Unbundling and debundling machine

Time:

2023-01-03

一(yī)、Working Principle:

The unbundling and bale removal machine is a special type of unbundling and bale removal machine developed by our company according to the current collection and storage bale type of forage and straw in the farming industry, and according to the characteristics of small forage capacity and large bale volume. Its working principle.

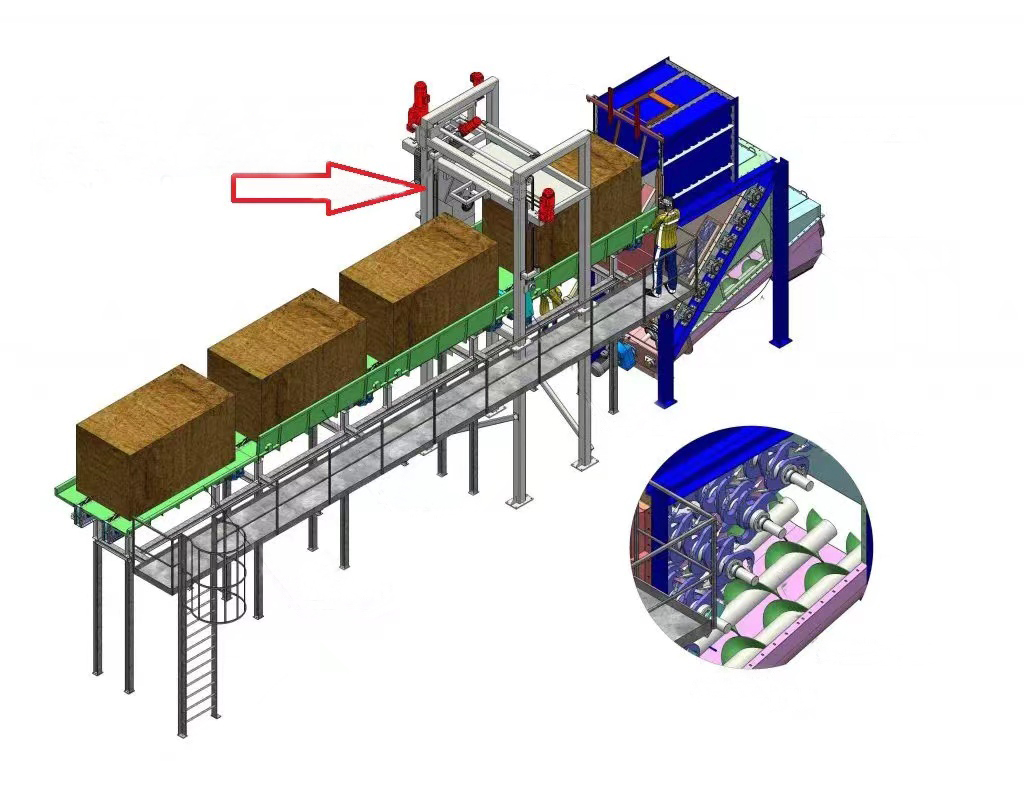

A. The bale is put into the feeding slat chain conveyor by the grass catcher.

B. The chain conveyor evenly conveys the bales to the multi-roller conveyor trough of the unbale unbale machine, and enters the rotary knife unbale mechanism at a uniform speed.

C. The rotary knife unpacking mechanism unpacks the bales from the bag or rope.

D. The bale unpacking mechanism removes the bags or ropes from the unpacked bales, and collects and classifies the bags or ropes in a fixed position.

E. After unbale, the bale is conveyed to the next process by multi-roller conveying chute.

This unbale and de-bale machine solves the problem of de-bale and de-cord of raw material bales for cattle and sheep farms. From the old manual low efficiency unbale, it realizes the high efficiency mechanized unbale. It is a reasonable model for forage processing.

二、Structural features:

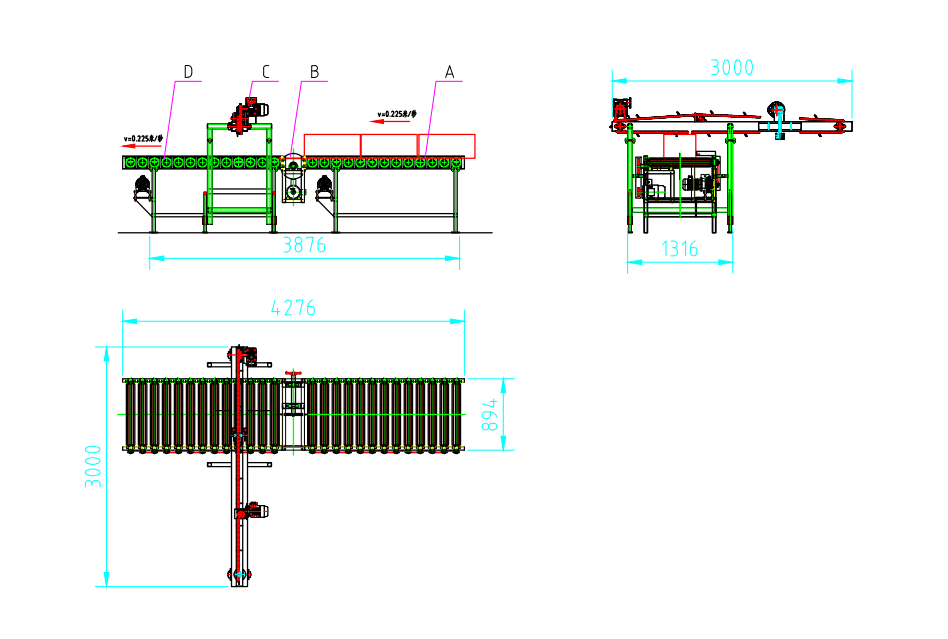

(I) General structural diagram

A. Bale feeding system B. Unbale system C. De-bale and de-cord system

D、Loose bale conveying system

三、Technical parameters and performance indicators

1、Main technical parameters:

| Model | JB743 type |

| Host size | 4300×3000×3000mm |

| Weight of the whole machine (kg) | 600kg |

| Matching power | 3.55kw |

| Spindle speed (r/min) | 2900 r/min |

| Production efficiency (bundle/h) | 450-560 bales/h |

| Material moisture | 小(xiǎo)于18% |

Finished pellets

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Online Inquiry