Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, organic fertilizer, inorganic fertilizer, fresh chicken, pig, cow dung, sludge, etc.

- Applications: The disc granulator is widely used in the processing of bio-organic fertilizer spherical particles, such as coal powder, cement, clinker, fertilizer and other materials。

Classification:

Tel:

Introduction

-

The disc granulator (also known as the ball-forming disc) is the raw material equipment for volumetric metering, which can evenly and continuously feed the material to the next process.

And can withstand large warehouse pressure. As a feeding equipment for fine-grained materials, it is suitable for conveying various non-viscous materials in powder, material or small pieces.

Materials, such as powdered, granular or small block materials such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay, etc.

The granulating disc angle of the disc granulator adopts an overall arc structure, and the granulation rate can reach more than 93%. The granulating disc is equipped with three discharge ports, which is convenient for intermittent production operations, greatly reduces labor intensity, and improves labor efficiency.

The bottom of the granulation pan is reinforced with a number of radiant steel plates, which are durable and not deformed. Heavy, thick and sturdy base design, no need for anchor bolts, and stable operation. The main gear of the granulator adopts high-frequency quenching, and the service life is doubled. The granulated face plate is lined with high-strength glass fiber reinforced plastic, which is anti-corrosion and durable. This surface has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment and long service life. It is an ideal equipment for the majority of users. -

The raw meal powder is mixed evenly by pre-adding water, and is input into the pan. With the rotation of the pan, the raw meal gradually forms a spherical shape by rolling in the pan body, reaching the predetermined level.

The diameter is discharged out of the tray, and then transported to the next process. -

Finished pellets

undefined

Features

-

- Commodity name: Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, organic fertilizer, inorganic fertilizer, fresh chicken, pig, cow dung, sludge, etc.

- Applications: The disc granulator is widely used in the processing of bio-organic fertilizer spherical particles, such as coal powder, cement, clinker, fertilizer and other materials。

The disc granulator (also known as the ball-forming disc) is the raw material equipment for volumetric metering, which can evenly and continuously feed the material to the next process.

And can withstand large warehouse pressure. As a feeding equipment for fine-grained materials, it is suitable for conveying various non-viscous materials in powder, material or small pieces.

Materials, such as powdered, granular or small block materials such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay, etc.

The granulating disc angle of the disc granulator adopts an overall arc structure, and the granulation rate can reach more than 93%. The granulating disc is equipped with three discharge ports, which is convenient for intermittent production operations, greatly reduces labor intensity, and improves labor efficiency.

The bottom of the granulation pan is reinforced with a number of radiant steel plates, which are durable and not deformed. Heavy, thick and sturdy base design, no need for anchor bolts, and stable operation. The main gear of the granulator adopts high-frequency quenching, and the service life is doubled. The granulated face plate is lined with high-strength glass fiber reinforced plastic, which is anti-corrosion and durable. This surface has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment and long service life. It is an ideal equipment for the majority of users. -

The raw meal powder is mixed evenly by pre-adding water, and is input into the pan. With the rotation of the pan, the raw meal gradually forms a spherical shape by rolling in the pan body, reaching the predetermined level.

The diameter is discharged out of the tray, and then transported to the next process. -

Working Principle

-

- Commodity name: Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, organic fertilizer, inorganic fertilizer, fresh chicken, pig, cow dung, sludge, etc.

- Applications: The disc granulator is widely used in the processing of bio-organic fertilizer spherical particles, such as coal powder, cement, clinker, fertilizer and other materials。

The disc granulator (also known as the ball-forming disc) is the raw material equipment for volumetric metering, which can evenly and continuously feed the material to the next process.

And can withstand large warehouse pressure. As a feeding equipment for fine-grained materials, it is suitable for conveying various non-viscous materials in powder, material or small pieces.

Materials, such as powdered, granular or small block materials such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay, etc.

The granulating disc angle of the disc granulator adopts an overall arc structure, and the granulation rate can reach more than 93%. The granulating disc is equipped with three discharge ports, which is convenient for intermittent production operations, greatly reduces labor intensity, and improves labor efficiency.

The bottom of the granulation pan is reinforced with a number of radiant steel plates, which are durable and not deformed. Heavy, thick and sturdy base design, no need for anchor bolts, and stable operation. The main gear of the granulator adopts high-frequency quenching, and the service life is doubled. The granulated face plate is lined with high-strength glass fiber reinforced plastic, which is anti-corrosion and durable. This surface has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment and long service life. It is an ideal equipment for the majority of users. -

The raw meal powder is mixed evenly by pre-adding water, and is input into the pan. With the rotation of the pan, the raw meal gradually forms a spherical shape by rolling in the pan body, reaching the predetermined level.

The diameter is discharged out of the tray, and then transported to the next process. -

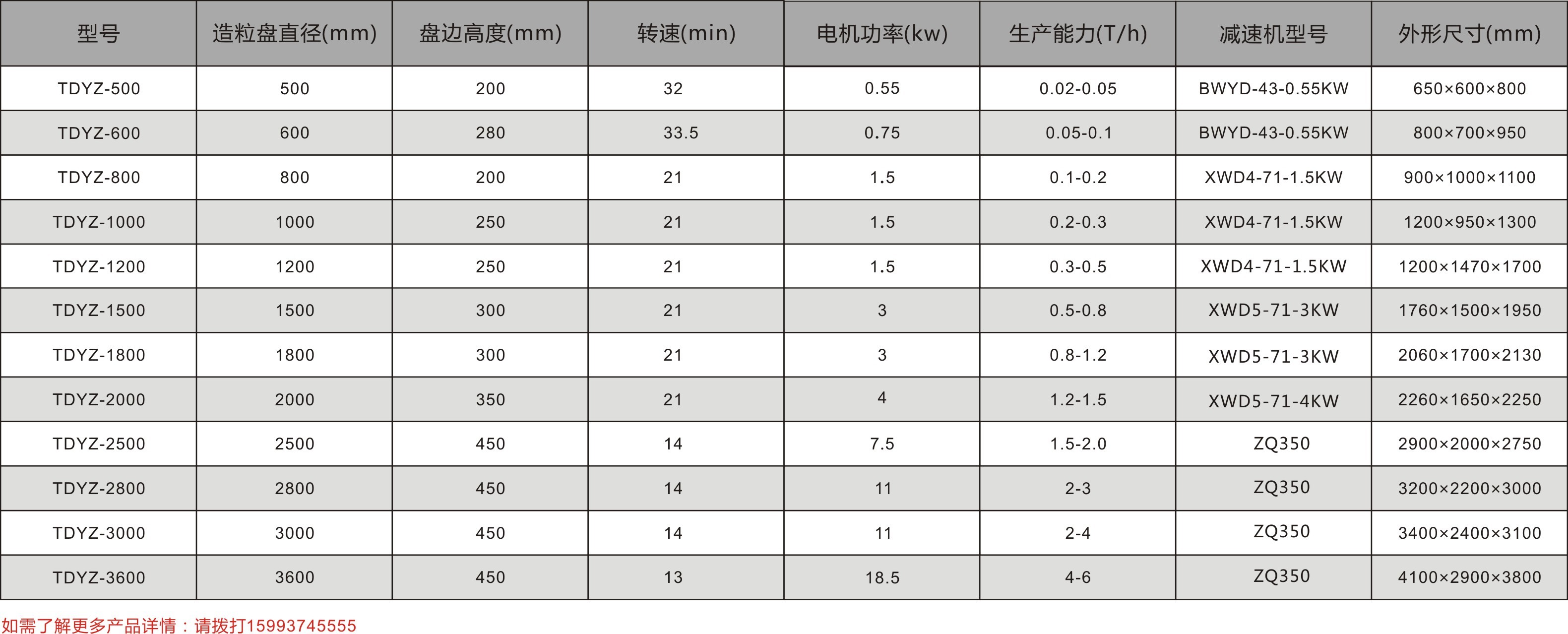

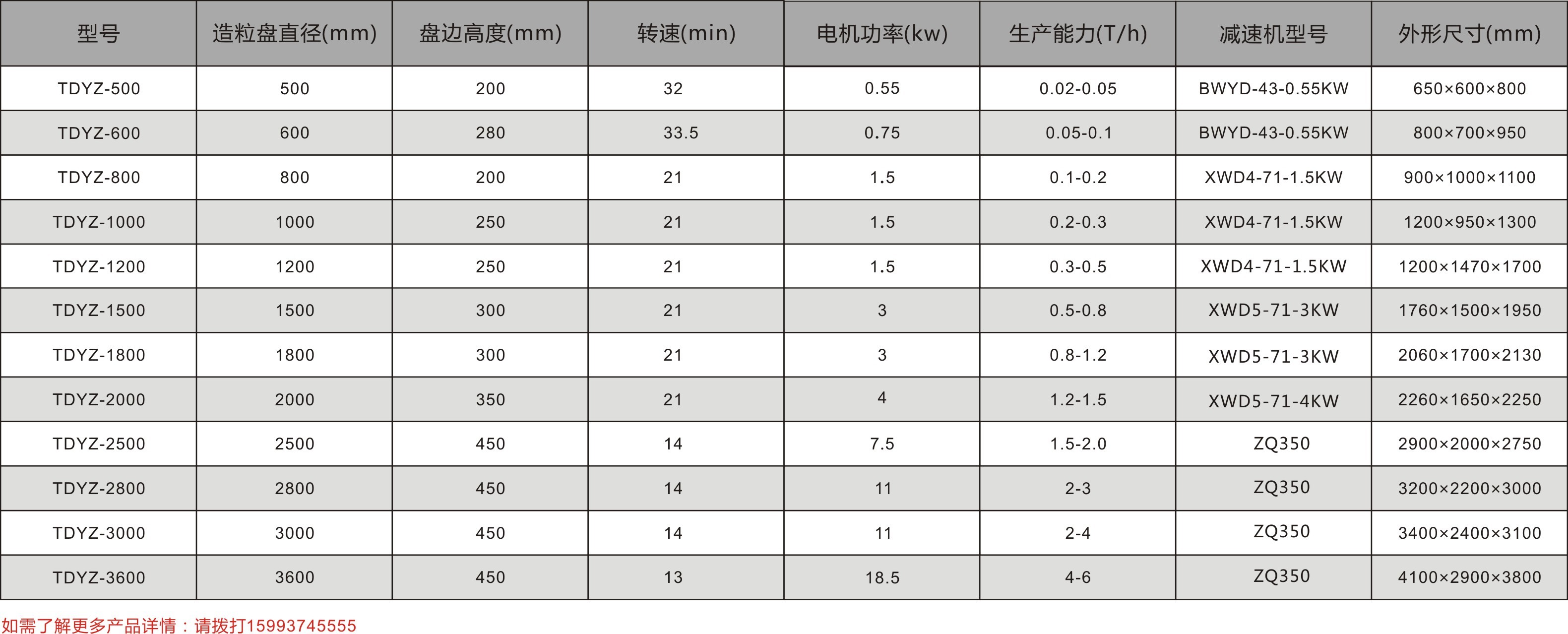

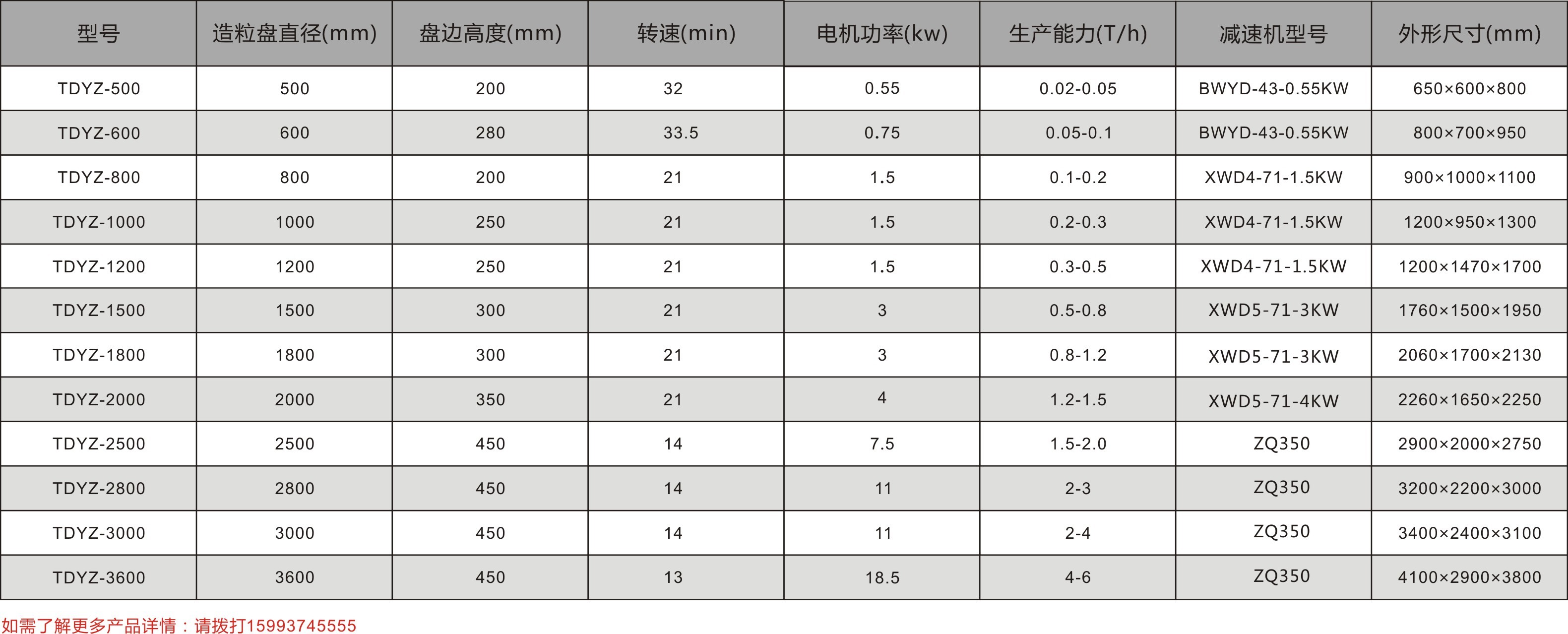

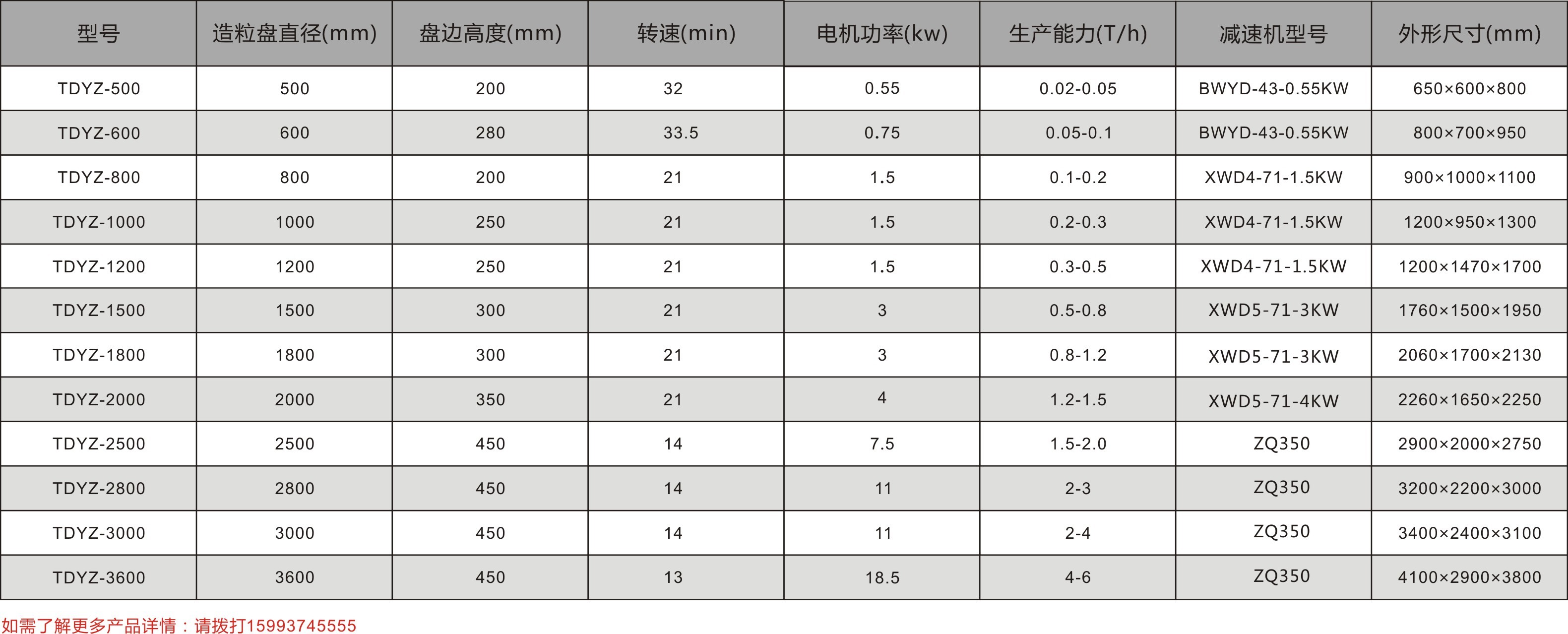

Technical parameters

-

- Commodity name: Disc granulator

- Production capacity: 0.02 to 6 tons/hour

- Applicable materials: Fertilizer, municipal waste, organic fertilizer, inorganic fertilizer, fresh chicken, pig, cow dung, sludge, etc.

- Applications: The disc granulator is widely used in the processing of bio-organic fertilizer spherical particles, such as coal powder, cement, clinker, fertilizer and other materials。

The disc granulator (also known as the ball-forming disc) is the raw material equipment for volumetric metering, which can evenly and continuously feed the material to the next process.

And can withstand large warehouse pressure. As a feeding equipment for fine-grained materials, it is suitable for conveying various non-viscous materials in powder, material or small pieces.

Materials, such as powdered, granular or small block materials such as pulverized coal, cement, clinker, limestone, shale, coal gangue, clay, etc.

The granulating disc angle of the disc granulator adopts an overall arc structure, and the granulation rate can reach more than 93%. The granulating disc is equipped with three discharge ports, which is convenient for intermittent production operations, greatly reduces labor intensity, and improves labor efficiency.

The bottom of the granulation pan is reinforced with a number of radiant steel plates, which are durable and not deformed. Heavy, thick and sturdy base design, no need for anchor bolts, and stable operation. The main gear of the granulator adopts high-frequency quenching, and the service life is doubled. The granulated face plate is lined with high-strength glass fiber reinforced plastic, which is anti-corrosion and durable. This surface has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment and long service life. It is an ideal equipment for the majority of users. -

The raw meal powder is mixed evenly by pre-adding water, and is input into the pan. With the rotation of the pan, the raw meal gradually forms a spherical shape by rolling in the pan body, reaching the predetermined level.

The diameter is discharged out of the tray, and then transported to the next process. -

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry