle people did not form an effective docking, resulting in the intermediate links seriously interfering with the market. Fourth, the grass industry association established a grass price release mechanism in early 2015, but due to the short time and narrow information collection channels and many other factors, resulting in little guidance for the sales market to draw on.

(II) Main problems of domestic alfalfa grass industry

The planting base land conditions and imported alfalfa varieties have poor cold resistance, lack of seedlings are common, weeds are many, the use of short years; mowing late, poor harvesting technology, natural drying protein loss, less leaf retention, frequent rain, mold and "tobacco" alfalfa.

Most of the domestic alfalfa is secondary and tertiary grass, RFV ≥ 130 alfalfa is good alfalfa, stable to ensure a certain number of RFV ≥ 150 alfalfa grass industry enterprises are not many. The quality between batches varies greatly and is unstable, and cows are stressed. Graded sales should be implemented to solve the problem of unstable quality.

Some enterprises are dishonest in sales, exaggerating the quantity and quality, resulting in failure to perform according to the contract, which affects the trust of dairy farms in domestic alfalfa. Dairy farms use "discolored glasses" to view domestic alfalfa, even if the enterprise produces special or super special alfalfa, still can not enjoy the reasonable price they deserve, hindering the technical progress of domestic enterprises to produce high-quality alfalfa grass and industrial upgrading.

四、Basic conditions for the development of alfalfa grass industry in Altai

Altay grass area is vast, which is the material basis for the development of animal husbandry and grass industry. The existing natural grass area is 147,636,000 mu, accounting for 14.2% of the total grass area of the whole territory and 83.4% of the total land area of the region, of which 108,589,500 mu is available for use.

In recent years, Altay has vigorously implemented the policy of "herding settlement" and developed a large amount of land. The land development of "640" tablelands in Altay will reach 300,000 mu, which is of great practical significance to guide farmers and herdsmen to plant alfalfa grass, cultivate grass industry base, build grass industry production and processing enterprises, develop and expand alfalfa grass industry economy, promote the development of animal husbandry and help farmers and herdsmen to get rich. At the same time, Altai as a traditional pastoral area, animal husbandry is one of the pillar industries, the development of grass industry will certainly promote the development of animal husbandry, grass industry and animal husbandry complement each other, therefore, around animal husbandry vigorously develop grass industry, for the economic development of Altai will undoubtedly play a huge role in promoting.

五、Opportunities for the development of alfalfa grass industry in Altai

Altai development of alfalfa grass industry to seize the opportunity to be identified by the Xinjiang Department of Animal Husbandry as one of the pilot counties (cities) of grass development experiments, drawing on the experience of other places, the development of planning, the establishment of parks, to create an industrial chain from planting base to production and processing, cultivate, grow alfalfa grass industry production and processing enterprises, and gradually build a high-quality base for the domestic alfalfa grass industry

(i) Create a national core base. The Ministry of Agriculture of the People's Republic of China has proposed a target of planting 6 million mu of commercial grass in the next 10 years, creating 5 - 6 core industrial bases in the north, 3 million tons of commercial hay, 2 million tons of alfalfa silage and 500,000 tons of grass pellets, and this overall plan is an important part of the construction of the national forage industry service system.

The national forage industry technology system is one of the 50 national modern agricultural industry technology systems of the Ministry of Agriculture, with a national forage industry research and development center, 6 functional research laboratories and 22 comprehensive experimental stations. Creating conditions to create a core industrial base will directly become a key technical support area for the national forage service system and become a key test area for national industrial policy.

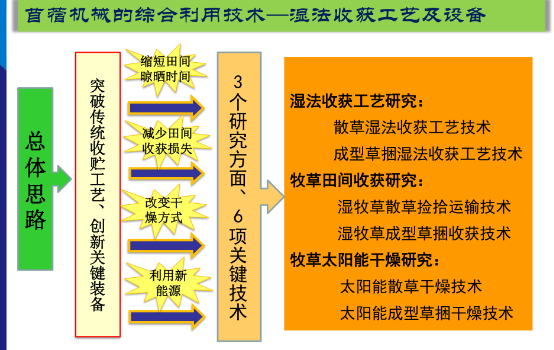

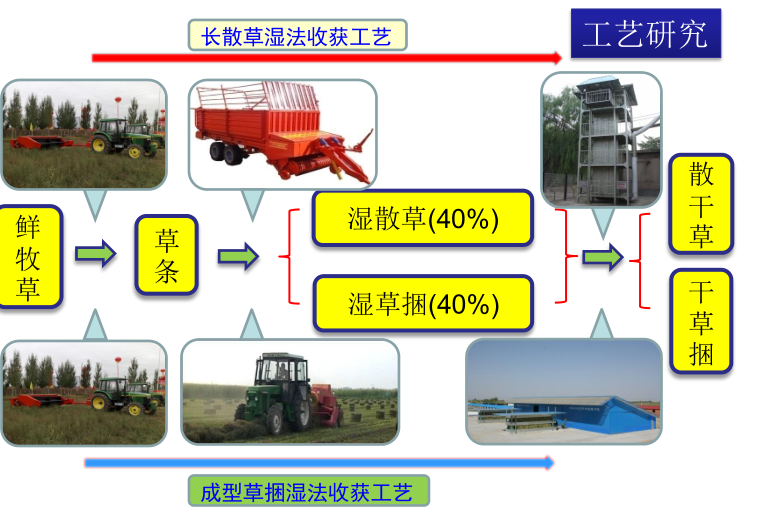

(II) alfalfa grass industrialization must alfalfa grass production and processing enterprise, the establishment of planting, harvesting to processing, production of the industrial chain, to fully promote the wet harvesting, wet drying process and equipment as the goal, to ensure the stability of quality.

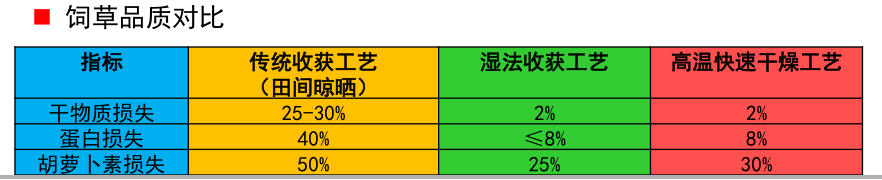

At present, the domestic alfalfa hay traditional harvesting process loss is serious. Forage dry matter loss of 15% to 30%, protein loss up to 40% of the total protein, carotene, vitamin C loss of 50%. If foreign wet grass baling and whole bale drying new technology is adopted, it can reduce the dry matter loss of forage by 10% to 25%, protein loss by 8%, and carotene and vitamin C loss by 25%.

(C) cultivate one of the leading enterprises in the alfalfa grass industry and form an industry association. Assist the government in implementing planning, training within the industry, promotion of new technologies, and industry self-regulation.

六、投資阿勒泰苜蓿草(cǎo)産業(yè)發展規劃

(I) Basic information of the company

Ltd. was founded in 1996, the company is located in Xiuwu County Industrial Zone, Henan Province, covering a total area of about 25,000 square meters, including a production area of about 14,000 square meters, the existing staff of more than 300 people, more than 50 professional and technical personnel of various types. We have passed "Swiss SGS quality certification", "German Rheinland BV certification", "EU CE safety certification" and "ISO9001-2008 quality certification". 2008 quality certification", is the China Manufacturing Network, Alibaba certified suppliers, is China Animal Husbandry Association director unit, China Biomass Energy Association member unit, China Grass Industry Association director unit, Henan Province Animal Husbandry Engineering Association director unit, Henan Province Agricultural Machinery Safety Research Association member unit, is Henan Province science and technology small and medium-sized enterprises, Henan Province feed pellet equipment research and development Center, the first batch of enterprises in Henan Province to obtain the electric business identity card.

Since its establishment, Hengmu Machinery has built 80 forage and straw pellet production lines at home and abroad, with an annual output of 300,000 tons of grass pellets. In Xinjiang, we have participated in more than 10 observation meetings above the prefecture and city level, built a complete set of production line of lemon pellets with an annual output of 20,000 tons in Inner Mongolia, and firstly developed and put into production a mobile truck grass pellet production line project in China. The forage pellets and straw biological equipment have been exported to more than 20 countries, influencing and profoundly changing the traditional local farming methods.

Since 2010, Hengmu machinery and Zhejiang University, Henan Agricultural University and other universities to carry out school-enterprise cooperation, dedicated to forage pellet sets of equipment and crop straw comprehensive utilization of complete sets of equipment research and development manufacturing. Among them, forage crushing, pellet equipment has 10 national patents, mixer, pellet machine 4 products enjoy national agricultural subsidies. Straw kneading machine, double rotor crusher, disc crusher and other host products and flat die pellet mill, vertical ring die pellet mill, ring die pellet mill three series of pellet mill products tend to mature, fully meet the various needs of different customers, research, production and marketing comprehensive level in the domestic leading position.

Ltd. is our partner, located in Salhusong Township, Altay City, was founded in September 2014, registered capital of 500,000 yuan, a total investment of more than 5 million yuan, a total area of more than 40,000 square meters, construction area of more than 15,000 square meters, the company's existing staff of 22 people, the follow-up full standard of more than 50 people, two senior professional engineers, two general technicians The company has more than 30 ethnic workers. Lijia straw feed company is to crop straw pellet feed processing and sales, accompanied by Lijia breeding cooperative integrated enterprise, with an annual production capacity of 30,000 tons. Lijia straw feed company was built and put into operation, a comprehensive change in the breeding structure of farmers, reduce the previous loss in the forage storage process, improve the economic benefits of farmers, drive the region's farmers to change their minds, from the traditional mode of rough to scientific breeding mode, so as to achieve the smooth implementation of herding settlement, shed feeding, pasture protection, etc., to lay a solid foundation for the modernization of scientific breeding in our region. foundation.

(II) Investment Planning

We understand that Altai has the basic conditions suitable for producing high quality alfalfa grass and is one of the famous pasture areas in China. At the same time, the government is also building a base of 100,000 mu. As the earliest enterprise that manufactures complete sets of equipment for grass industry in China, we agreed with Lijia Feed Company to build a "one-stop" industry chain from alfalfa planting to production and processing by taking advantage of our own manufacturing equipment and production, processing and sales of straw feed and concentrate feed, and by focusing on the development plan of grass industry of Altai government. "The company will cultivate, build and develop alfalfa grass industry, help farmers and herdsmen to increase their income and get rich, promote the development of animal husbandry in Altai and promote the economic construction of Altai.

1, total investment planning (2016 - 2026), investment scale 150 million yuan.

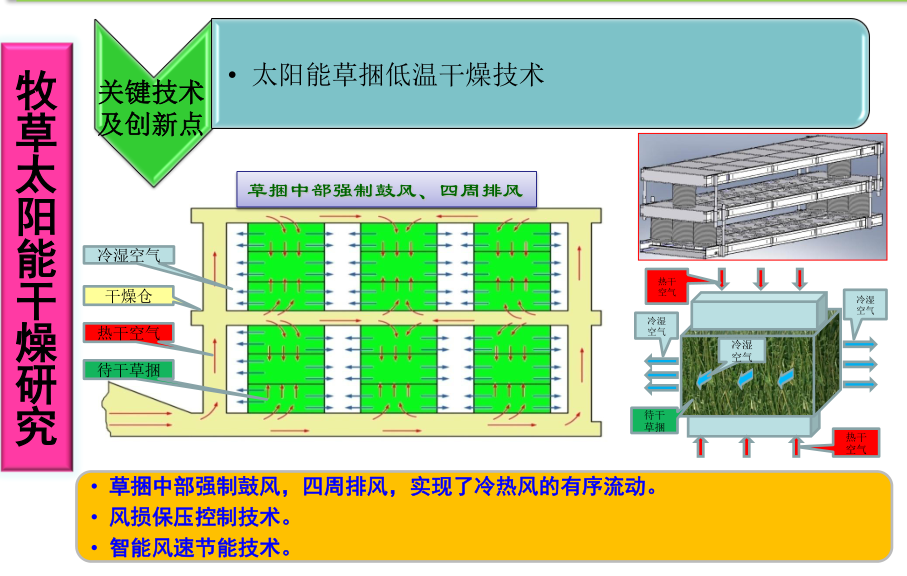

Investment of 20 million to build an annual output of 90,000 tons of solar-powered grass bale low-temperature drying production line; investment of 20 million to build an annual output of 90,000 tons of loose grass picking and transporting high-temperature rapid drying production line; investment of 15 million to build an annual output of 90,000 tons of grass block processing production line; investment of 30 million to build an annual output of 60,000 tons of grass pellet production line; investment of 15 million to build an annual output of 30,000 tons of alfalfa grass semi-dry silage wrapping production line; investment of 10 million to build annual output of 30,000 tons of alfalfa grass full price with feed production line; investment of 10 million to set up alfalfa grass harvesting machinery operation team; plant, alfalfa grass base construction 30 million yuan.

2、Phased investment planning

2016 --- 2018, complete the first phase of construction. Including 30,000 tons of solar-powered grass bale low-temperature drying production line; 10,000 tons of grass pellet production line; invest 10 million to set up alfalfa grass harvesting machinery operation team; plant, alfalfa grass base construction 30 million yuan.

2019 --- 2023, complete the second phase of construction. Including 60,000 tons of solar-powered grass bale low-temperature drying production line; 90,000 tons of bulk grass picking and transporting high-temperature fast drying production line; 90,000 tons of grass block processing production line; perfect alfalfa grass harvesting machinery operation team, as well as plant and alfalfa grass base supporting construction.

In 2024---2026, complete the three phases of construction. Including 50,000 tons of grass pellet production line; 30,000 tons of alfalfa grass semi-dry silage wrapping production line; 30,000 tons of alfalfa grass full-price with feed production line; fully complete the alfalfa grass harvesting machinery operation team, as well as the plant, alfalfa grass base supporting construction.

3、After the investment is completed, it will form an annual production and processing capacity of nearly 400,000 tons of alfalfa grass, and initially realize the development goal of grass industry in Altai.

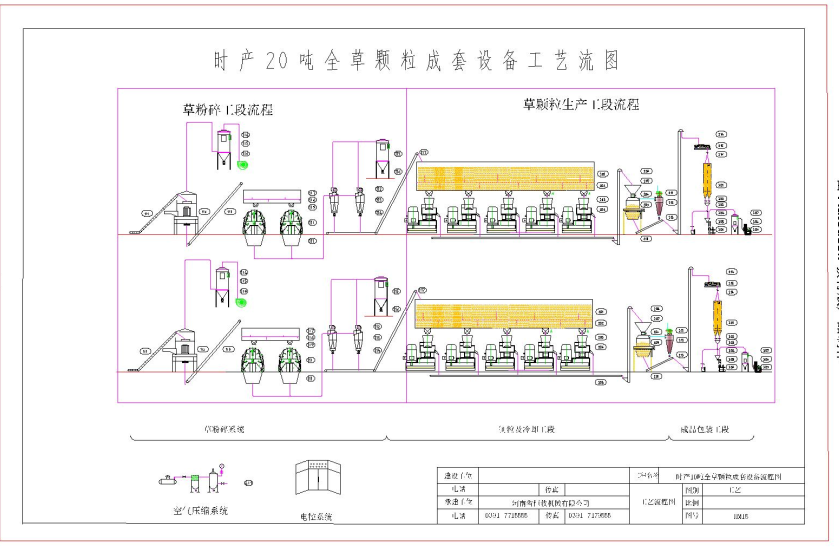

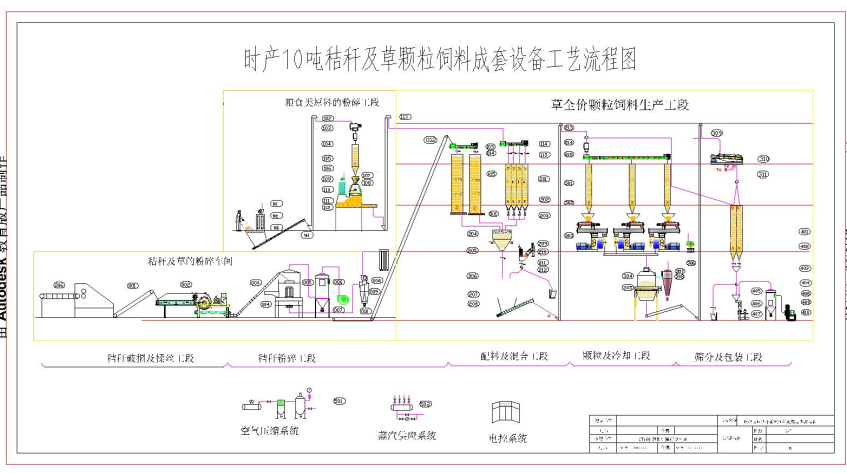

(C) Production process technology program

1、Forage semi-dry silage process

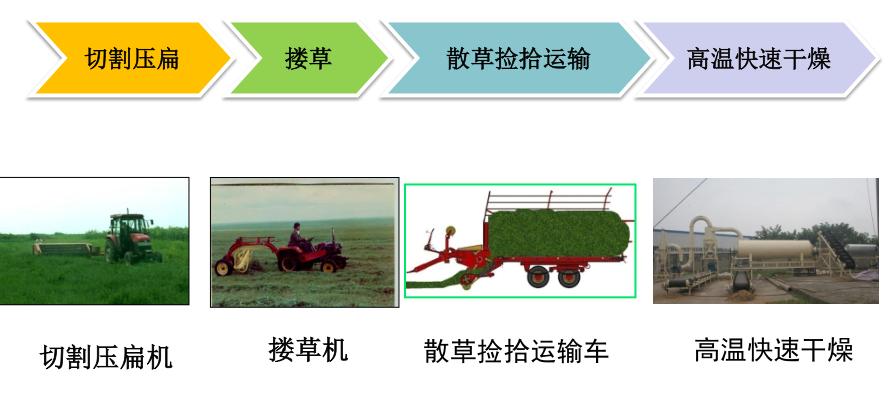

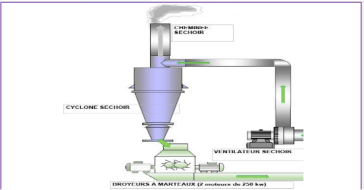

2、High temperature and rapid drying process of forage grass bulk grass

3、Forage bale low temperature drying process

4、Alfalfa grass briquetting process

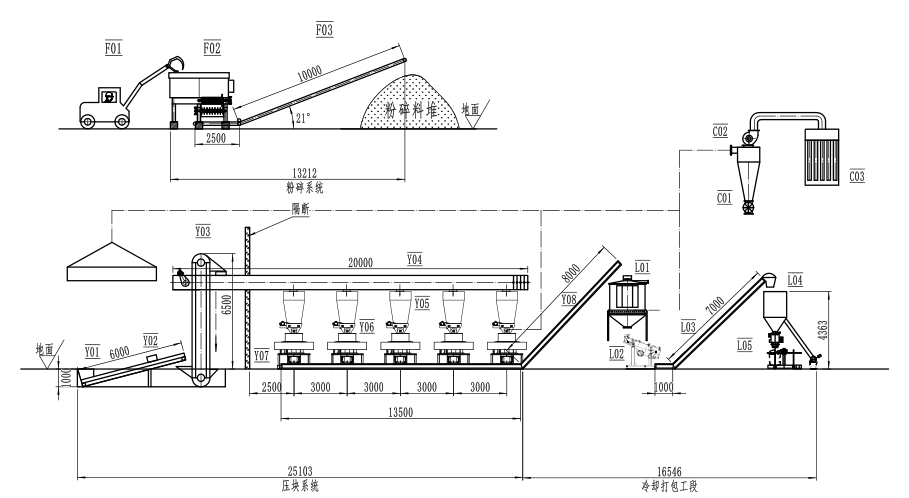

5、Alfalfa grass pellet process

6、Alfalfa grass full price pellet feed process

7、Description of grass pellet production process

Wet high temperature drying of alfalfa grass

低(dī)溫幹燥

Grass Powder Production

原料選擇 選擇顔色青綠或黃綠,具有草(cǎo)香味,品質優的青幹草(cǎo)作為(wèi)草(cǎo)粉加工(gōng)原料,杜絕發黴、變質幹草(cǎo)進入加工(gōng)程序。

草(cǎo)粉加工(gōng) 首先通(tōng)過破捆機(jī)把草(cǎo)捆破碎到(dào)松散狀态,然後通(tōng)過粉碎機(jī)粉碎到(dào)适合動物(wù)需要的長(cháng)度,具體操作見(jiàn)各粉碎機(jī)說明。

草(cǎo)粉貯藏 草(cǎo)粉加工(gōng)後,定量分裝,運輸堆放(fàng)在幹燥的地方備用。

配料準備

按複合草(cǎo)顆粒單位生(shēng)産量準備草(cǎo)粉、亞麻餅、能(néng)量蛋白(bái)合劑、磷酸氫鈣、人工(gōng)鹽、畜禽用複合添加劑等。

Grass pellet processing

1. Grass pellet processing equipment

The main equipment for processing grass pellets is a pellet mill or pellet set. Small-scale production usually only use the pellet mill single machine for pelleting. Large-scale, commercial grass pellet production is more often used by the pellet mill and a variety of ancillary equipment unit. The pellet size is from 6mm to 16mm in diameter, and the general pellet capacity is from 550kg/m3 to 600kg/m3.

The vertical ring die pellet mill is generally composed of four parts: mixing, pellet pressing, transmission and frame, and its main technical indicators are as follows.

Working speed: 40 rpm~50 rpm

Sieve aperture: 5mm 8mm, 6mm, 10mm

Can be pressed grass powder fineness: not more than 5=10mm

Pellet cooling method: natural cooling type

2. Grass pellet processing process

The whole grass pellet is a kind of raw material, no need of ingredients, if the production of full-price grass pellet needs ingredients and mixing section, the formula design is according to the nutritional requirements of various livestock and poultry, the preparation of grass pellets containing different nutrients.

Mixing of raw materials According to the requirements of grass pellet formula design, various ingredients are pre-mixed with a small amount of grass powder in proportion to the unit output, and then all grass powder is added and mixed to enter the next processing procedure. The raw materials are weighed accurately before mixing, and the small amount of ingredients must be premixed.

Grass pellet forming The evenly mixed raw materials enter the grass pellet forming machine to extrude and form, and the broken and scattered parts are returned to the cage for reprocessing, and the formed pellets enter the cooling device for heat dissipation. Due to the low water content, it is suitable for long-term storage without mold and deterioration.

Grass pellets are cooled. The formed pellets enter the cooling device to dissipate heat and then are sent to the finished product outlet.

Grass pellets are packed and stored. The finished grass pellets are packed quantitatively at the outlet, sealed and then sent to the warehouse for storage.

3. Grass pellets product logo, packaging, transportation, storage

Product packaging should be clear and firm label, the content of the label should comply with the provisions of GB10648-1999.

Grass granules products should be packed in impermeable plastic woven bags, the weight deviation should not exceed 0.5% of the net weight.

The products should be protected from rain, moisture, fire and pollution during transportation.

When the products are stored, they should not be directly on the ground, it is better to pad a wooden shelf underneath, and they should be stacked neatly, and the ventilation channel should be left at 3m interval. The pile should not be too high, the distance from the top of the shed is not less than 50cm. open-air storage should have rainproof facilities, and the rainproof cloth should be uncovered to dry in sunny weather.

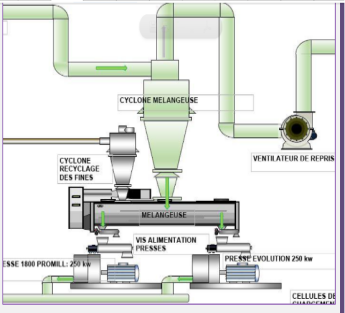

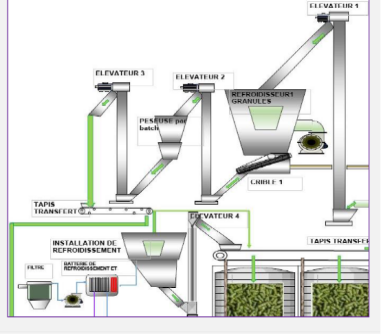

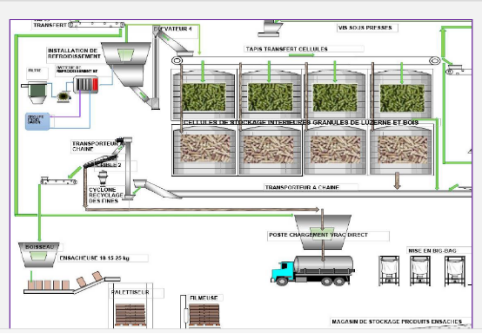

Production Processes

1. The bales enter the bale breaker through the belt conveyor, and then enter the first pulverizer through the mesh chain conveyor to crush into coarse powder; or enter the disc combination pulverizer to crush directly.

2. Then enter into the second pulverizer through the scraper, and crush into fine powder;

3. After the elevator into the mixer, mixed evenly into the silo;

4. Through the dialer into the first strand of the granulator cage, through the high temperature fumigation and start granulation;

5. After the granule is discharged, it enters the cooler through the U-shaped scraper conveyor;

6. After the pellets are cooled, they will enter the vibrating screen by the U-shaped scraper and the elevator;

7. After vibrating and screening, it enters into the finished pellet bin;

8. The finished pellets are packed into bags through the automatic baler.

Equipment Solutions

This project adopts the complete set of equipment produced by today's world vertical ring die pellet machine XGJ550 pellet production technology, the power transmission of this equipment adopts chain transmission, energy saving 24%, through the centrifugal wind dust removal and grid magnetic dust removal, after two dust removal workshop dust emissions meet national requirements. The pellet forming adopts mold high pressure forming, with the advantages of good particle length and not easy to break.

Needed basic conditions of the project

1、Layout idea of alfalfa grass processing products

In order to ensure that the 100,000 mu of alfalfa products in Altai City are all high quality alfalfa grass, according to the design idea of 70% of alfalfa grass wet grass dried and processed for sale in other markets, and 30% of semi-silage wrapped for sale in the vicinity. 100,000 mu of alfalfa planting area, 3500-4000 kg of fresh alfalfa harvested per mu per year, and 3 crops of alfalfa harvested per year. First flowering harvest time 7-10 days, the first flowering harvest contains about 77.5% moisture, hay generally contains 15%-18% water, usually 3.71 kg of fresh grass sun-dried 1 kg of hay, each crop can be harvested 116,600 tons of fresh alfalfa - 133,300 tons. Among them, 81620 tons-93310 tons of wet grass drying and 34,980 tons-39990 tons of semi-silage wrapping.

The design capacity of room temperature and solar drying equipment is 780,000 tons, requiring 400 tons of raw materials per hour, processing 9600 tons per day, with a production period of 10-15 days per harvest, processing 96,000 tons-144000 tons in total. The processed hay is 22,000 - 25,150 tons. The design capacity of alfalfa grass semi-dry silage wrapping production line is 270,000 tons, 150 tons per hour, 3,600 tons per day, production period 10-12 days, total processing 36,000-43,200 tons. After drying, 50% of alfalfa grass is dried in blocks and 50% is made into pellets. The output of briquetting is 11,000-12,575 tons, and 11,000-12,575 tons of alfalfa grass pellets.

Being prepared in the field requires 6-7 kg of diesel fuel (containing 210 million joules of energy) per ton of hay, and contains 18.9 billion joules per ton of hay, i.e. 60-70 joules of feed energy for every joule of liquid fuel consumed. Drying chopped hay with high-temperature dryers requires 210-250 kg of diesel fuel and 150 kW/h of electricity (about 11.7 billion joules) per ton of product, i.e., only 1.6 joules of feed energy can be obtained for every joule of fuel consumed. Using modern technology to process green fodder into block and pellet feed, the highest yield harvest rate per unit area is about 90%.

2、Guarantee of raw materials

The first flowering period of alfalfa grass 7-10 days is the most suitable time for harvesting. To ensure high quality alfalfa grass products, rapid drying is required, and the drying time is only 10-15 days, which requires sufficient control ability of raw material base. To ensure the efficient operation of the project, we suggest that the company itself must have core raw material base, and the quantity cannot be less than 50% of the production capacity, i.e. 50,000 tons of self-provided alfalfa grass base.

3、Guarantee of basic conditions

According to the current design plan, the 6 production lines need land of 200 mu, and we suggest that the market needs to cover an area of 300 mu, and needs electricity of 5000-8000 kW per hour and water of 30 tons per hour. The infrastructure should be realized with 5 passages and 1 level. The management function of grass industry association should be given to regulate the local grass growers and grass market order. There should be a special docking department, including administration, funds, taxation and other aspects of policy inclination.

Henan Province Hengmu Machinery Co.

November 2015

Annex: Alfalfa Industry Policy

● 2013 .7 - Ren Jizhou and 9 other academicians

"Suggestions that China's 'arable agriculture' should be shifted to a 'grain and grass balanced structure' type"

● 2014.4--Democratic League Central Committee

"Suggestions on Accelerating Integrated Development of Agriculture and Animal Husbandry in Western Arid Regions to Improve Food Security Assurance"

● 2014 - Academician Fang Jingyun, Chinese Academy of Sciences, et al.

Ecological grass special zone: the road to reform and development of pastoral areas in China

● 2014.9 - Chinese Academy of Agricultural Sciences

Strategic Suggestions for Developing Pasture Industry to Ensure National Food Security

● 2014.9--Chinese Ministry of Agriculture

Suggestions on Grassland Protection and Construction and Grassland Animal Husbandry Development in Pastoral Areas

2014.10 - Vice Premier Wang Yang of the State Council

Zhongnanhai Grassland Industry Development Symposium

● 2015.5 - Ministry of Agriculture of China

Guidance of the Ministry of Agriculture on Promoting the Accelerated Development of Grass-fed Animal Husbandry

(Agriculture and Animal Husbandry Development [2015] No. 7)

Finished pellets

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Online Inquiry