Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials: Mainly suitable for coarse fiber granulation, such as: wood chips, rice husk, cotton stalk, cotton seed bark, weeds and other kinds of crop straw, household garbage, waste plastics and factories

- Applications: Mainly used for pellet processing in the (bio)organic fertilizer and aquaculture processing industries

Classification:

Tel:

Introduction

-

The machine is one of the main (bio)organic fertilizer production equipment produced at present, is our factory scientific and technical personnel set at home and abroad on the basis of the granule machine, with many years of production experience repeated research, improvement, carefully manufactured fertilizer machinery, the machine has excellent technology, simple operation, and designed with different models of a variety of models, fertilizer processing unit ideal processing machinery.

1, the machine is mainly used for (biological) organic fertilizer and farming processing industry particle pulling processing;

2, the machine processed granular material surface clean, moderate hardness, low temperature rise in the processing process and can better maintain the internal nutrients of raw materials;

3, The granule is even in composition and neat in shape, and the aperture of the granule can be divided into Φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to their production needs when ordering;

4, It is easy to store the granule because of its low water content, and it can keep its original shape in water for a long time, which can greatly improve the utilization rate of the material.

-

1、Add double curve gear oil in the gearbox before you can start the machine;

2, the pellet machine will be installed smoothly, adjust the belt elasticity, steering is normal, all parts of the screw is not loose imagine relaxing the roller shaft seat on the adjustment gap screw, so that the machine is in a state of no load start normal after you can put into use;

3, the first use of the new machine, take 10 pounds of grass powder (or sawdust) fine sand 2 pounds plus (about 1.5 kg) vegetable oil or waste oil (note; can also be used in place of a larger amount of oil abrasive material) stir well, twist the gap adjusting screw to the roller and template gap of 0.1-0.3 mm, so that the speed of the two pressure rollers are the same, gradually add the material with oil, squeeze the particles repeatedly zap squeeze, so that the membrane hole lubrication smooth and then slowly add the required mixture of materials for processing such as Need to process the mixture of materials for processing such as feeling the membrane hole resistance, low yield or not out of material can be repeatedly grinding the membrane plate according to the above method, so that the membrane hole lubrication smoothly before processing;

4, in the material processing such as fine fiber more, should add about 5% of water, such as the mixture of fine fiber more can reduce the amount of water added, the water in the extrusion process will play off;

5、After processing, relax the gap adjusting screw. Make the roller in a free state, after the shutdown to clear the upper and lower bin material accumulation of dirt, especially with the remaining material under the plate, in order to avoid damage to the bearings.

-

Finished pellets

undefined

Features

-

- Commodity name: Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials: Mainly suitable for coarse fiber granulation, such as: wood chips, rice husk, cotton stalk, cotton seed bark, weeds and other kinds of crop straw, household garbage, waste plastics and factories

- Applications: Mainly used for pellet processing in the (bio)organic fertilizer and aquaculture processing industries

The machine is one of the main (bio)organic fertilizer production equipment produced at present, is our factory scientific and technical personnel set at home and abroad on the basis of the granule machine, with many years of production experience repeated research, improvement, carefully manufactured fertilizer machinery, the machine has excellent technology, simple operation, and designed with different models of a variety of models, fertilizer processing unit ideal processing machinery.

1, the machine is mainly used for (biological) organic fertilizer and farming processing industry particle pulling processing;

2, the machine processed granular material surface clean, moderate hardness, low temperature rise in the processing process and can better maintain the internal nutrients of raw materials;

3, The granule is even in composition and neat in shape, and the aperture of the granule can be divided into Φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to their production needs when ordering;

4, It is easy to store the granule because of its low water content, and it can keep its original shape in water for a long time, which can greatly improve the utilization rate of the material.

-

1、Add double curve gear oil in the gearbox before you can start the machine;

2, the pellet machine will be installed smoothly, adjust the belt elasticity, steering is normal, all parts of the screw is not loose imagine relaxing the roller shaft seat on the adjustment gap screw, so that the machine is in a state of no load start normal after you can put into use;

3, the first use of the new machine, take 10 pounds of grass powder (or sawdust) fine sand 2 pounds plus (about 1.5 kg) vegetable oil or waste oil (note; can also be used in place of a larger amount of oil abrasive material) stir well, twist the gap adjusting screw to the roller and template gap of 0.1-0.3 mm, so that the speed of the two pressure rollers are the same, gradually add the material with oil, squeeze the particles repeatedly zap squeeze, so that the membrane hole lubrication smooth and then slowly add the required mixture of materials for processing such as Need to process the mixture of materials for processing such as feeling the membrane hole resistance, low yield or not out of material can be repeatedly grinding the membrane plate according to the above method, so that the membrane hole lubrication smoothly before processing;

4, in the material processing such as fine fiber more, should add about 5% of water, such as the mixture of fine fiber more can reduce the amount of water added, the water in the extrusion process will play off;

5、After processing, relax the gap adjusting screw. Make the roller in a free state, after the shutdown to clear the upper and lower bin material accumulation of dirt, especially with the remaining material under the plate, in order to avoid damage to the bearings.

-

Working Principle

-

- Commodity name: Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials: Mainly suitable for coarse fiber granulation, such as: wood chips, rice husk, cotton stalk, cotton seed bark, weeds and other kinds of crop straw, household garbage, waste plastics and factories

- Applications: Mainly used for pellet processing in the (bio)organic fertilizer and aquaculture processing industries

The machine is one of the main (bio)organic fertilizer production equipment produced at present, is our factory scientific and technical personnel set at home and abroad on the basis of the granule machine, with many years of production experience repeated research, improvement, carefully manufactured fertilizer machinery, the machine has excellent technology, simple operation, and designed with different models of a variety of models, fertilizer processing unit ideal processing machinery.

1, the machine is mainly used for (biological) organic fertilizer and farming processing industry particle pulling processing;

2, the machine processed granular material surface clean, moderate hardness, low temperature rise in the processing process and can better maintain the internal nutrients of raw materials;

3, The granule is even in composition and neat in shape, and the aperture of the granule can be divided into Φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to their production needs when ordering;

4, It is easy to store the granule because of its low water content, and it can keep its original shape in water for a long time, which can greatly improve the utilization rate of the material.

-

1、Add double curve gear oil in the gearbox before you can start the machine;

2, the pellet machine will be installed smoothly, adjust the belt elasticity, steering is normal, all parts of the screw is not loose imagine relaxing the roller shaft seat on the adjustment gap screw, so that the machine is in a state of no load start normal after you can put into use;

3, the first use of the new machine, take 10 pounds of grass powder (or sawdust) fine sand 2 pounds plus (about 1.5 kg) vegetable oil or waste oil (note; can also be used in place of a larger amount of oil abrasive material) stir well, twist the gap adjusting screw to the roller and template gap of 0.1-0.3 mm, so that the speed of the two pressure rollers are the same, gradually add the material with oil, squeeze the particles repeatedly zap squeeze, so that the membrane hole lubrication smooth and then slowly add the required mixture of materials for processing such as Need to process the mixture of materials for processing such as feeling the membrane hole resistance, low yield or not out of material can be repeatedly grinding the membrane plate according to the above method, so that the membrane hole lubrication smoothly before processing;

4, in the material processing such as fine fiber more, should add about 5% of water, such as the mixture of fine fiber more can reduce the amount of water added, the water in the extrusion process will play off;

5、After processing, relax the gap adjusting screw. Make the roller in a free state, after the shutdown to clear the upper and lower bin material accumulation of dirt, especially with the remaining material under the plate, in order to avoid damage to the bearings.

-

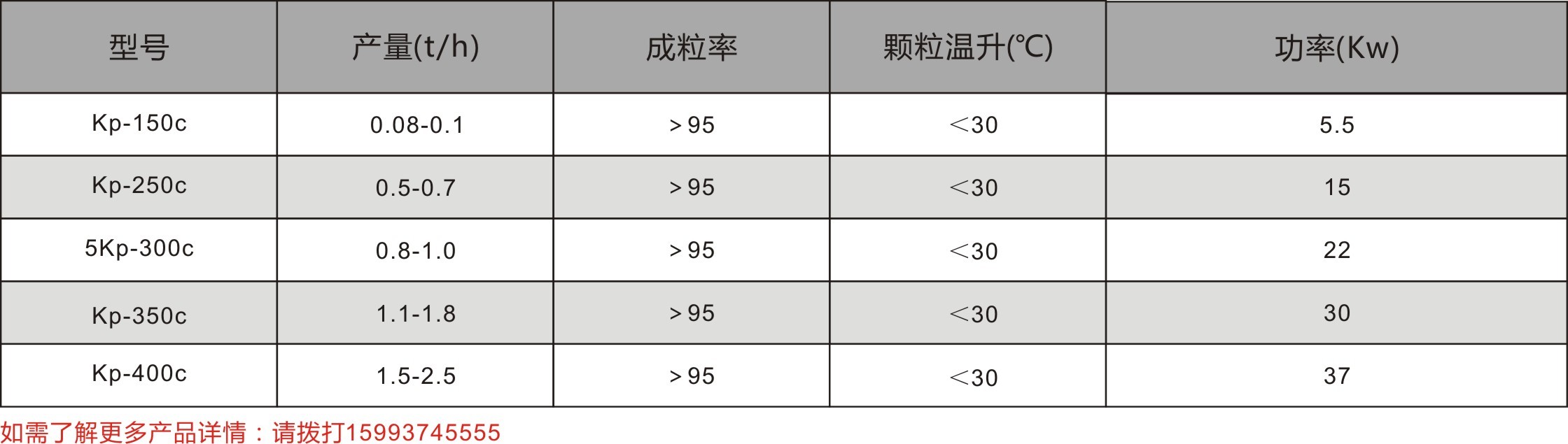

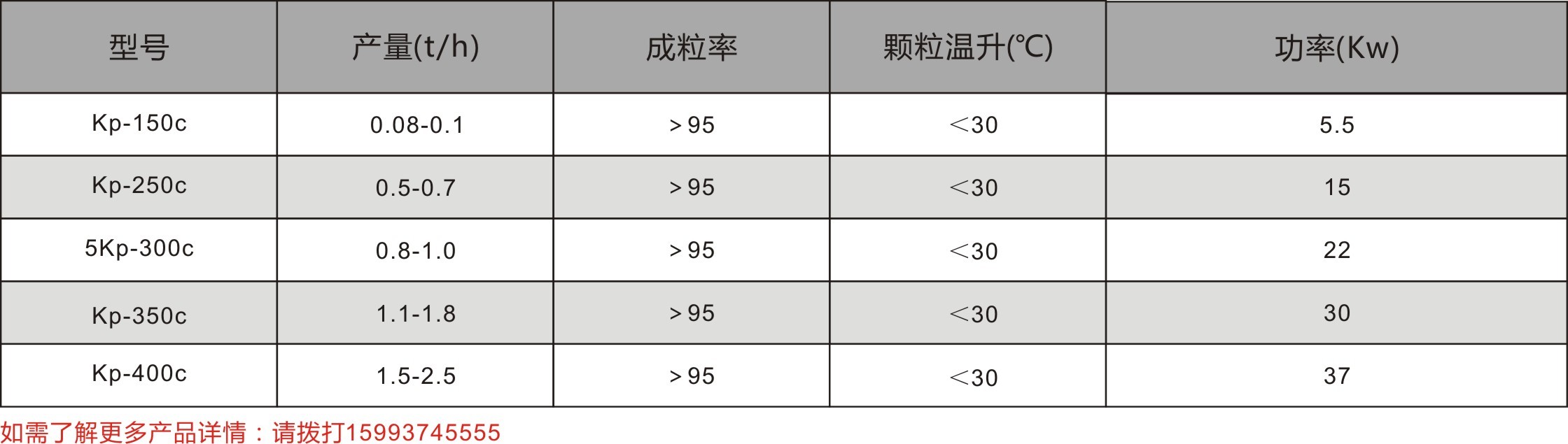

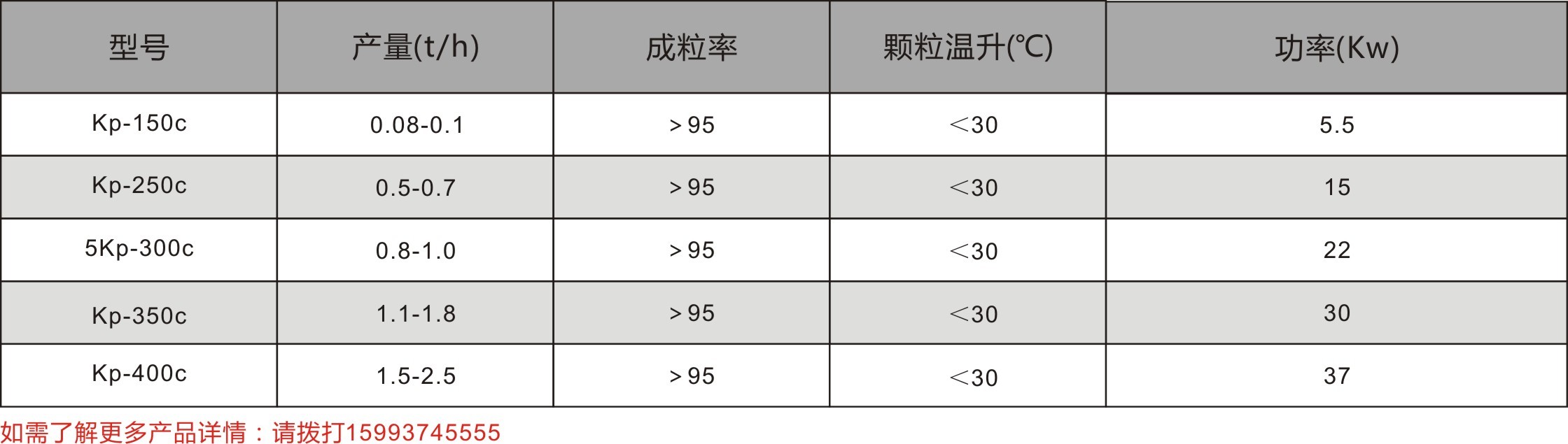

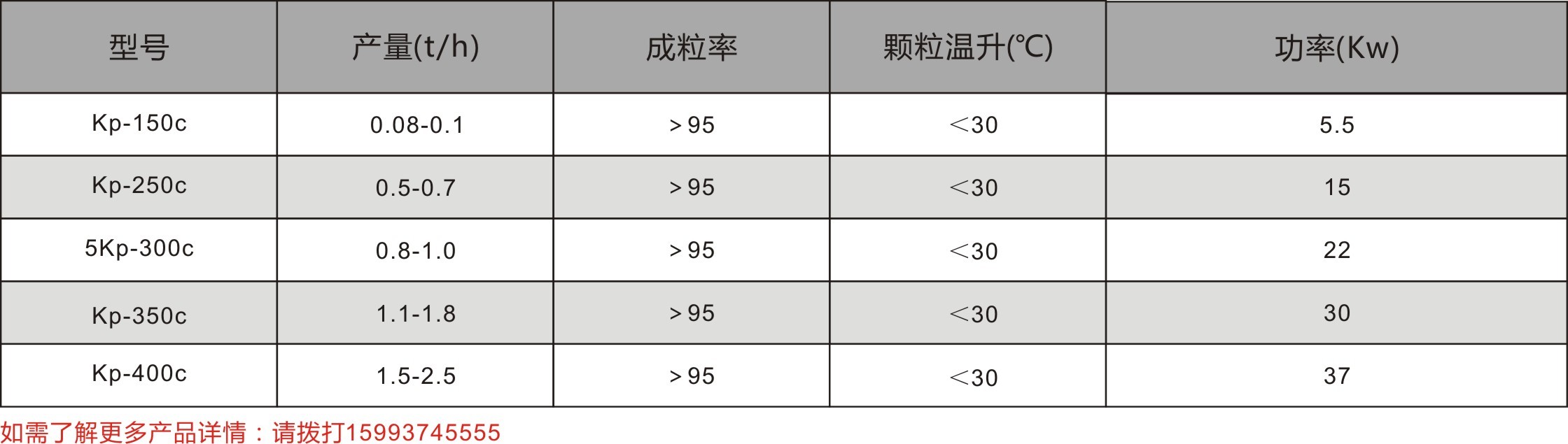

Technical parameters

-

- Commodity name: Flat Mill Granulator

- Production capacity: 0.08-2.5 tons per hour

- Applicable materials: Mainly suitable for coarse fiber granulation, such as: wood chips, rice husk, cotton stalk, cotton seed bark, weeds and other kinds of crop straw, household garbage, waste plastics and factories

- Applications: Mainly used for pellet processing in the (bio)organic fertilizer and aquaculture processing industries

The machine is one of the main (bio)organic fertilizer production equipment produced at present, is our factory scientific and technical personnel set at home and abroad on the basis of the granule machine, with many years of production experience repeated research, improvement, carefully manufactured fertilizer machinery, the machine has excellent technology, simple operation, and designed with different models of a variety of models, fertilizer processing unit ideal processing machinery.

1, the machine is mainly used for (biological) organic fertilizer and farming processing industry particle pulling processing;

2, the machine processed granular material surface clean, moderate hardness, low temperature rise in the processing process and can better maintain the internal nutrients of raw materials;

3, The granule is even in composition and neat in shape, and the aperture of the granule can be divided into Φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to their production needs when ordering;

4, It is easy to store the granule because of its low water content, and it can keep its original shape in water for a long time, which can greatly improve the utilization rate of the material.

-

1、Add double curve gear oil in the gearbox before you can start the machine;

2, the pellet machine will be installed smoothly, adjust the belt elasticity, steering is normal, all parts of the screw is not loose imagine relaxing the roller shaft seat on the adjustment gap screw, so that the machine is in a state of no load start normal after you can put into use;

3, the first use of the new machine, take 10 pounds of grass powder (or sawdust) fine sand 2 pounds plus (about 1.5 kg) vegetable oil or waste oil (note; can also be used in place of a larger amount of oil abrasive material) stir well, twist the gap adjusting screw to the roller and template gap of 0.1-0.3 mm, so that the speed of the two pressure rollers are the same, gradually add the material with oil, squeeze the particles repeatedly zap squeeze, so that the membrane hole lubrication smooth and then slowly add the required mixture of materials for processing such as Need to process the mixture of materials for processing such as feeling the membrane hole resistance, low yield or not out of material can be repeatedly grinding the membrane plate according to the above method, so that the membrane hole lubrication smoothly before processing;

4, in the material processing such as fine fiber more, should add about 5% of water, such as the mixture of fine fiber more can reduce the amount of water added, the water in the extrusion process will play off;

5、After processing, relax the gap adjusting screw. Make the roller in a free state, after the shutdown to clear the upper and lower bin material accumulation of dirt, especially with the remaining material under the plate, in order to avoid damage to the bearings.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry