BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: Multiple materials

- Applications: Mixing of two or more fertilizers, premixes

Classification:

Tel:

Introduction

-

BB fertilizer range mixer is widely applicable. Fertilizer/pharmaceutical/food/mining/dry powder BB fertilizer mixer has high mixing uniformity; it can make 1:10,000 times the proportion of materials mixed evenly, and its standard deviation is three parts per 100,000. BB fertilizer mixer has fast mixing speed and high efficiency. BB fertilizer mixer is fast and convenient, usually 2-5 minutes to finish a batch of material. BB fertilizer mixer mixing process is mild, smooth operation, low noise, basically not destroyed the original state of the material. To the phenomenon of material feeding, the mixing mechanism of the equipment is integral, reliable performance, all the angular welds rounded transition, easy to clean, lubrication Department parts are outside the barrel body without dripping oil and abrasive material infiltration into the material, can be sealed operation, isolated from the air dust into the material. Low energy consumption, large loading coefficient, filling coefficient of 0.7-0.9. Low requirements for the plant, the equipment is horizontal, and various forms of drive devices and discharge position can be arbitrarily selected, not subject to plant height, floor space constraints.

-

-

BB fertilizer mixer overcomes the phenomenon of mixing material lamination or diversion caused by the different specific gravity and granularity of raw materials, and improves the batching accuracy. It solves the influence on the system caused by material characteristics, mechanical vibration, air pressure, voltage fluctuation, cold weather, etc. It has the characteristics of high accuracy, fast speed and long service life, which is the ideal choice for BB fertilizer (blended fertilizer) manufacturers. The main equipment adopts forward and reverse operation, and the material is mixed and output by special internal spiral mechanism and unique three-dimensional structure. The whole set of equipment has the characteristics of low price, small footprint, large output and even mixing. After years of research, our company found that the general requirements of basic fertilizers are uniform particle size, low moisture content, good particle strength, no lumping in storage, and the consistency of the raw material fertilizers used for blended fertilizers, the consistency of particle size, not only requires the same value of the upper and lower limits of particle size, but also requires them to have similar particle size distribution, therefore, the analysis of particle size distribution of different raw materials before fertilizer blending is an important step to ensure the quality of blended fertilizers. According to this problem, the blended fertilizer equipment is researched: the equipment is novel in design and practical, it is mainly composed of lifting feeding system, high-precision mixing system, storage system rack, electric control system, etc. It can be self-flowing packaging, continuous production and other advantages.

-

Finished pellets

undefined

Features

-

- Commodity name: BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: Multiple materials

- Applications: Mixing of two or more fertilizers, premixes

BB fertilizer range mixer is widely applicable. Fertilizer/pharmaceutical/food/mining/dry powder BB fertilizer mixer has high mixing uniformity; it can make 1:10,000 times the proportion of materials mixed evenly, and its standard deviation is three parts per 100,000. BB fertilizer mixer has fast mixing speed and high efficiency. BB fertilizer mixer is fast and convenient, usually 2-5 minutes to finish a batch of material. BB fertilizer mixer mixing process is mild, smooth operation, low noise, basically not destroyed the original state of the material. To the phenomenon of material feeding, the mixing mechanism of the equipment is integral, reliable performance, all the angular welds rounded transition, easy to clean, lubrication Department parts are outside the barrel body without dripping oil and abrasive material infiltration into the material, can be sealed operation, isolated from the air dust into the material. Low energy consumption, large loading coefficient, filling coefficient of 0.7-0.9. Low requirements for the plant, the equipment is horizontal, and various forms of drive devices and discharge position can be arbitrarily selected, not subject to plant height, floor space constraints.

-

-

BB fertilizer mixer overcomes the phenomenon of mixing material lamination or diversion caused by the different specific gravity and granularity of raw materials, and improves the batching accuracy. It solves the influence on the system caused by material characteristics, mechanical vibration, air pressure, voltage fluctuation, cold weather, etc. It has the characteristics of high accuracy, fast speed and long service life, which is the ideal choice for BB fertilizer (blended fertilizer) manufacturers. The main equipment adopts forward and reverse operation, and the material is mixed and output by special internal spiral mechanism and unique three-dimensional structure. The whole set of equipment has the characteristics of low price, small footprint, large output and even mixing. After years of research, our company found that the general requirements of basic fertilizers are uniform particle size, low moisture content, good particle strength, no lumping in storage, and the consistency of the raw material fertilizers used for blended fertilizers, the consistency of particle size, not only requires the same value of the upper and lower limits of particle size, but also requires them to have similar particle size distribution, therefore, the analysis of particle size distribution of different raw materials before fertilizer blending is an important step to ensure the quality of blended fertilizers. According to this problem, the blended fertilizer equipment is researched: the equipment is novel in design and practical, it is mainly composed of lifting feeding system, high-precision mixing system, storage system rack, electric control system, etc. It can be self-flowing packaging, continuous production and other advantages.

-

Working Principle

-

- Commodity name: BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: Multiple materials

- Applications: Mixing of two or more fertilizers, premixes

BB fertilizer range mixer is widely applicable. Fertilizer/pharmaceutical/food/mining/dry powder BB fertilizer mixer has high mixing uniformity; it can make 1:10,000 times the proportion of materials mixed evenly, and its standard deviation is three parts per 100,000. BB fertilizer mixer has fast mixing speed and high efficiency. BB fertilizer mixer is fast and convenient, usually 2-5 minutes to finish a batch of material. BB fertilizer mixer mixing process is mild, smooth operation, low noise, basically not destroyed the original state of the material. To the phenomenon of material feeding, the mixing mechanism of the equipment is integral, reliable performance, all the angular welds rounded transition, easy to clean, lubrication Department parts are outside the barrel body without dripping oil and abrasive material infiltration into the material, can be sealed operation, isolated from the air dust into the material. Low energy consumption, large loading coefficient, filling coefficient of 0.7-0.9. Low requirements for the plant, the equipment is horizontal, and various forms of drive devices and discharge position can be arbitrarily selected, not subject to plant height, floor space constraints.

-

-

BB fertilizer mixer overcomes the phenomenon of mixing material lamination or diversion caused by the different specific gravity and granularity of raw materials, and improves the batching accuracy. It solves the influence on the system caused by material characteristics, mechanical vibration, air pressure, voltage fluctuation, cold weather, etc. It has the characteristics of high accuracy, fast speed and long service life, which is the ideal choice for BB fertilizer (blended fertilizer) manufacturers. The main equipment adopts forward and reverse operation, and the material is mixed and output by special internal spiral mechanism and unique three-dimensional structure. The whole set of equipment has the characteristics of low price, small footprint, large output and even mixing. After years of research, our company found that the general requirements of basic fertilizers are uniform particle size, low moisture content, good particle strength, no lumping in storage, and the consistency of the raw material fertilizers used for blended fertilizers, the consistency of particle size, not only requires the same value of the upper and lower limits of particle size, but also requires them to have similar particle size distribution, therefore, the analysis of particle size distribution of different raw materials before fertilizer blending is an important step to ensure the quality of blended fertilizers. According to this problem, the blended fertilizer equipment is researched: the equipment is novel in design and practical, it is mainly composed of lifting feeding system, high-precision mixing system, storage system rack, electric control system, etc. It can be self-flowing packaging, continuous production and other advantages.

-

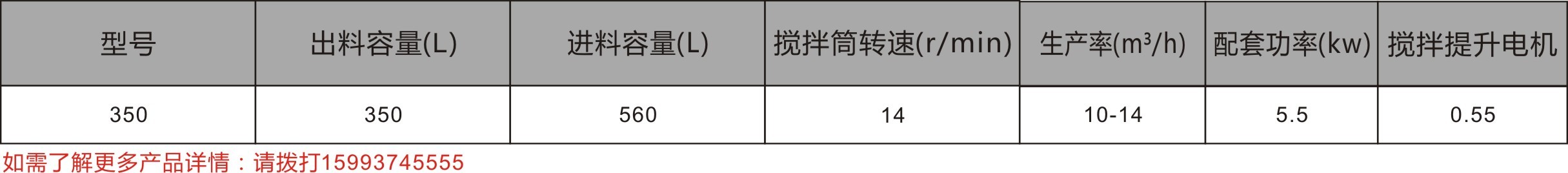

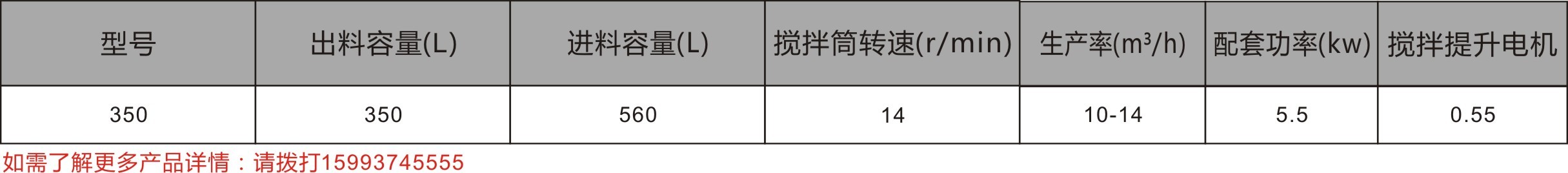

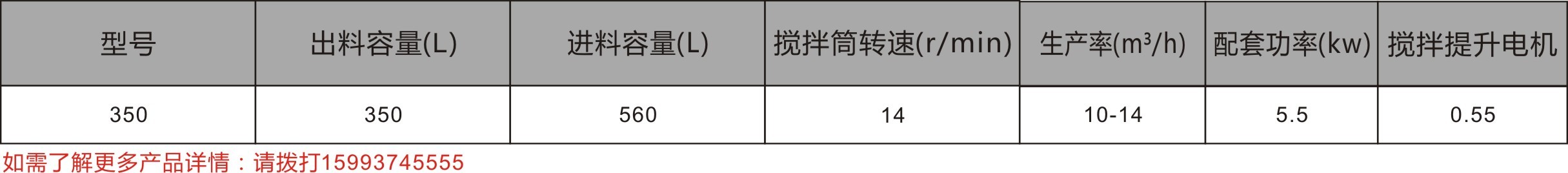

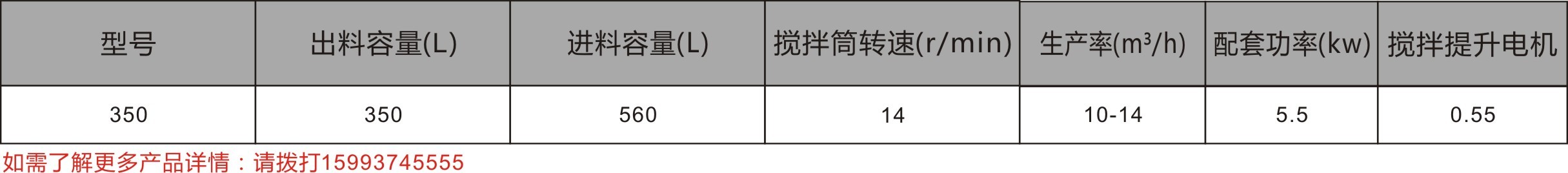

Technical parameters

-

- Commodity name: BB fertilizer mixer

- Production capacity: 5-8t/h

- Applicable materials: Multiple materials

- Applications: Mixing of two or more fertilizers, premixes

BB fertilizer range mixer is widely applicable. Fertilizer/pharmaceutical/food/mining/dry powder BB fertilizer mixer has high mixing uniformity; it can make 1:10,000 times the proportion of materials mixed evenly, and its standard deviation is three parts per 100,000. BB fertilizer mixer has fast mixing speed and high efficiency. BB fertilizer mixer is fast and convenient, usually 2-5 minutes to finish a batch of material. BB fertilizer mixer mixing process is mild, smooth operation, low noise, basically not destroyed the original state of the material. To the phenomenon of material feeding, the mixing mechanism of the equipment is integral, reliable performance, all the angular welds rounded transition, easy to clean, lubrication Department parts are outside the barrel body without dripping oil and abrasive material infiltration into the material, can be sealed operation, isolated from the air dust into the material. Low energy consumption, large loading coefficient, filling coefficient of 0.7-0.9. Low requirements for the plant, the equipment is horizontal, and various forms of drive devices and discharge position can be arbitrarily selected, not subject to plant height, floor space constraints.

-

-

BB fertilizer mixer overcomes the phenomenon of mixing material lamination or diversion caused by the different specific gravity and granularity of raw materials, and improves the batching accuracy. It solves the influence on the system caused by material characteristics, mechanical vibration, air pressure, voltage fluctuation, cold weather, etc. It has the characteristics of high accuracy, fast speed and long service life, which is the ideal choice for BB fertilizer (blended fertilizer) manufacturers. The main equipment adopts forward and reverse operation, and the material is mixed and output by special internal spiral mechanism and unique three-dimensional structure. The whole set of equipment has the characteristics of low price, small footprint, large output and even mixing. After years of research, our company found that the general requirements of basic fertilizers are uniform particle size, low moisture content, good particle strength, no lumping in storage, and the consistency of the raw material fertilizers used for blended fertilizers, the consistency of particle size, not only requires the same value of the upper and lower limits of particle size, but also requires them to have similar particle size distribution, therefore, the analysis of particle size distribution of different raw materials before fertilizer blending is an important step to ensure the quality of blended fertilizers. According to this problem, the blended fertilizer equipment is researched: the equipment is novel in design and practical, it is mainly composed of lifting feeding system, high-precision mixing system, storage system rack, electric control system, etc. It can be self-flowing packaging, continuous production and other advantages.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry