Ranch central kitchen grass pre-treatment system

Time:

2023-01-03

Grass pre-treatment systems are systems that pre-treat roughage hay bales and transfer silage for temporary storage prior to the production of full diets

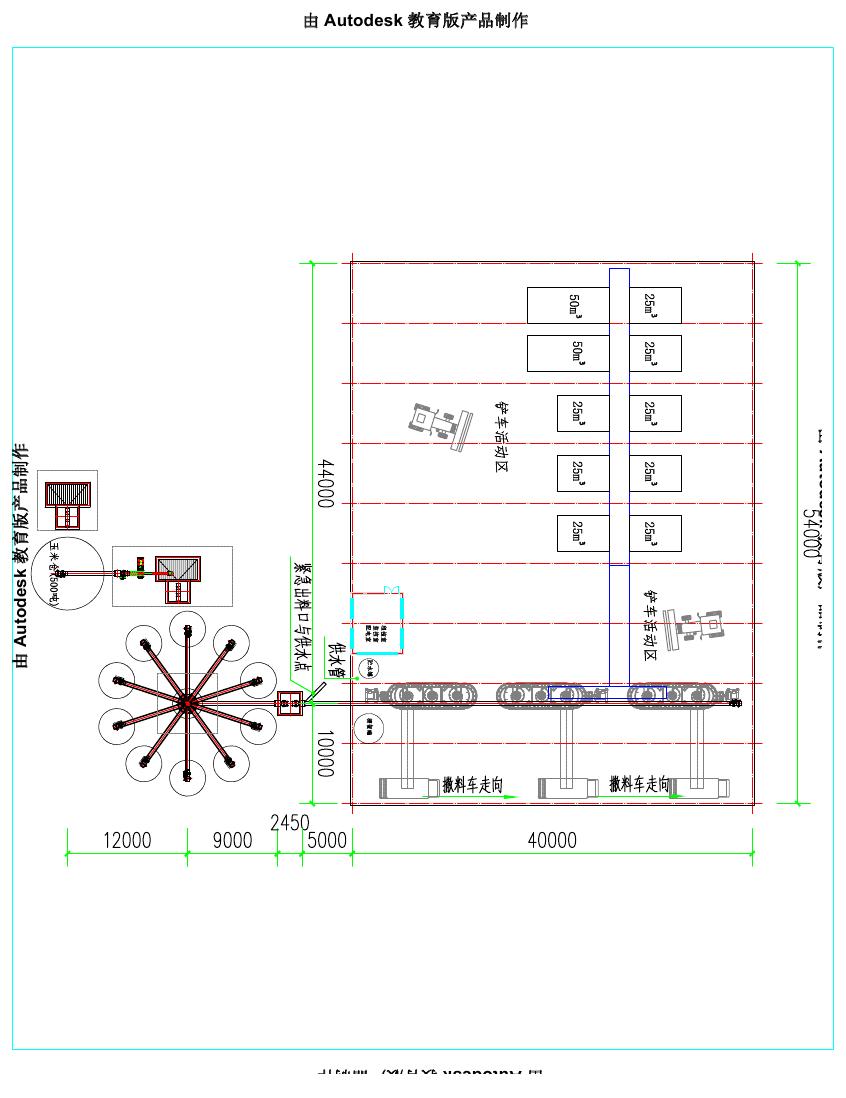

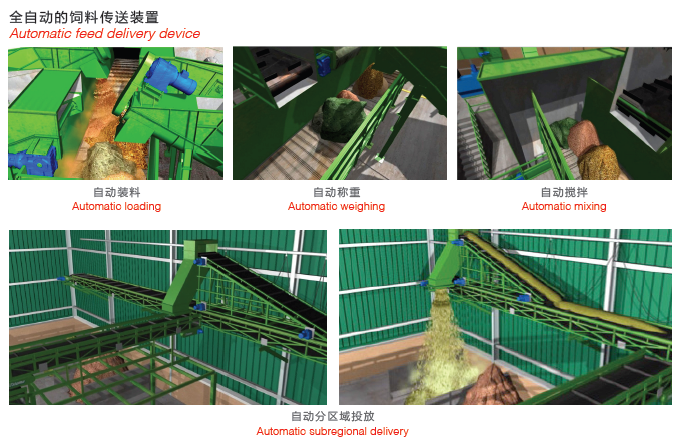

The process flow of hay bale breaking and iron removal pretreatment and loading metering and temporary storage and silage transfer loading metering and temporary storage system is presented in physical diagram. Hay bales are corn stalks, alfalfa grass, oat grass, other types of natural grassland grass by large field operations, through large forage balers and hydraulic dense pressurized baling of square bales of grass or round bales of grass, which is conducive to long-distance transport to save transport costs benefits, ranches purchased these grasses, as a daily whole grain hay added roughage raw materials, before adding the need to lift the bale rope, as the bales are pressurized dense bales need Second break the bale and clear the miscellaneous in addition to iron, large-scale breeding requires a large number of hay feed added, the amount of several dozen tons per day, can not be solved by manual, through mechanized equipment instead of manual break the bale in addition to miscellaneous, greatly improve the processing efficiency, while giving the equipment intelligent weighing add feeding function, by setting the weight of hay ration in each batch of diets, that is, accurate and efficient, in the processing of hay is due to a large amount of dust The specific process is as follows: firstly, the bales are caught by the grass catcher to the belt conveyor - frequency transfer to the untying mechanism, cut out the tie rope and nylon net rope, the rope is collected through the bypass - bale breaker - -Efficient iron remover -Belt conveyor -Hay stacking area (different hay has different stacking area) -Feeding shovel (silage transfer feeding simultaneous operation of the shovel) - metering and weighing hay staging bins (silage metering staging bins) - belt conveyor - dividing plough discharger - The production process of TMR ration mixer, different hay is added separately through the respective feeding mechanism, the hay pre-processing area is generally done in the area set by the hay shed and close to the TMR full ration mixer and is conducive to the convenient mechanical operation of the feeding location, the same silage is fed to the silage staging metering bin through the silage transfer vehicle and the hay is completed with a batch of daily Grain roughage feeding and loading, the location area is shown as follows.

Hay bales are corn stalks, alfalfa grass, oat grass, other types of natural grassland grass by large field operations, through large forage balers and hydraulic dense pressurized baling of square bales of grass or round bales of grass, which is conducive to long-distance transport to save transport costs benefits, ranches purchased these grasses, as a daily whole grain hay added roughage raw materials, before adding the need to lift the bale rope, as the bales are pressurized dense bales need Second break the bale and clear the miscellaneous in addition to iron, large-scale breeding requires a large number of hay feed added, the amount of several dozen tons per day, can not be solved by manual, through mechanized equipment instead of manual break the bale in addition to miscellaneous, greatly improve the processing efficiency, while giving the equipment intelligent weighing add feeding function, by setting the weight of hay ration in each batch of diets, that is, accurate and efficient, in the processing of hay is due to a large amount of dust The specific process is as follows: firstly, the bales are caught by the grass catcher to the belt conveyor - frequency transfer to the untying mechanism, cut out the tie rope and nylon net rope, the rope is collected through the bypass - bale breaker - -Efficient iron remover -Belt conveyor -Hay stacking area (different hay has different stacking area) -Feeding shovel (silage transfer feeding simultaneous operation of the shovel) - metering and weighing hay staging bins (silage metering staging bins) - belt conveyor - dividing plough discharger - The production process of TMR ration mixer, different hay is added separately through the respective feeding mechanism, the hay pre-processing area is generally done in the area set by the hay shed and close to the TMR full ration mixer and is conducive to the convenient mechanical operation of the feeding location, the same silage is fed to the silage staging metering bin through the silage transfer vehicle and the hay is completed with a batch of daily Grain roughage feeding and loading, the location area is shown as follows.

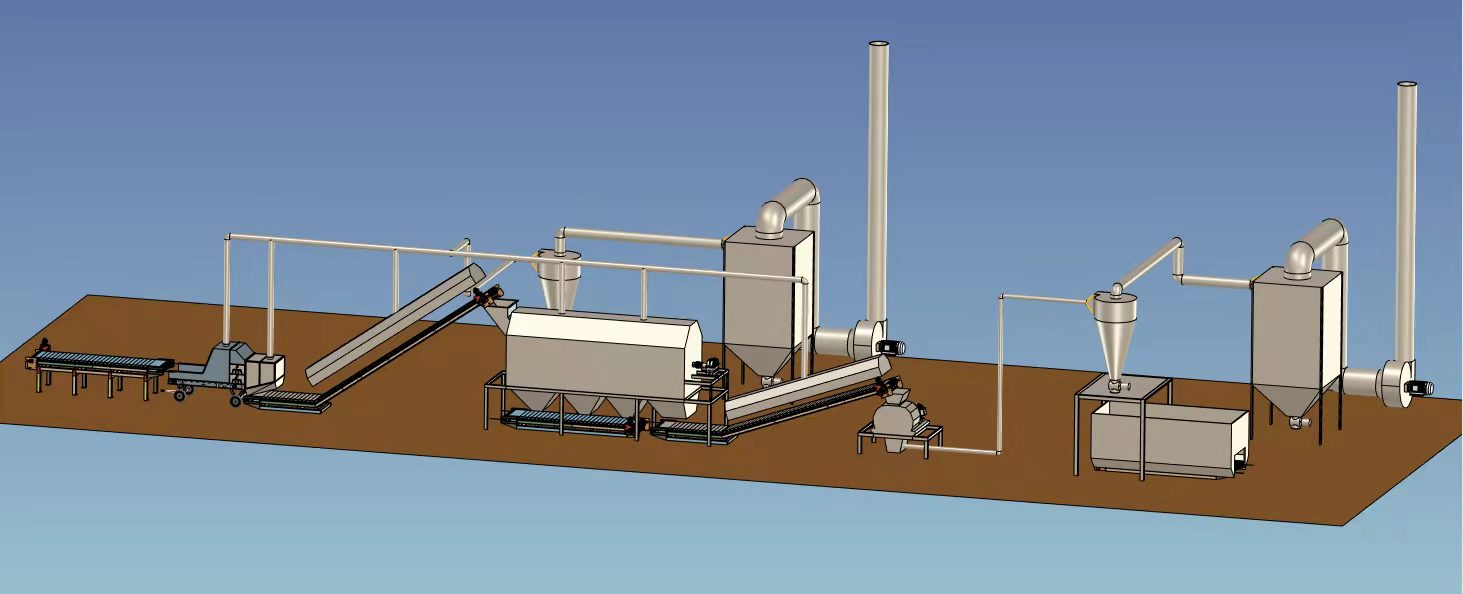

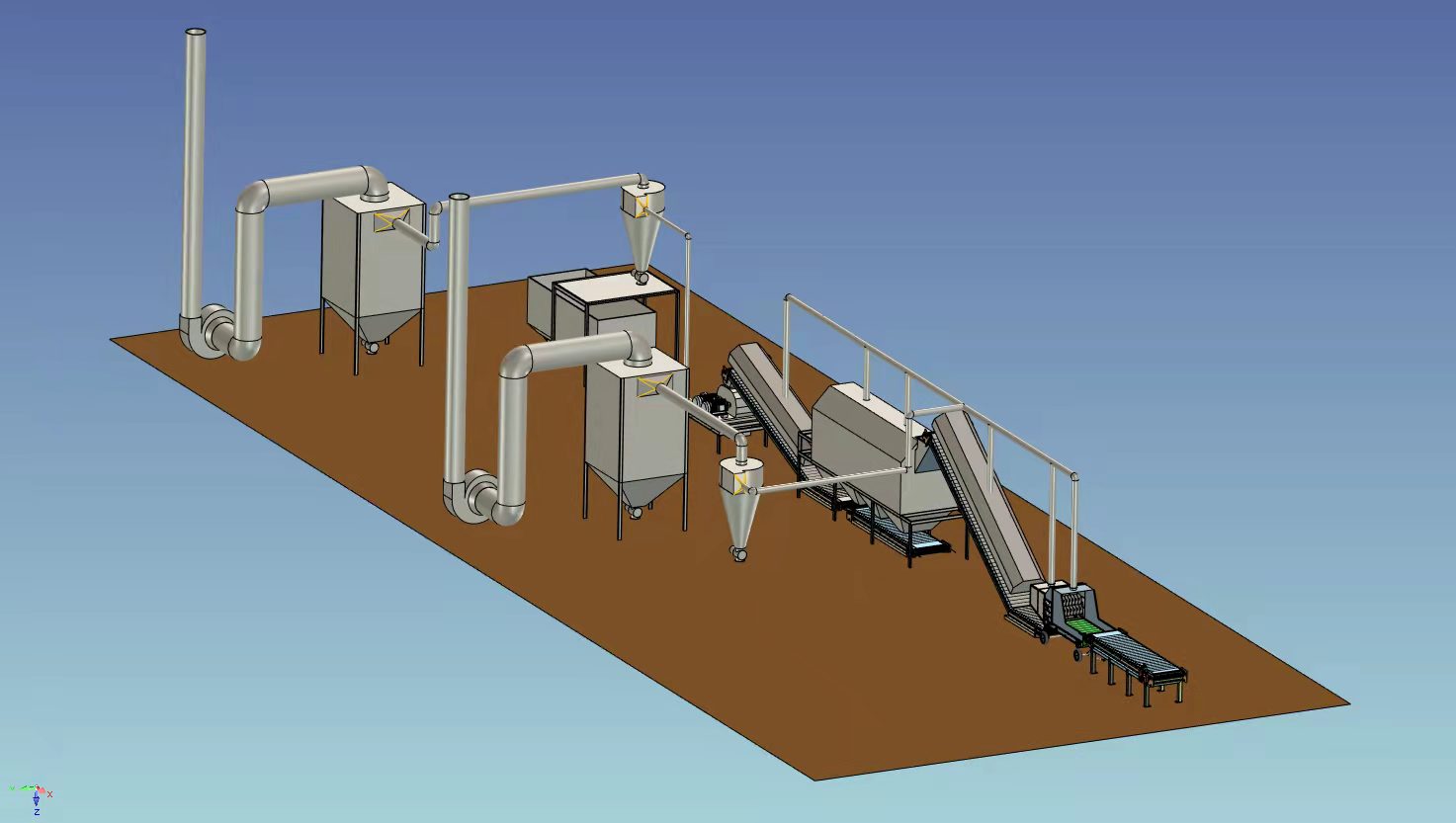

The model diagram of hay pretreatment bale breaking and iron removal is as follows.

The physical picture is as follows.

1. Bundle-breaking and rope-removal iron removal mechanism (with dust removal system).

Treated hay discharge pile area

2: Belt loading system (hay and silage)

3: 35 cubic metered and weighed temporary storage bins (hay and silage)

4: Overall effect

5: Auxiliary transport system

6: Grass pretreatment metering and weighing loading management system interface.

Finished pellets

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Online Inquiry