Introduction

-

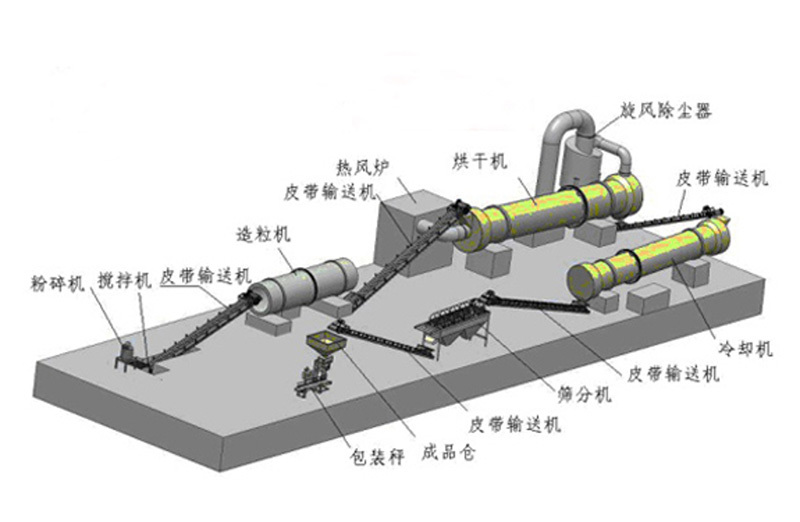

The process flow of compound fertilizer production line can usually be divided into: raw material ingredients → raw material mixing → raw material granulation → granule drying → granule cooling → granule classification → finished product wrapping → finished product packaging

-

Compound fertilizer production line with low investment, fast payback and good economic benefits. Complete set of equipment Ling Cheng layout is compact, scientific and reasonable, no three waste discharge, stable operation, reliable operation and convenient maintenance. Wide adaptability of raw materials, suitable for compound fertilizer, medicine, chemical, feed and other raw materials granulation, high product granulation rate. It can produce various concentrations and types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetized fertilizer, etc.) of compound fertilizer.

-

Compound fertilizer production line process

1, raw material ingredients: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, calcium), potassium chloride (potassium sulfate) and other raw materials in a certain proportion (according to market demand and soil test results around the world).

2、Mixing of raw materials: Mixing of the raw materials to improve the overall uniform fertilizer content of fertilizer granules.

3, granulation of raw materials: the mixing of raw materials into the granulator granulation (available drum granulator, can also choose to extrusion granulator).

4、Pellet drying: the granulator to make good particles sent to the dryer, the moisture contained in the particles will be dried to increase the strength of the particles, easy to save.

5, particle cooling: drying fertilizer particles are too high temperature, easy to clump, after cooling, easy to save in bags, and transport.

6、Granule grading: grading the cooled granules, unqualified granules are crushed and re-granulated, and the qualified products are sieved out.

7、Finished product film: the qualified products will be coated with film to increase the brightness and roundness of the particles.

8, Finished product packaging: the film wrapped particles that is the finished product bagged in a ventilated place for storage.

-

-Since the granules are chemically synthesized, the nutrient content of the granules is the same as the label, and they can provide ammonia, phosphorus, potassium and other nutrients to the crops at the same time in a certain proportion to ensure the balanced growth of the crops.

-The physical properties of the product are good. 90% of the granules are of 2-4 mm in size, with high strength and good fluidity, and are not easily broken during transportation, storage and stacking. The design is integrated with foreign advanced technology to further optimize the performance of the device design.

For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Compound fertilizer production line

The process flow of compound fertilizer production line can usually be divided into: raw material ingredients → raw material mixing → raw material granulation → granule drying → granule cooling → granule classification → finished product wrapping → finished product packaging

-

Compound fertilizer production line with low investment, fast payback and good economic benefits. Complete set of equipment Ling Cheng layout is compact, scientific and reasonable, no three waste discharge, stable operation, reliable operation and convenient maintenance. Wide adaptability of raw materials, suitable for compound fertilizer, medicine, chemical, feed and other raw materials granulation, high product granulation rate. It can produce various concentrations and types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetized fertilizer, etc.) of compound fertilizer.

-

Compound fertilizer production line process

1, raw material ingredients: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, calcium), potassium chloride (potassium sulfate) and other raw materials in a certain proportion (according to market demand and soil test results around the world).

2、Mixing of raw materials: Mixing of the raw materials to improve the overall uniform fertilizer content of fertilizer granules.

3, granulation of raw materials: the mixing of raw materials into the granulator granulation (available drum granulator, can also choose to extrusion granulator).

4、Pellet drying: the granulator to make good particles sent to the dryer, the moisture contained in the particles will be dried to increase the strength of the particles, easy to save.

5, particle cooling: drying fertilizer particles are too high temperature, easy to clump, after cooling, easy to save in bags, and transport.

6、Granule grading: grading the cooled granules, unqualified granules are crushed and re-granulated, and the qualified products are sieved out.

7、Finished product film: the qualified products will be coated with film to increase the brightness and roundness of the particles.

8, Finished product packaging: the film wrapped particles that is the finished product bagged in a ventilated place for storage.

-

-Since the granules are chemically synthesized, the nutrient content of the granules is the same as the label, and they can provide ammonia, phosphorus, potassium and other nutrients to the crops at the same time in a certain proportion to ensure the balanced growth of the crops.

-The physical properties of the product are good. 90% of the granules are of 2-4 mm in size, with high strength and good fluidity, and are not easily broken during transportation, storage and stacking. The design is integrated with foreign advanced technology to further optimize the performance of the device design.

For more product details: please call 15993745555

Working Principle

-

- Commodity name: Compound fertilizer production line

The process flow of compound fertilizer production line can usually be divided into: raw material ingredients → raw material mixing → raw material granulation → granule drying → granule cooling → granule classification → finished product wrapping → finished product packaging

-

Compound fertilizer production line with low investment, fast payback and good economic benefits. Complete set of equipment Ling Cheng layout is compact, scientific and reasonable, no three waste discharge, stable operation, reliable operation and convenient maintenance. Wide adaptability of raw materials, suitable for compound fertilizer, medicine, chemical, feed and other raw materials granulation, high product granulation rate. It can produce various concentrations and types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetized fertilizer, etc.) of compound fertilizer.

-

Compound fertilizer production line process

1, raw material ingredients: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, calcium), potassium chloride (potassium sulfate) and other raw materials in a certain proportion (according to market demand and soil test results around the world).

2、Mixing of raw materials: Mixing of the raw materials to improve the overall uniform fertilizer content of fertilizer granules.

3, granulation of raw materials: the mixing of raw materials into the granulator granulation (available drum granulator, can also choose to extrusion granulator).

4、Pellet drying: the granulator to make good particles sent to the dryer, the moisture contained in the particles will be dried to increase the strength of the particles, easy to save.

5, particle cooling: drying fertilizer particles are too high temperature, easy to clump, after cooling, easy to save in bags, and transport.

6、Granule grading: grading the cooled granules, unqualified granules are crushed and re-granulated, and the qualified products are sieved out.

7、Finished product film: the qualified products will be coated with film to increase the brightness and roundness of the particles.

8, Finished product packaging: the film wrapped particles that is the finished product bagged in a ventilated place for storage.

-

-Since the granules are chemically synthesized, the nutrient content of the granules is the same as the label, and they can provide ammonia, phosphorus, potassium and other nutrients to the crops at the same time in a certain proportion to ensure the balanced growth of the crops.

-The physical properties of the product are good. 90% of the granules are of 2-4 mm in size, with high strength and good fluidity, and are not easily broken during transportation, storage and stacking. The design is integrated with foreign advanced technology to further optimize the performance of the device design.

For more product details: please call 15993745555

Technical parameters

-

- Commodity name: Compound fertilizer production line

The process flow of compound fertilizer production line can usually be divided into: raw material ingredients → raw material mixing → raw material granulation → granule drying → granule cooling → granule classification → finished product wrapping → finished product packaging

-

Compound fertilizer production line with low investment, fast payback and good economic benefits. Complete set of equipment Ling Cheng layout is compact, scientific and reasonable, no three waste discharge, stable operation, reliable operation and convenient maintenance. Wide adaptability of raw materials, suitable for compound fertilizer, medicine, chemical, feed and other raw materials granulation, high product granulation rate. It can produce various concentrations and types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetized fertilizer, etc.) of compound fertilizer.

-

Compound fertilizer production line process

1, raw material ingredients: urea, ammonium nitrate, ammonium chloride, ammonium sulfate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, calcium), potassium chloride (potassium sulfate) and other raw materials in a certain proportion (according to market demand and soil test results around the world).

2、Mixing of raw materials: Mixing of the raw materials to improve the overall uniform fertilizer content of fertilizer granules.

3, granulation of raw materials: the mixing of raw materials into the granulator granulation (available drum granulator, can also choose to extrusion granulator).

4、Pellet drying: the granulator to make good particles sent to the dryer, the moisture contained in the particles will be dried to increase the strength of the particles, easy to save.

5, particle cooling: drying fertilizer particles are too high temperature, easy to clump, after cooling, easy to save in bags, and transport.

6、Granule grading: grading the cooled granules, unqualified granules are crushed and re-granulated, and the qualified products are sieved out.

7、Finished product film: the qualified products will be coated with film to increase the brightness and roundness of the particles.

8, Finished product packaging: the film wrapped particles that is the finished product bagged in a ventilated place for storage.

-

-Since the granules are chemically synthesized, the nutrient content of the granules is the same as the label, and they can provide ammonia, phosphorus, potassium and other nutrients to the crops at the same time in a certain proportion to ensure the balanced growth of the crops.

-The physical properties of the product are good. 90% of the granules are of 2-4 mm in size, with high strength and good fluidity, and are not easily broken during transportation, storage and stacking. The design is integrated with foreign advanced technology to further optimize the performance of the device design.

For more product details: please call 15993745555

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry