Annual output of 90,000 tons of bio-organic fertilizer project using straw

Time:

2023-01-03

Project name: Ninety thousand tons of bio-organic fertilizer project per year using straw

1.Project Overview

1.1 Contractor Profile

***In order to promote the development of ecological agriculture, the formation of: "bio-organic fertilizer - pollution-free, green, organic base - pollution-free, green, organic agricultural products - pollution-free, green, organic meat (food) - livestock and poultry (agricultural products processing) waste - bio-organic fertilizer". Green ecological agriculture cycle industry chain, to achieve agricultural efficiency, farmers increase income. The company uses pig manure to produce biogas, digestate and biomass straw to produce organic fertilizer, organic fertilizer to promote efficient organic agriculture as a whole, into a virtuous cycle of development.

The company was founded in 1997, under the *** City *** Office, in 2006, the shareholding system transformation, the existing fixed assets of 10,000 yuan, the company's existing staff, including technical personnel, covers an area of 10,000 acres, the company has a farm around the annual stock of live pigs, the annual slaughter head, the current plan relying on the York boar head, Duroc boar head, long white sow head, stocking head, slaughter head lean meat type The manure of commercial pigs is used as raw material to produce biogas, and the mixture of digestate and biological straw has an annual output of 90,000 tons of organic fertilizer production line. While developing itself, the company drives many farmers around to develop breeding with technology and service, cultivates breeding communities and drives many farmers. At present, the company has transferred a certain number of acres of land, driving a certain number of farmers to plant corn and other crops and deep processing, and has a strong radiation drive.

The company is now a leading enterprise in *** City, *** Province pollution-free livestock products production base, the year *** City People's Government awarded the standardized breeding plots, the year was named by the *** Provincial Association for Science and Technology as a popular science base, the year was awarded by the *** City People's Government as an advanced unit, the year was awarded by the *** City People's Government standardized breeding plots, the general manager *** was named the first batch of outstanding rural practical talents, *** City The fourth CPPCC member.

1.2 The need for project construction

In order to promote the comprehensive utilization of crop straw, to ensure the completion of the "Twelfth Five-Year Plan" (hereinafter referred to as "the Plan") proposed "by 2015 the province's comprehensive utilization rate of straw more than 85%" goal, in accordance with the "National Development and Reform Commission, the Ministry of Agriculture on the in-depth promotion of air pollution prevention and control of key areas and the main grain and cotton production areas of the comprehensive utilization of straw notice (Development and Reform of environmental resources [2014] No. 116) spirit, *** Provincial Development and Reform Commission in conjunction with *** Provincial Department of Agriculture to develop a "*** Province 2014-2015 crop straw comprehensive utilization of the implementation plan.

***As a national important agricultural province and the first major grain production province, the total amount of straw resources is abundant. According to preliminary statistics, in 2013 the province's wheat, corn, rice, cotton, peanuts and other crop straw theoretical production of 88.5 million tons, can be collected 79.5 million tons, accounting for more than 10% of the country's total straw resources can be collected. From the distribution of straw resources in the province, **, *** straw production reached more than 10 million tons, *** straw resources totaling more than 5 million tons, seven provincial cities straw production accounted for more than 65% of the province's total. The province's straw varieties to wheat and corn straw, accounting for more than 70% of the total straw.

Preliminary statistics, in 2013 the province's comprehensive use of crop straw 50 million tons, the comprehensive utilization rate of 50%. Among them, through mechanical crushing and return to the field, the production of organic fertilizer, straw fertilizer utilization amounted to 30 million tons, accounting for 40% of the total use of straw, equivalent to reducing the amount of fertilizer more than 1 million tons, saving farmers' expenses 2.5 billion yuan, *** province straw comprehensive utilization pace gradually accelerated. However, there are also problems such as: low degree of straw commercialization, low level of comprehensive utilization; low degree of industrialization of straw comprehensive utilization, straw comprehensive utilization enterprises generally have a low level of technology, small scale of production, poor economic efficiency, etc.

Straw is an important material basis for the development of modern agriculture. Straw is rich in organic matter, nitrogen, phosphorus, potassium and trace elements, is an important source of organic fertilizer for agricultural production. Practice has proved that the scientific and reasonable application of organic fertilizer can not only provide rich nutrients for crops, improve the appearance of crop quality and internal quality, help reduce production costs, improve the competitiveness of agricultural products, but also in improving soil, fertilization, improve the overall production capacity of agriculture, to maintain arable land "land power always new" has an irreplaceable role The role of conservation tillage is irreplaceable. Continue to promote the popularization of conservation tillage technology, by encouraging enterprises to use straw to produce organic fertilizer, etc., can effectively improve the utilization rate of straw fertilizer. At the same time, vigorously develop the use of organic fertilizer, is the inevitable requirement for sustainable development of agriculture, is conducive to improving the production level of green and pollution-free agricultural products. Therefore, the construction of the project is very necessary.

1.3Project construction plan and scale

The project uses straw, livestock manure and other agricultural waste, using high-temperature composting and fermentation technology to build an annual output of 90,000 tons of organic fertilizer project. The main construction is fermentation workshop, drying workshop, finished product storage and related supporting facilities and other buildings. The total area is 8650 square meters, and the construction area is 8150 square meters. There are 58 sets of new production equipment such as fermentation tanks and crushers.

After the project is completed, the annual output of organic fertilizer will be 90,000 tons, part of which will be used in the existing 40,000 mu planting base of the enterprise, and the other part will be used by the surrounding farmers and enterprises at cost price as agreed with the local government.

1.4 Product Standards

Quality standards for the production of organic fertilizer products to implement the national standards of the People's Republic of China and the Ministry of Agriculture organic fertilizer product standards (NY525-2011).

Chapter 1 Project background and construction necessity

1.1 Project Background

In order to promote the comprehensive utilization of crop straw, to ensure the completion of the "Twelfth Five-Year Plan" (hereinafter referred to as "the Plan") proposed "by 2015 the province's comprehensive utilization rate of straw more than 85%" goal, in accordance with the "National Development and Reform Commission, the Ministry of Agriculture on the in-depth promotion of air pollution prevention and control of key areas and the main grain and cotton production areas of the comprehensive utilization of straw notice (Development and Reform of environmental resources [2014] No. 116) spirit, *** Provincial Development and Reform Commission in conjunction with *** Provincial Department of Agriculture to develop a "*** Province 2014-2015 crop straw comprehensive utilization of the implementation plan.

***As a national important agricultural province and the first major grain production province, the total amount of straw resources is abundant. According to preliminary statistics, in 2013 the province's wheat, corn, rice, cotton, peanuts and other crop straw theoretical production of 88.5 million tons, can be collected 79.5 million tons, accounting for more than 10% of the country's total straw resources can be collected. From the distribution of straw resources in the province, **, *** straw production reached more than 10 million tons, *** city straw resources totaling more than 5 million tons, seven provincial cities straw production accounted for more than 65% of the province's total. The province's straw varieties to wheat, corn straw, accounting for more than 70% of the total straw.

Preliminary statistics, in 2013 the province's comprehensive use of crop straw 64 million tons, the comprehensive utilization rate of 80%. Among them, through mechanical crushing and return to the field, the production of organic fertilizer, straw fertilizer utilization amounted to 30 million tons, accounting for 48% of the total use of straw, equivalent to reducing the amount of fertilizer more than 1 million tons, saving farmers' expenses 2.5 billion yuan, *** province straw comprehensive utilization of the pace gradually accelerated. However, there are also problems such as: low degree of straw commercialization, comprehensive utilization of low level; straw comprehensive utilization of low degree of industrialization, straw comprehensive utilization of enterprises generally have a low level of technology, small-scale production, poor economic benefits.

At present, soil fertility is an important basis for determining the production capacity of arable land, and is an important condition for high and stable crop yields and sustainable development. However, in the past 20 years, China's fertilizer use "triple three light" (heavy chemical fertilizer, light organic fertilizer; heavy nitrogen fertilizer, light phosphorus and potassium fertilizer; heavy large amount of elements, light trace elements) phenomenon is increasingly serious, fertilizer application ratio is seriously out of balance, the proportion of organic fertilizer input has dropped from 60% in the 1980s to 40% in the 1990s This has led to an obvious decline in the quality of arable land. According to the data analysis of 90 soil nutrient monitoring points and survey points of the Ministry of Agriculture, the soil organic matter content of arable land nationwide is low, only 18% on average, and only about 1% in dry land, with a large gap between the ground strength level of developed countries such as Europe and the United States. The decrease of organic fertilizer input is one of the main reasons for the decrease of soil fertility. The reduction of soil fertility will be detrimental to the sustainable development of agriculture. Therefore, it is important to vigorously develop organic fertilizer to promote the sustainable development of Chinese agriculture. Crop straw and other agricultural wastes are important biomass resources, containing a variety of effective components that can be used, in addition to the vast majority of carbon, but also contains potassium, silicon, nitrogen, calcium, magnesium, phosphorus and other elements and minerals, hemicellulose, lignin, protein, amino acids and other organic matter components. Reasonable crop straw fertilizer, in promoting agricultural development, prosperous rural economy, increase farmers' income there is a huge potential.

*** City straw generation type to wheat, corn straw, mainly from the distribution of straw resources in the province, the local straw resources are the most abundant, straw production reached more than 10 million tons, its production accounted for more than 12% of the province's share; straw utilization rate of only 63.52%, the utilization level is not high. This project is aimed at the current local crop straw processing difficulties, using high-temperature composting technology to produce organic fertilizer, which can effectively reduce the environmental pollution caused by straw burning and indiscriminate discharge of agricultural waste, realize the recycling of resources, and improve the comprehensive utilization rate of local straw resources. The project is proposed in such a context.

1.2 Project construction necessity

1.2.1 The construction of this project is an important way to realize the fertilization of crop straw

Straw is an important material basis for the development of modern agriculture. Straw is rich in organic matter, nitrogen, phosphorus, potassium and trace elements, and is an important source of organic fertilizer for agricultural production. Practice has proved that the scientific and reasonable application of organic fertilizer can not only provide rich nutrients for crops, improve the appearance and quality of crops, help reduce production costs, improve the competitiveness of agricultural products, but also in improving soil, fertilization, improve the comprehensive production capacity of agriculture, to maintain arable land "land power always new" has an irreplaceable role The role of conservation tillage is irreplaceable. Continue to promote the popularization of conservation tillage technology, by encouraging enterprises to use straw to produce organic fertilizer, etc., can be an effective way to improve the utilization rate of straw fertilizer.

1.2.2 The construction of this project is a necessary requirement for the sustainable development of agriculture

The long-term application of organic fertilizers and the combination of land use and land nourishment are the fundamental reasons why traditional Chinese agriculture has flourished for 5,000 years. The inspiration from this is that the sustainable development of agriculture must be based on the sustainable development of land fertility. Practice has proved that the application of organic fertilizer is an effective measure to fertilize the soil and improve soil strength, because organic fertilizer has the following very important role: ① organic fertilizer fertilizer effect is long-lasting, comprehensive nutrient elements, can meet the crop growth of macronutrients and trace elements, increase the soil organic matter content, promote the formation of soil grain structure, enhance soil water retention, fertilizer and aeration capacity; ② can promote soil microbial reproduction, increase the type and number of microorganisms in the soil. Increase the type and number of microorganisms in the soil, thus accelerating the decomposition and accumulation of nutrients in the soil; ③ can activate soil nutrients, increase and renew the soil organic matter, combine with fixing the active ingredients of fast-acting chemical fertilizers, improve the utilization rate of chemical fertilizers, reduce the leaching loss of chemical fertilizers, avoid pollution of the environment and protect the ecology; activate the metabolism of microorganisms in the soil to degrade the toxic substances in the soil and maintain the vitality of the soil ;④ organic fertilizer and chemical fertilizer with the application, not only can improve the yield and quality of crops, but also can improve the utilization rate of nutrients of fertilizers (organic and inorganic fertilizers).

With the rise and development of petroleum agriculture, China began to produce and use inorganic chemical fertilizers in large quantities. Chemical fertilizers not only improve crop yields and increase agricultural efficiency, but also have the advantages of high fertilizer efficiency, fast results, convenient transportation and use, labor and time saving. This has promoted the massive use of chemical fertilizers. Chemical fertilizers have played an indelible and important contribution in promoting the development of Chinese agriculture. However, long-term single application and partial application of chemical fertilizer will damage the soil granular structure, resulting in soil consolidation, so that the soil organic matter content is reduced, water retention, fertilizer, aeration performance is reduced; at the same time will also make the soil microbial population of a single, the number of reduced, the ground force is reduced; if you do not insist on chemical fertilizer and organic fertilizer with the application, then you can not make the application of chemical fertilizer in the soil combined with fixed, most of the active ingredients will be leached loss, both Reduce the utilization rate of chemical fertilizers, but also pollution of the environment; In addition, unreasonable fertilization will also cause a decline in the quality of agricultural products, as manifested in the melon and fruit is not sweet, rice and vegetables are not fragrant, the rise of harmful nitrate content in food, endangering human health. These problems have attracted the high attention of the international community. The United States and Europe and other developed countries have sprung up organic agriculture production, began to vigorously promote the use of soil preservation, fertilization, non-polluting new organic fertilizers, to limit the use of chemical fertilizers. Vigorous development and use of organic fertilizers is an inevitable requirement for the sustainable development of agriculture.

1.2.3 The construction of this project is an important measure to realize the development of organic fertilizer industrialization

Organic fertilizer industrialization, is market-oriented, to improve the economic and ecological benefits as the center, the implementation of organic fertilizer specialized production, social services, enterprise management, production, supply, marketing, trade, industry, agriculture, closely integrated to form a "one-stop" production and management of commercial organic fertilizer mechanism. Commercial organic fertilizer production and management is the core of organic fertilizer industrialization. The so-called commercial organic fertilizer, is the organic waste (including traditional organic fertilizer, including organic fertilizer raw materials) concentrated factory processing, through high-temperature fermentation, the elimination of viruses, germs, and through drying into granules to produce organic fertilizer, add part of the chemical fertilizer, the production of organic inorganic compound fertilizer, packaged into bags, can be used locally, can also be stored for a longer period of time, long-distance transport, as a commodity into the market of New organic fertilizer.

1.2.4 The construction of this project will help reduce the impact of agricultural waste on the environment

Increase the amount of organic fertilizer and bio-organic fertilizer application, reasonably reduce the amount of chemical fertilizer, and accelerate the harmless and resourceful use of agricultural organic waste has become the mainstream and direction of agricultural production in the 21st century. Organic waste is divided into four categories: primary production waste (such as crop straw, dead branches and leaves, etc.), secondary production waste (such as livestock and poultry manure, etc.), organic waste from industrial and sideline industries (such as agricultural and livestock products processing waste) and human waste (such as household garbage, human waste and urine, etc.). China's organic waste production ranks among the world's leading, including the annual output of crop straw more than 500 billion kilograms, 134 billion kilograms of livestock and poultry manure emissions, more than 70 billion kilograms of municipal waste. With the rapid development of industrial and agricultural production and the increase in population, organic waste will increase at an average annual rate of 5% to 10%. These organic wastes, especially the large and medium-sized urban garbage and suburban livestock manure has become a major source of environmental pollution. If these organic wastes are resourceful and reused to produce organic fertilizer, it is important to save natural resources, prevent environmental pollution and realize the virtuous cycle of ecological economy.

1.2.5 The construction of this project is conducive to improving the production level of green and pollution-free agricultural products

Conventional modern agriculture has reduced the quality of agroecological environment and food safety due to excessive or unreasonable application of some chemical synthetic substances in the production process. Since the 1990s, with the development of economy and society and the improvement of living standard of urban and rural residents, people have higher and higher requirements for ecological environment quality and food quality and safety, which provides a broad market for the development of ecological agriculture and green food. With the development of eco-agriculture and organic agriculture, the market share of green food and organic food will increase significantly. In terms of technical requirements, the production of green food is prohibited or restricted to chemical fertilizers, mainly using organic fertilizers, biogas fertilizers, biological fertilizers, green manure, cake fertilizers, etc., which have been sterilized and decomposed by high-temperature fermentation; in comparison, the production of organic food has more stringent requirements for fertilizers, and the use of chemical fertilizers is strictly prohibited. Therefore, the production of green food and organic food can not be separated from the harmless organic fertilizers. Industrial development of new harmless organic fertilizers will provide an important source of organic fertilizer for the development of green food and organic food production, and promote the development of green food and organic food.

Chapter 2 Resource Conditions and Market Analysis

2.1Analysis of resource conditions

***位于***市(shì)***辦事(shì)處***村(cūn)。目前擁有年(nián)出欄能(néng)力10萬頭生(shēng)豬的養殖規模。目前采用幹清糞的廢污處理工(gōng)藝,日産鮮糞125噸,污水(shuǐ)900m³。其中鮮糞中幹物(wù)質含量約18-20%,污水(shuǐ)中總固體濃度約0.6-1.0%,COD約8000-15000mg/L,BOD5約5000-6000mg/L,懸浮物(wù)4000-5000mg/L,pH 6.5-6.8。

***市(shì)稭稈産生(shēng)類型以小(xiǎo)麥、玉米稭稈為(wèi)主,從(cóng)全省稭稈資源分布看(kàn),當地稭稈資源最為(wèi)豐富,稭稈産生(shēng)量達到(dào)1000萬噸以上(shàng),其産生(shēng)量占全省的比重都在12%以上(shàng);稭稈利用率僅為(wèi)63.52%,利用水(shuǐ)平不高(gāo)。

此外,企業(yè)采用“公司+基地+農戶”的運營模式,現有種植基地4萬畝,按照(zhào)每畝種植基地年(nián)容納有機(jī)肥按1噸預計,年(nián)可消耗生(shēng)物(wù)有機(jī)肥4萬噸。剩餘部分用于周邊其他農戶使用。

從(cóng)資源條件(jiàn)分析來看(kàn),項目單位有穩定的原料來源,有足夠的耕地容納有機(jī)肥,剩餘部分供周邊農戶及種植企業(yè)使用,具備産品消化條件(jiàn)。

2.2 Market Analysis

2.2.1 International Market

Bio-organic compound fertilizer is a new product of high-efficiency, pollution-free and environmental-friendly fertilizer, also known as green fertilizer, representing the latest level and trend of current fertilizer application technology, which contains a large amount of organic matter, certain biological bacterium and synergist to meet the nutritional needs of crops, and contains both efficient nitrogen fixation, phosphorus and potassium removal active microorganisms, as well as rich organic matter and trace elements. It can activate and fertilize the subsoil layer, thicken the tillage layer, increase the content of soil organic matter, improve the output efficiency and use coefficient of the land, continue and protect the land resources, so as to achieve the role of fertilization and soil improvement. It has the advantages of no pollution, no pollution, long-lasting fertilizer, strong seedlings and disease resistance, improved soil, increased yield and improved crop quality, but also to overcome the use of chemical fertilizers, pesticides brought about by environmental pollution, ecological damage and other disadvantages. According to the test results, the application of bio-organic fertilizer, generally can make grain and oil crops yield 10% to 20%, vegetables, fruit trees and other high-efficiency economic crops yield 20% to 30%, is the development of "green food" and high-quality environmentally friendly agriculture ideal products. Bio-organic fertilizer raw materials are easily available, turning waste into treasure, reducing pollution and improving ecology. Bio-organic fertilizer using organic resources, generally livestock manure, crop straw resources, urban waste and other waste, after processing into fertilizer, can reduce pollution and improve the role of the environment, while also turning waste into treasure, so that fertilizer resources can be reused. The use of high efficiency and quality organic fertilizer in foreign developed countries has formed a consensus, the amount of organic fertilizer in the United States accounted for more than 68% of the entire agricultural fertilizer, in the United Kingdom, the Netherlands is also higher than this proportion. In China, the production of high-efficiency bio-organic fertilizer is still a new industry, I believe that with the development and progress of society, especially the export of foreign exchange-generating agricultural development, the demand for efficient organic fertilizer will be unlimited.

2.2.2 Domestic Market

China's pollution-free, pollution-free, green food development is rapid, consumption at an annual rate of 7.5% increase. 2007, the national pollution-free, green, organic "three products" planting area has developed to 450 million mu, accounting for 1.8 billion acres of arable land in the country 25%. With the rapid development of pollution-free, green and organic agricultural products production, especially the development of export-oriented agriculture.

The demand for bio-organic fertilizers is increasing, and will gradually become a substitute for the existing traditional fertilizers. According to the 2006 bulletin of the National Bureau of Statistics, the domestic production of fertilizer in 2006 was 45,197,900 tons, (excluding the number of various imported fertilizers), the total sales of fertilizers for more than 370 billion yuan, bio-organic fertilizers accounted for 2% of the total, that is, 7.4 billion yuan. Due to the many advantages of bio-organic fertilizer gradually recognized by people plus the national policy tilt, experts estimate: the future market, bio-organic fertilizer will grow at an annual rate of 5%. Then in 2010, the total value of sales of bio-organic fertilizer will reach 90 billion yuan, by 2015 will exceed 150 billion yuan (an average of 5 billion yuan per province). *** As a large agricultural province, with an arable land area of nearly 120 million mu, is an important national production base of high-quality agricultural products. Total food production ranks 1st in the country, vegetable area has exceeded 20 million mu, orchard area reached 7 million mu, the quality and safety of agricultural products are related to the health and safety of the people of the province and even the country, according to the province's average annual application of organic fertilizer per mu of arable land 100 kg is expected, only *** province organic fertilizer market capacity can reach 12 million tons. At present, the province's bio-organic fertilizer manufacturers and production capacity is extremely small, therefore, the construction of 80,000 tons of bio-organic fertilizer production line, to meet the *** market demand, to promote the development of pollution-free agricultural production in *** Province has great significance and broad market prospects.

2.3 Marketing Strategy

2.3.1 Target Market

The main effect of the project is to fertilize the ground, improve the quality of crops, and increase yields and incomes, so the target market of the project is mainly to the rural high-quality food and cash crop arable land, based on the large agricultural provinces. The initial sales range is within a 500 km radius centered on the production facilities, and with the improvement of the logistics and distribution system, the sales range will be gradually expanded to a radius of 800 to 1000 km, and the international market will be explored.

2.3.2 Product and Pricing Strategy

In response to the farmers' use of fertilizers and the structural adjustment of the planting industry, the products of this project are mainly bio-organic fertilizers. In accordance with the laws of agricultural production, the product structure is adjusted in production at the right time to ensure that the products meet the market demand.

As an important agricultural product, product quality and price have a great impact on the market. Therefore, according to the product positioning and market segmentation, we adopt a series and combination of products and price strategy, and use different price and marketing strategies for different consumer groups.

Chapter 3 Construction content and scale

3.1 Construction content and scale

3.1 Construction content and scale

The project uses straw, livestock manure and other agricultural waste, using high-temperature composting and fermentation technology to build an annual output of 90,000 tons of organic fertilizer project. The main construction is fermentation workshop, drying workshop, finished product storage and related supporting facilities and other buildings. The total area is 8650 square meters, and the construction area is 8150 square meters. There are 58 sets of new production equipment such as fermentation tanks and crushers.

After the project is completed, the annual output of organic fertilizer will be 90,000 tons, part of which will be used in the existing 40,000 mu planting base of the enterprise, and the other part will be used by the surrounding farmers and enterprises at cost price as agreed with the local government.

3.2 Product Solutions

3.2.1 Product output: 90,000 tons of bio-organic fertilizer.

3.2.2 Product quality standards

Quality standards for the production of organic fertilizer products to implement the national standards of the People's Republic of China and the Ministry of Agriculture organic fertilizer product standards (NY525-2011).

Chapter 4 Project site and construction conditions

1.1 Project construction principles

*** Utilization of straw annual output of 90,000 tons of bio-organic fertilizer project, is based on the existing annual output of 100,000 pig farms for agricultural waste reuse project, the site selection should follow the following principles.

(1) Having suitable resource conditions

The project requires both livestock farms to provide sufficient livestock manure, straw and other related raw materials, and sufficient farmland in the surrounding areas to consume organic fertilizer products to achieve the purpose of forming comprehensive utilization of resources.

(2) Meet the requirements of town planning

The choice of the center location should be subject to town construction planning, regional planning and related industry planning, and far from residential areas.

(3)Saving investment, reducing cost and improving economic efficiency

Choose the site with convenient transportation and good conditions in all aspects (such as water, electricity, roads, etc.) to save capital construction investment, reduce project cost, save cost and improve economic efficiency.

(4) Meet the requirements of livestock and poultry farm epidemic prevention

To prevent the pathogens in livestock and poultry manure from spreading epidemics, there should be a certain distance from the livestock and poultry farm. The site of manure treatment facility should be chosen downwind of the farm as far as possible, and a special manure transport channel should be set up to prevent cross-contamination of pathogens.

1.2 Construction conditions

1.2.1 Location

*** City is located in the southeastern part of *** Province, in the southern part of the Yellow River Alluvial Plain and the middle reaches of the Shaying River, a major tributary of the Huai River. The geographical coordinates are 114°21′-115°40′ East longitude and 33°03′-33°30′ North latitude. The territory is 49.5 kilometers long from north to south and 35.25 kilometers wide from east to west. It is adjacent to ** County in the west, ** County in the east, ** County across the river in the north, ** County in the south, and ** County in the southeast.

*** is located at the junction of **** two provinces, convenient transportation, ** railroad through the territory, east connected, west connected to the two major arteries high-speed, high-speed interchange in the city, national highways and provincial roads through the territory. City and township (town) roads, rural roads, hardened roads are interwoven.

The project construction site in *** City *** Office *** Village, the company's existing field and planting base, the construction area is flat, fresh air, no other polluting enterprises around, natural conditions are good, convenient transportation, suitable for the construction of the project.

1.2.2 Natural Meteorological Conditions

*** City is a subtropical to warm temperate transition zone, a warm temperate monsoon continental climate. The climate is moderately warm and cold, both north and south of the long, high-temperature period and rainy period consistent with the need to meet the cultivation and growth of a variety of plants: heat-rich, abundant rainfall, conducive to human life and animal reproduction. *** city four seasons, and each has its own characteristics: spring temperature changeable, abundant rain; summer heat and rain, rainstorms often; autumn cool and sunny, moderate precipitation; winter long cold and short, rain and snow fall.

The annual average temperature is ℃. The average temperature is ℃ in spring; ℃ in summer; ℃ in autumn; and ℃ in winter. The average temperature difference between January and July is ℃; the average temperature in July is ℃; the extreme minimum temperature is ℃; the extreme maximum temperature is ℃. The average annual minimum temperature is ℃, and the average annual maximum temperature is ℃.

The average annual rainfall is mm. Geographically, precipitation gradually increases from north to south. The average annual precipitation increases from the north to the south, with millimeters in a year of abundant water and millimeters in a year of extreme drought. Spring rainfall accounts for % of the total annual rainfall; summer rainfall accounts for %; autumn rainfall is slightly the same as spring, accounting for % in individual years; and winter rainfall accounts for about %. Throughout the year, winter and spring are prone to drought, and summer and autumn are prone to flooding.

Due to the influence of monsoon circulation, generally speaking, the winter monsoon prevails to the north in winter and the summer monsoon to the south in summer and autumn. The annual average wind is most northerly, followed by southerly and easterly winds, and least westerly winds. The annual average wind speed is m/s.

The average annual total solar radiation is kcal per square centimeter, the effective light radiation is kcal per square centimeter, and the annual average sunshine hours are hours. The annual average hours of sunshine are hours. The annual average hours of sunshine are hours. The annual average hours of sunshine are hours.

The average first frost day of the calendar year is on January 1, with the earliest occurring on January 1; the average last frost day of the calendar year is on January 1, with the latest occurring on January 1. The average frost-free period is days, the longest year is days, the shortest year is only days, a difference of more than one month. The frost-free period is % and the guarantee rate is days.

1.2.3 Terrain topography

*** The city is located in the Yellow and Huai Plain, with a high topography in the northwest and sloping in the southeast. The elevation of the project is about 1,000 meters above sea level, with the highest local elevation of 1,000 meters. The topography of the project location is flat and open, which is suitable for the construction of the project.

1.2.4 Hydrogeology

*** The city has a total of surface water billion cubic meters, groundwater billion cubic meters, transit water billion cubic meters, the total amount of water resources billion cubic meters, the amount of perennial availability of billion cubic meters, the actual use of billion cubic meters. Most of the groundwater is calcium-magnesium type water quality, suitable for human and animal water and farm irrigation.

1.2.5 Seismic intensity

According to the Earthquake Intensity Zoning Map of China (1990), the area is a 6-degree seismic intensity zone.

1.2.6 Infrastructure conditions

1、Water Supply

The company has complete water extraction facilities, with deep water wells of 80m, 100m, 120m and other depths, with sufficient water sources and excellent water quality to meet the project construction needs.

2、Drainage

The project unit has its own drainage system for farming sewage and rainwater in the plant area. The farm sewage is transported to the centralized treatment of biogas production area through closed pipes, and the rainwater is discharged off-site through the perfect drainage network of the farm, which can meet the project construction needs.

3、Electricity supply

There are special high-voltage lines erected by the farm within the site, which can ensure sufficient power for the construction of this project.

1.2.7 Construction materials and transportation conditions

Construction materials required for the project such as steel, timber, cement, cable, etc. can be supplied by *** City and *** City construction material market.

Chapter 5 Engineering Technology Program

2.1 Production schedule

This project is *** annual output of 90,000 tons of bio-organic fertilizer project using straw, the production of organic fertilizer product quality standards to implement the national standards of the People's Republic of China and the Ministry of Agriculture organic fertilizer product standards (NY525-2011).

2.2 Design Principles

1、Project construction strives for high quality, high starting point, high standard, high technology, high orientation and high efficiency. It has the functions of technology demonstration, technology promotion and business benefits.

2, to "reliable production, advanced technology, save investment, improve efficiency" as the principle, pay attention to the overall configuration of the production line.

3, equipment selection to fully consider the level of development of technology and equipment in the organic fertilizer processing industry, and focus on the reliability of equipment operation, taking into account the advanced, energy-saving, investment-saving factors, the use of domestic and foreign mature and reliable equipment with a certain degree of sophistication.

4, to improve the straw fertilizer as the fundamental starting point, according to the norms of processing enterprises for planning and design.

2.3 Process Technology Solutions

2.3.1 Technology Solution Selection

There are various ways to produce organic fertilizer using crop straw and livestock manure, but the most common way is to compost at high temperature. The high-temperature composting method has the advantages of large daily processing capacity, high speed, high degree of harmlessness (preventing odor emission) and high degree of mechanization and clean production. In addition, when using this method for organic fertilizer production, solid waste such as crop straw can be used for C/N ratio and moisture adjustment, etc., thus resourceizing a large amount of solid waste and solving the problem of outlet for a large amount of crop straw in agricultural production.

Since the moisture content of freshly produced compost is large, which is not easy to store and circulate, and air-dried compost is loose and large, which is not convenient for application, transportation and storage, so the compost is usually processed to improve the physical and chemical properties of compost and increase the added value of organic fertilizer. At present, the subsequent processing of compost at home and abroad, the most common way to extrude compost granulation. Because the granulation of compost can not only reduce the volume of air-dried compost by 40-60%, but also in the processing can be adjusted according to the requirements of customers or the characteristics of crops and soil for the active ingredients of organic fertilizer, in order to further improve the added value of fertilizer, technical content, etc.

Therefore, the implementation of this construction project will choose the high temperature composting method, using raw materials such as livestock manure and crop straw for compost production. In production, the production cycle of organic fertilizer will be shortened to 10 days by adjusting the production process. After decomposition and air-drying, the granulation of compost is carried out by extrusion to further increase the added value of organic fertilizer.

2.3.2 Production Technology Solutions

The project collects digestate and the remaining 10,000 tons of pig manure from pig farms, and then adjusts the moisture content of raw materials to about 50% by adding biological strains and crushed crop straws and other auxiliary materials, and adopts fermentation tank fermentation, with ventilation at the bottom of the tank to improve microbial activity, which effectively shortens the fermentation time, eliminates odor and promotes rapid maturation of fermented raw materials, while using the high temperature generated by fermentation to kill pathogenic bacteria and insect eggs and ensure the sanitary standard of fertilizer. Ensure the fertilizer meets the health standard.

In order to ensure that the bio-organic fertilizer production line fully meets the requirements of environmental protection, the process design fully takes into account the requirements of dust removal during the flow of materials, and dust removal devices are added in many processes to meet the environmental requirements. In addition, biological deodorization and dust removal facilities are added in the whole fermentation workshop and drying and granulation workshop, so that the production process will not cause any harm to the environment.

2.3.3 Process Flow

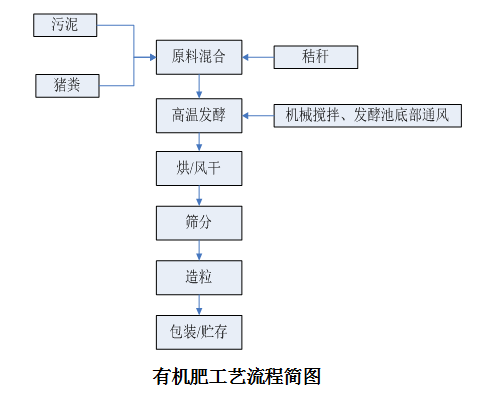

The process of producing organic fertilizer by high temperature fermentation of pig manure and crop straw is shown in the figure below.

1.1.1 Process Description

①Pre-mixing process

The collected pig manure, etc. and crushed crop straw are added to the biaxial premixer for mixing, adding fermentation bacteria and adjusting its moisture to about 50%, and then sent to the fermenter by belt conveyor for aerobic high temperature fermentation.

②Fermentation process

The mixed fermented materials are transferred to the fermenter of the fermentation workshop by belt conveyor and piled up at 1.2m thickness, after which the operator must monitor the temperature change of the materials in the pool in time and turn on the tumbler to turn the materials at the right time. The ventilation device is designed and installed in this section, and the oxygen supply device is activated as needed to provide oxygen to the materials in the troughs; the air exchange device in the workshop is activated to change the air in the room to ensure the normal fermentation of organic materials and eliminate the odor.

③Drying, crushing and granulating process

The fermented material is about 40% moisture, can be transferred to outdoor drying field to dry, after sieving machine to remove metal and large stones and other debris, it will be dried, crushed, granulated, packaging, etc.

1.1.2 Main process technical parameters

Specific gravity of premixed material 0.4-0.6

Fermentation material moisture 50-60%

Fermentation cycle 7-10 days (under the condition of sufficient oxygen supply)

Fermented material pile height 0.8-1.2m

Mechanical stirring 1-2 times/day

Ventilation at the bottom of the fermenter 100L/min.m3, 2 times a day, 2 hours each time

1.1 Technical Features

①This project is made by using pig manure and adding appropriate amount of crop straw through high temperature fermentation, the product has no odor, no harmful bacteria, and does not contain weed seeds or ingredients harmful to crop biological development, so it is a real "ecological fertilizer" or "green fertilizer".

②The project adopts unified fermentation and unified preparation to produce, so the product has uniform quality, high organic matter and nutrient content, stable fertilization effect, and safer and more reliable application.

③The project makes full use of bio-energy and solar energy in production, so the production cost is low and the price is cheap, thus the market competitiveness is strong.

④The project is a granular fertilizer made by extrusion of matured compost, which is small in size and low in moisture content, and is therefore conducive to reducing the transportation cost of fertilizer, easy storage and mechanized fertilization.

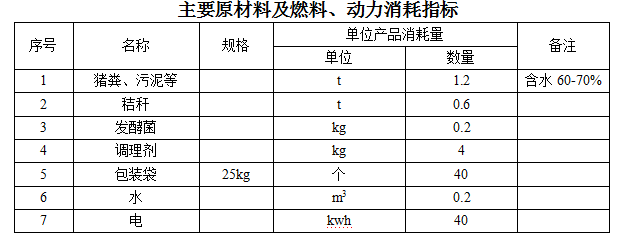

1.2 Main raw materials and fuel and power consumption indicators

1.1 New equipment

① Pre-mixing equipment (according to WTH-750 type)

Design parameters: collect sludge and pig manure, etc. from each pig farm of the company, use crop straw to adjust the moisture to 50% and then ferment the total weight of raw materials about 144,000 tons/year, 300 working days per year, two shifts per day, 8 hours per shift.

Hourly output: 12 times/hour × 1m3/time × 0.6 tons/m3 = 7.2 tons;

Daily production: 7.2 tons × 8 hours = 57.6 tons;

Annual single-shift production: 57.6 tons × 300 days = 17.28 million tons/year;

Annual output in two shifts: 1.728×2= 34.56 million tons/year;

3 sets of WTH-750 premixer can be selected to meet the output requirements.

② fermentation tank (according to the length × width × height = 70 m × 7 m × 1.5 m for a count)

Design parameters: 300 working days per year, three shifts per day, 8 hours of work per day.

Fermenter capacity/strip: 1.5m x 70m x 7m x 0.8 tons/m3 = 588 tons

Annual output: 588 tons ÷ 10 days × 300 days = 17,640 tons/strip

Need fermenter: 144000 tons ÷ 17640 tons/strip = 8

第6章 General transportation and public auxiliary works

2.1 General layout

2.1.1 General layout principles

1, according to the national land use policy, policy, and combined with the local situation, in order to meet the requirements of use, to achieve economic, reasonable, minimize investment, reduce the cost, and should pay practical attention to saving land.

2、The general layout of the site should be clear for functional partitioning. The fermentation workshop should be arranged on the downwind side of the minimum frequency wind direction in summer. The processing and finished product storage should be arranged on the upwind side.

3, according to the process and fire prevention requirements, the production of close collaboration of workshops organized together, and strive to achieve a reasonable building layout, clear functional zoning, in the premise of meeting the requirements of the process, as far as possible to achieve a simple and smooth production line, to avoid round-trip transportation and crossover of the line of work.

4, in order to meet the requirements of the production process, according to the nature of production, power supply, freight turnover, health and fire conditions such as zoning arrangements, and will have a lot of smoke, dust and harmful gas emissions of the workshop, arranged in the downwind direction of the field.

5、Transportation is the prelude and continuation of the production process, it is the link between the production links, the general layout to achieve a reasonable layout of the flow of people, traffic transport lines, in order to facilitate the smooth production line, reduce energy consumption, to ensure transportation safety.

6, the layout of buildings or structures should be in line with fire prevention, health norms and various safety requirements, and should meet the requirements of above-ground and underground engineering pipeline auxiliary and transportation.

2.1.2 Project composition

According to the process plan and production needs, the main production workshop of the project includes fermentation workshop and drying workshop. The auxiliary production workshops include raw material stacking shed, finished product warehouse, substation, water pump room, etc. The total area is 8650m2 and the total construction area is 8150m2.

2.1.3 General Layout

The site of the project is located in the existing site of *** Village***, *** Office, *** City. The south is farmland, the whole site is about 780m long from east to west, 500m wide from north to south, the total area within the fence is 585 mu. In order to rationalize the use of land, in line with the principle of clear functional partitioning, reasonable process flow, smooth internal and external transportation and easy production management, the general layout of the design will be divided into four main functional partitions, namely, raw materials area, production area, finished products area and plant area, where the raw materials area is mainly poultry manure The raw material area is mainly poultry manure and straw shed, located in the southwest of the plant, the production area includes fermentation, drying and other workshops, which are centrally located in the south of the plant, downwind of the dominant wind direction in the region, to reduce air pollution to the surrounding villages and enterprises in the front of the plant, and auxiliary production facilities are located in the north of the plant, forming the front of the plant. Pelletizing workshop and finished product warehouse are located in the north of the production area, forming the finished product area.

2.1.4 Entrance and exit settings

According to the location of the enterprise, the scale of production and the general layout of the plant, the entrance ensures the separation of human and cargo flow and the net and turbidity flow. The west entrance is located in the production area, mainly for raw materials and finished products, to avoid interference with human flow. The south entrance is located between the factory front area and the finished products area, which is the entrance for human flow, completely avoiding the intersection of human and goods flow.

2.1.5 Road and greening system

On-site and off-site transportation of this project are all by car, and the main transportation volume is 230,000 tons/year, so there are more transportation vehicles. The road system in the plant is two kinds of main roads and secondary roads, and the main roads are mainly distributed around the raw material and finished product areas, which bear the transportation function of raw materials and finished products, so the main roads should have enough width. In addition, the road connecting the entrance and exit of the plant and the production site is a secondary road with a width of 12 meters, and the road width of the secondary road is 4.5-6 meters. The road surface structure is all made of cement concrete pavement. The road drainage is covered open ditch. The total length of the road is 1040 meters, and the area of road, square and hardened ground is 3000 square meters.

Greening arrangement is an important measure for environmental protection, so it must be considered comprehensively with the general layout according to specific requirements and coordinated with the site environment. According to the nature of the enterprise, the scale of the product and the general layout plan, in order to eliminate or reduce the dust and gas generated in the production process and noise pollution of the environment, to create a good production and living environment. Greening tree species should be selected according to local conditions to bring into play the greening benefits as soon as possible. Without affecting the traffic, above-ground and underground pipeline operation and maintenance conditions, in the front area of the plant to focus on the green space, its tree species selection is appropriate to reduce noise branching low, large and dense crown, hard leaves of aspen, maple, hedge, etc., to create a small area of green landscape. Another greening component of the production area is the street trees and green areas along the road, forming a belt greening. In between, trees and shrubs are planted together to create a relaxed and comfortable green landscape. The greening layout of the whole plant area forms a greening hierarchy and spatial structure that is sparse and dense, low and high, far and near, so as to echo with the buildings in the plant and build a typical model of a modern factory. The total greening area is 1480 square meters, and the greening factor is 32%.

2.1.6 Vertical arrangement and site drainage rainwater

The project plant area is flat, and the site vertical design is based on the principle of using natural terrain as much as possible to reduce the amount of earthworks. At the same time, the site should have a complete and effective rainwater drainage system to meet the requirements of production, transportation, loading and unloading and engineering pipeline laying. The site elevation and drainage slope should be leveled with the original topography as far as possible, and the site drainage rainwater slope should be 5‰, and the rainwater should sink into the side ditch of the road inside the plant, and finally discharged into the regional flood ditch on the west side of the plant. Therefore, the elevation of the whole site should be high in the east and low in the west, and 0.3 meters higher than the regional road on the west side.

2.1.7 In-plant and out-plant transportation

The total annual transportation volume of this project is 230,000 tons, of which 150,000 tons/year is transported in and 80,000 tons/year is transported out. Forklifts and trolleys are used for in-plant transportation. The transportation means outside the plant is mainly by car, which is mainly solved by social transportation force.

2.2 Civil engineering

2.2.1 Design basis

Building Design Fire Code (GB50016-2006)

General Rules for Civil Building Design (GB50352-2005)

Code for Structural Loads of Buildings (GB50009-2001)

Code for Seismic Design of Buildings (GB50011-2001)

Code for the Design of Concrete Structures (GB50010-2002)

Code for the Design of Masonry Structures (GB50003-2001)

Code for the Design of Steel Structures (GB50017-2003)

Code for the Design of Building Foundations (GB50007-2002)

The architectural design of each workshop is mainly based on the use of production process, meteorological conditions, building shape and building technology and other factors for plan layout and space combination.

2.2.2 Main building scheme

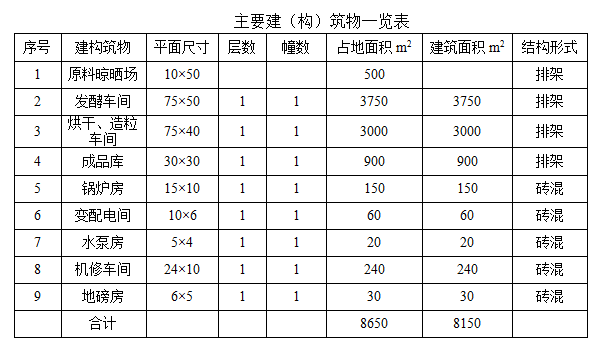

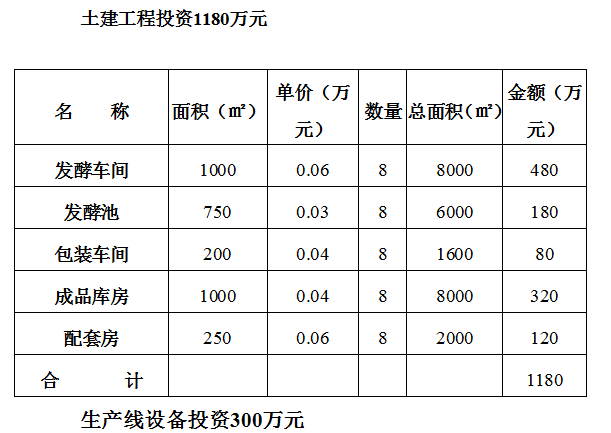

The project builds a new organic fertilizer processing workshop in the existing plant, including raw material drying yard, fermentation workshop, drying workshop, granulation workshop, finished product storage, boiler room, power transformation and distribution room, machine repair workshop, water pump room, weighing scale room, etc.. The total area is 8650㎡, and the construction area is 8150㎡. Specific workshop dimensions are as follows.

Fermentation workshop: the plane size is 75×50m, single layer, construction area is 3750m2;

Drying and pelletizing workshop: the plane size is 75×40m, single storey, and the construction area is 3000m2;

The above building is a single-story row frame structure, roofing with cast-in-place concrete beams, slabs and polymer modified asphalt waterproofing membrane, doors and windows with aluminum alloy, flush steel doors, walls with cement mortar plaster, 888 imitation porcelain paint, cement floor, building exterior wall practices using light-colored paint, the foundation using concrete independent foundation.

Finished goods warehouse: the plane size is 30×30m, all are single-story reinforced concrete row frame structure, the construction area is 900 m2. the warehouse adopts color steel compression composite board, doors and windows adopt aluminum alloy, flush steel gate, the inner wall surface is cement mortar plaster, 888 imitation porcelain coating, the ground adopts floor tiles, the building exterior wall practice adopts light color coating, the roof adopts light steel frame, brick wall enclosure, the foundation adopts concrete independent Foundation.

Distribution room, boiler room and pump room: plan size of 10 × 6m, 15 × 10m and 5 × 4m, are single-layer mixed brick structure, construction area of 60 m2, 150 m2 and 20 m2, respectively. building are used two cloth three oil waterproof membrane roofing. The doors of the transformer and distribution room are made of transformer room doors, and the windows are made of solid belly steel windows; the doors and windows of the boiler room are made of flush steel doors, and the windows are made of plastic steel windows; the doors and windows of the pump room shall be made of wooden doors and aluminum alloy sliding windows. The interior wall is cement mortar plaster, 888 imitation porcelain paint, the floor is made of floor tiles, the roof is made of prestressed concrete hollow slab, and the foundation is made of concrete strip foundation.

Machine repair workshop: the plane size is 24×10m, single storey, construction area is 240m2.

Weighbridge room: plane size is 6×5m, single layer, construction area is 30m2

The doors and windows of the machine repair workshop and weighbridge room are made of wooden doors and aluminum alloy sliding windows. The interior wall surface is cement mortar plaster, 888 imitation porcelain paint, the ground is made of floor tiles, the roof is made of prestressed concrete hollow slab, and the foundation is made of concrete strip foundation.

2.2.3 List of main buildings

1.1 Water supply project

1.1.1 Water consumption and water quality, water pressure requirements

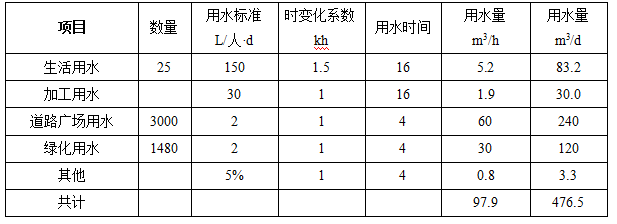

1、Water consumption

(1) Water consumption for living: the total number of employees in the project is 25, the index of water consumption for living is 150L/person/day, and the water consumption for fire-fighting is calculated separately.

(2) Production water consumption: 30m3/d for the production of the project.

(3) Water consumption for road square and greening: water consumption is calculated as 2L/m2.

Water consumption is calculated as follows.

Water consumption list

2、Water quality and water pressure requirements

The project various water for well water, drinking water quality standards should be in line with the national drinking water standards GB5749-85.

The water pressure at the entrance of the water supply pipe at each water use is not less than 0.2MPa.

1.1.1 Water source and water supply facilities

The project site is rich in water resources, and the water demand for domestic water can be met by drilling wells in the plant.

1.1 Drainage

1.1.1 Drainage volume

The drainage volume of the project is 80% of the water supply, and the daily drainage volume is 381.2m3/d, and the maximum hourly drainage volume is 78.32m3/h.

1.1.2 Drainage scheme

The factory wastewater is mainly domestic wastewater (manure is discharged after treatment by septic tank), and the rainwater discharge is discharged by self-flow using the topography of the site.

1.2 Water for fire-fighting

The water consumption for fire-fighting is calculated according to "GBJ16-87", and the water consumption for outdoor fire-fighting is 15L/S, and the water consumption for indoor fire-fighting is 10L/S. The maximum hourly water consumption for fire-fighting is 90 tons/hour.

The designed water supply capacity of the project fire-fighting facilities is 100 tons/hour, which can meet the fire-fighting water demand of the project.

The fire-fighting system of the factory is: outdoor fire-fighting adopts low-pressure fire-fighting system, and the control radius is 80 meters to design three-outlet ground fire hydrant, and the supporting fire-fighting water supply network forms the fire-fighting water supply system.

1.3 Power supply and distribution

1.3.1 Design of power supply system

1、Power supply

The project site is rich in power resources and the transformation of agricultural power has been completed. A 10KV line is introduced from the substation near the project site as the power supply, and the power supply of the project is reliably guaranteed.

2、Load calculation

The total installed capacity of the project is calculated to be 847kW.

The project will build a power substation in the factory, and choose 2 sets of 500kVA power transformers and corresponding power distribution facilities.

4、Substation

(1) substation and distribution house: the cable in and out of the substation adopts the lower into and lower out of the high-voltage cabinet, and the low-voltage cabinet adopts the lower out of the line. Cable in and out of low-voltage cabinet adopts the upper-in and upper-out line mode.

(2) Transformer and distributor system: the high-voltage side adopts single busbar mode, plus electrical and mechanical interlocking, running in parallel; the low-voltage side is equipped with contact, when one power supply loses power, the other power supply can take part of the load.

(3) relay protection mode: the high-voltage side of the transformer is proposed to use three-phase overcurrent, quick-break, single-phase grounding protection and transformer over-temperature alarm.

(4) Power factor compensation mode: set up a set of electrostatic capacitor automatic compensation device on the low-voltage side of the transformer to make the high-voltage side power factor increase to above 0.92 in the form of centralized compensation.

5、Low-voltage distribution line laying mode

Low-voltage distribution adopts the bridge laying method and partial buried wall and ground dark laying. All fire-fighting loads are supplied with double power supply, and a double power supply automatic switching box is set, and the end distribution box switches the power supply. The public lighting in the stairwell and machine room are powered by special lighting switching box, in which the emergency lights and evacuation indicators come with their own batteries, and the emergency time is not less than 30 minutes.

(1)The 10KV line uses YJV-10KV type cross-linked cable laid outdoors in the ground.

(2) The feeder lines of low-voltage distribution cabinets are laid by cable bridges or dense copper busbars, and the distribution lines leading to fire-fighting equipment are made of fire-retardant B-class fire-resistant cables.

(3) Lighting and power distribution lines are laid in walls, floors or ceilings with BYJ-750 cross-linked polyethylene insulated halogen-free low-smoke copper-core wire through pipes.

6、Lighting

The lighting fixtures are made of different types of energy-saving lamps and lanterns, and designed according to the corresponding illumination standards. The lighting fixtures use energy-saving fluorescent lamps as the main light source, and the indoor sockets are configured according to the needs to meet different electricity demands.

In the factory road the form of single-side deployment of lights is used. It is recommended to use high quality, long life, high luminous efficiency and good consistency lamps.

7、Grounding system

The grounding device mainly uses the foundation ground pile and sets artificial grounding pole on the outside of the building. In the power supply system, all substation and distribution equipment are grounded. All equipment electrical control parts and metal pipes in and out of the building are reliably connected to the grounding system at the entrance.

The grounding resistance of the main building of the project Rd≤4Ω, and the grounding resistance of other minor buildings Rd≤30Ω.

1.3.2 Selection of power supply facilities

The power transformer is S11 type product, which is the national recommended energy-saving product. The supporting high-voltage distribution cabinet is GG-1A(F), low-voltage distribution panel is PGL2, and low-voltage capacitor panel is PGJ1, which is the matching type for low-voltage distribution.

1.4 Ventilation

The water vapor and odor generated in the site is sent to the biological filtration and deodorization pool built outside the shed using centrifugal extractor, and the odor is eliminated by biological methods.

Natural ventilation is used in all other buildings to ensure a good working environment for workers.

1.5 Metering

1.5.1 Material and power consumption measurement

1、The raw materials are measured and used, and the finished products are weighed and packed.

2、Water supply pipeline is equipped with water meter well.

3、The power supply is equipped with electricity meter on the 10KVA side, and low voltage electricity meter is installed on the large power equipment for electric energy measurement.

1.5.2 Metering institutions

Part-time metering staff is set up in the Production Technology Department, which is responsible for the metering work of the whole plant.

Chapter 2 Environmental Protection

2.1 Construction site environmental status

The project area is flat and surrounded by good environment without any pollution sources.

2.2 Main pollutants and pollution sources

The pollutants and pollution sources generated by the project in the course of operation are mainly wastewater, solid pollutants and noise. The details are divided as follows.

1. Dust and waste gas

Many aspects of fertilizer production will generate dust, such as transportation, mixing, crushing, screening and packaging of materials.

For livestock manure waste gas, the main pollutants are ammonia gas produced by organic matter decay, and hydrogen sulfide gas produced by protein decay in animal organisms.

2、Solid pollutants

Waste residue is mainly solid pollutants such as livestock manure and fertilizer from farms.

3、Noise

Noise is mainly from fans, processing equipment and other equipment, with sound intensity around 80-110 decibels.

4、Wastewater

Wastewater is mainly site washing wastewater, manure and urine, etc., and a small amount of domestic wastewater.

2.3 Treatment plan

2.3.1 Basis

1、Water Pollution Prevention and Control Law of the People's Republic of China

2、Noise Pollution Prevention and Control Law of the People's Republic of China

3、Law of the People's Republic of China on the Prevention and Control of Environmental Pollution by Solid Waste

4、Regulations on environmental protection management of construction projects (State Council Decree No. 253)

2.3.2 Implementation standards

1, the State Environmental Protection Administration, "livestock and poultry breeding pollution prevention and management measures" (2001.5.8);

2, "Livestock and poultry farming pollution prevention and control technical specifications" (HJ/T 81-2001);

3, "livestock and poultry farming pollutant emission standards" (GB18596-2001);

4, "comprehensive sewage discharge standards" (GB8978-1996);

5、Atmospheric Environment Quality Standard (GB3095-1996).

2.3.3 Three waste management scheme

The main pollutants of this project are solid waste and waste water. In view of the special characteristics of organic fertilizer processing industry, comprehensive management measures will be taken to effectively strengthen pollution prevention.

1、Dust management program

Add dust removal equipment in the processing workshop and strengthen the management of stacking of semi-finished products to control the generation of dust.

2、Noise management program

For the noise generated by the equipment, take the necessary damping measures in production to reduce the noise to below the index specified in the environmental protection standards to ensure a good production environment.

3、Atmospheric treatment program

The harmful gases of this project are mainly generated in the transportation of raw materials and fermentation workshop, and the transportation process is closed as far as possible to reduce emissions; the fermentation workshop adopts filtering ponds to deodorize the harmful gases generated during the fermentation of livestock and poultry manure.

2.4 Greening

Adequate green belts are considered in the layout design of the general plan to maintain good ecological environment and health standards.

2.5 Environmental impact assessment

The project follows the development viewpoint of ecology and economics, meets the requirements of sustainable development of ecological agriculture, takes ecological agriculture theory as the guide, relies on high technology, reflects the advantages of modern ecological agriculture and environmental protection agriculture, realizes the resourceization of pollutants, promotes the circulation of material and energy, and forms an economic, rational, complete, multi-level and multi-functional virtuous cycle system. For the pollution generated by the project, after comprehensive and scientific treatment, the wastewater will be treated to meet the national emission standards, and the pollution generated in the production can be effectively managed.

After the implementation of the project, no new pollution will be generated in the project area and the surrounding environment. The wastewater and waste residue produced in the production can be effectively controlled and utilized. All emissions can be digested and utilized locally, and will not be discharged to the outside world.

Chapter 3 Energy and water conservation

3.1 Energy saving

Energy conservation is a long-term strategic policy for national economic development. Energy conservation refers to strengthening energy management, adopting technically feasible, economically reasonable and environmentally and socially affordable measures, reducing losses and wastes in all aspects from energy production to consumption, using energy more effectively and rationally, improving energy utilization efficiency and economic efficiency, so as to protect the environment, guarantee the development of national economy and society, and meet people's living needs. According to the different stages of project construction, take corresponding measures to save energy.

3.1.1 Energy-saving principles and measures

1. Conscientiously implement national and industry energy-saving norms to achieve reasonable use and economical use of energy.

2、Actively adopt advanced energy-saving new technologies, new techniques and new equipment, and strictly prohibit the use of the eliminated mechanical and electrical products that have been announced by the state.

3、Set up energy detection meters and strengthen the measurement and management of energy in enterprises.

3.1.2 Energy consumption status

This project is mainly a pig farm circular economy construction project. It is mainly the organic fertilizer workshop that consumes energy, and the main energy type is electricity. According to the scale of 80,000 tons of organic fertilizer production, the annual power consumption of the enterprise's organic fertilizer production workshop is 6.1 million kWh.

3.1.3 Energy-saving measures

1, the design of equipment selection is very important for the implementation of energy conservation, so the selection of major equipment should adhere to the selection of energy-saving indicators of advanced equipment. Such as fans and other equipment to choose the domestic advanced level of equipment.

All electromechanical equipment in this project will not use electromechanical equipment with backward energy-saving indexes.

2. Adopt reasonable distribution methods, choose energy-saving products for electrical equipment, use energy-saving transformers, use electrostatic capacitors for low-voltage distribution and low-voltage centralized compensation to improve power factor, and promote green lighting engineering products for lighting design to save energy.

3.2 Water conservation

The project is to use straw and the livestock manure discharged from the existing pig farm of the project unit to manufacture organic fertilizer, the project itself uses little or no water, the construction of the project is not only to turn waste into treasure and realize waste utilization, but also to reduce the water consumption of the whole area to achieve the purpose of water conservation.

Chapter 4 Labor Safety and Health and Fire Fighting

4.1 Labor protection and safety and health

4.1.1 Preparation basis and standards

1, "Construction Projects (Engineering) Labor Safety and Health Supervision Regulations" Ministry of Labor of the People's Republic of China Order (No. 3);

2. "Design Health Standards for Industrial Enterprises" TJ36-T9;

3, "Design Code for Electrical Installations in Explosion and Fire Hazardous Environments" GB50058-92;

4, "Construction Design Fire Code" GBJ16-87 (1995 revised version).

4.1.2 Design principles

In order to implement the policy of "safety first, prevention first", to ensure that the requirements of occupational safety and health are met after the production, and to guarantee the safety and health of workers in labor, the design of this project implements the principle of considering occupational safety and health facilities and the main project at the same time.

4.1.3 Analysis of occupational hazard factors in the production process

There are high temperature, high humidity places and corrosive places in the production process.

4.1.4 Occupational safety main measures

1、Production equipment are used low-noise equipment, fans, pumps, etc. In addition to the use of low-noise equipment, but also the use of vibration damping, sound insulation, sound dissipation and other measures to reduce the noise to 65-75dB allowable range.

2、According to the design specifications, ensure that the operator has enough working space and access, and the operating platform is equipped with safety guardrails. Equipment transmission parts are equipped with protective cover. Electrical equipment are equipped with reliable protective grounding device.

3, the general layout, set up the human flow mouth, logistics mouth, avoid cross and roundabout, and try to make the load center and supply sources close to the channel, the safety distance of the building, lighting and ventilation, sunlight, etc. are designed in accordance with the relevant provisions.

4, in order to prevent electric shock accidents, electrical equipment located in a humid environment set leakage protection switch, the charged part should be clearly marked. Implement perfect safety measures at all electric equipment and facilities to ensure safe production for operators.

4.1.5 Occupational safety and health institutions

The occupational safety and health institution of the enterprise is set up in the production technology department, with one full-time employee in charge, which is not considered separately for this project.

4.2 Fire-fighting

4.2.1 Design basis and standard specification

1、The Ministry of Public Security of the People's Republic of China Order No. 30 "Management Regulations for Fire Protection Supervision and Audit of Construction Projects";

2, "Fire Code for Building Design" (GBJ16-87) (revised version in 1995);

3, "Code for the design of electrical installations in explosive and fire-hazardous environments" (GB50058-92);

4, "Building fire extinguisher configuration design specifications" (GB50166-92).

4.2.2 Analysis of fire hazards in the production process

Some of the raw materials used in the production of this device are flammable and explosive, so the development and supervision of fire prevention measures should be strengthened.

4.2.3 Fire environment condition

The processing base has full-time fire prevention personnel, who regularly report and contact with the municipal fire protection system, and regularly inspect and maintain the fire protection equipment in the plant, so that the fire protection facilities in the plant are in good condition.

4.2.4 Electrical fire prevention

Install fire walls and fire doors in cable trenches, and use fire-resistant materials to block walls in cable shafts and cable through-wall holes.

Use cable channel boxes at fire-prone places and fireproof materials at important circuits such as overhead cables.

4.2.5 Fire prevention measures

Ensure sufficient fire spacing between production units and production plants, and arrange the more dangerous areas in the downwind direction as much as possible. Improve fire-fighting measures in the project area, and the circulating pool is also used as fire-fighting pool, fire-fighting water pipe network and fire hydrant. Outdoor fire fighting adopts low pressure fire fighting system with 80m control radius. For places with high requirements on fire prevention, adequate fire sand and chemical fire extinguishing equipment are equipped. Ensure the fire safety of important departments.

Chapter 5 Enterprise organization and labor force

5.1 Enterprise organization

5.1.1 Enterprise system

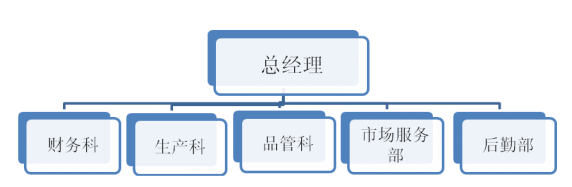

The project contractor is ***, the company implements the general manager responsible system and has a sound organizational structure. There are finance section, production section, quality control section, marketing service department and logistics department.

5.1.2 Organization

The organization chart is as follows.

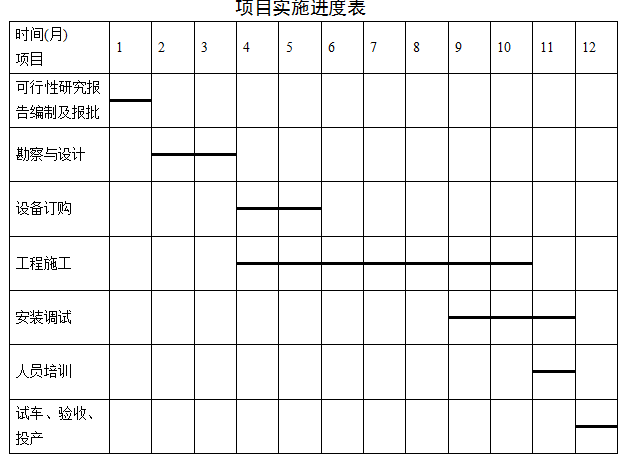

1.1.1 Working system

Production is carried out continuously, except for equipment maintenance time, the annual working days are calculated as 300 days, with three shifts of production per day and 8 hours of work per shift.

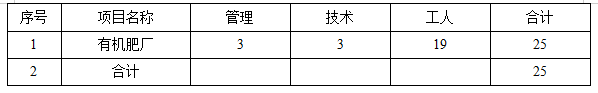

1.1 Labor Quota

The project has 25 employees, including 3 technicians, 19 workers and 3 managers.

List of Labor Quorum

1.1 Personnel sources and training

1.1.1 Personnel sources