Cow Dung Organic Fertilizer

- Production capacity: Annual output of 10,000-200,000 tons of cow dung organic fertilizer

- Applicable materials: Cow dung, etc.

- Applications: Production of cow dung organic fertilizer, etc.

Classification:

Tel:

Introduction

-

The cow dung organic fertilizer production line is a complete set of equipment for processing organic fertilizer from cow dung. The cow dung processing machine can be used to pump the cow dung in the manure pond to the equipment through the mud pump, and then it can be dehydrated by the equipment. % or so, crops such as straw and rice bran (including N\P\K) can also be used as fillers, and then sprinkle with biological inoculum, and 1KG of inoculum is mixed with 20KG of water and moved into the raw materials, which can ferment 1 ton of raw materials. Turn and toss once every 1-2 days, generally 7-10 days can be completely decomposed. Small investment, quick return on capital, closer

The pollution of livestock and poultry manure and the residues of livestock and poultry products poses a problem to human health. Pollution from livestock and poultry farming has become a major source of pollution in rural China. The huge data of livestock and poultry production cannot but be paid attention to, if not handled properly, it will cause serious pollution to the environment. For example, because livestock and poultry manure is not treated in time, it will cause serious pollution to surface water, groundwater, soil and air. More seriously, for the convenience of transportation, small-scale farmers simply pile up the dung of beef cattle.

Put it next to the road without taking a scientific storage method. Due to neglect of management, wind and rain make feces flow everywhere. Such a situation is not conducive to the requirements of animal epidemic prevention, and will certainly have a certain impact on people's living environment.

-

Organic fertilizer production line equipment, the process layout is compact, scientific and reasonable, no three emissions, stable operation, reliable operation, convenient maintenance, and wide adaptability of raw materials. Organic compound fertilizers, bio-organic fertilizers, urban sludge, and domestic waste organic fertilizers that adapt to various ratios are the promotion projects of national environmental protection practical technologies. Cow dung is rich in organic matter, which can provide nutrients for crop growth and fertilize. Improve soil. There are many kinds of organic fertilizers, the raw materials are very wide, and the fertilizers are also ever-changing.

-

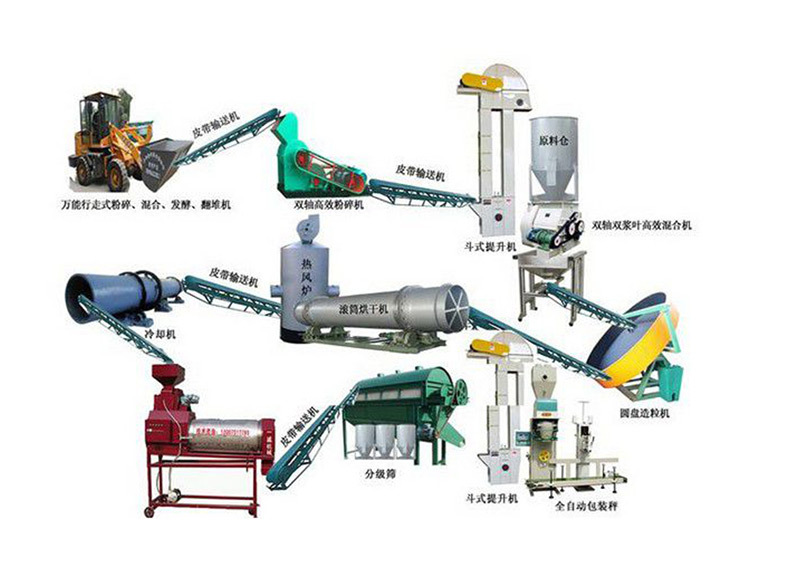

The organic fertilizer production process is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete set of equipment for the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system, cooling and drying system, It consists of a screening system and a finished product packaging system. The equipment requirements of each link system of the organic fertilizer production process are described in detail below: the fermentation system of the organic fertilizer production process consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary liter

It is composed of a drop-type turning and polishing machine and an electrical automatic control system; the main equipment of the drying system is a belt conveyor, a rotary drum dryer, a cooler, an induced draft fan, a hot blast furnace, etc.; the deodorization and dust removal system is composed of a sedimentation chamber, a dust removal chamber, etc. , Hengmu Machinery provides free drawings and guides users to build for free; the crushing system includes new semi-wet material crushers, chain crushers or cage crushers, belt conveyors, etc. The batching system includes electronic batching systems, Disc feeder, vibrating screen, can configure 6-8 at a time

raw materials, etc.;

The mixing system consists of optional horizontal mixers or disc mixers, vibrating screens, mobile belt conveyors, etc. The granulation system of the organic fertilizer production process needs to use granulator equipment, and the optional granulator equipment includes: : Compound fertilizer counter-rolling extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, organic fertilizer special granulator,

Rotary drum granulator, rounding machine, compound fertilizer special granulator, etc. The cooling and drying system can be used for rotary dryer, rotary drum cooler and other equipment for drying and cooling. The screening system is mainly completed by a trommel screening machine, and a primary screening machine and a secondary screening machine can be set up to make the finished product rate higher and the particles better; the finished product packaging system generally includes electronic quantitative packaging scales, silos, automatic sewing machines, etc. . In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized.

-

For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Cow Dung Organic Fertilizer

- Production capacity: Annual output of 10,000-200,000 tons of cow dung organic fertilizer

- Applicable materials: Cow dung, etc.

- Applications: Production of cow dung organic fertilizer, etc.

The cow dung organic fertilizer production line is a complete set of equipment for processing organic fertilizer from cow dung. The cow dung processing machine can be used to pump the cow dung in the manure pond to the equipment through the mud pump, and then it can be dehydrated by the equipment. % or so, crops such as straw and rice bran (including N\P\K) can also be used as fillers, and then sprinkle with biological inoculum, and 1KG of inoculum is mixed with 20KG of water and moved into the raw materials, which can ferment 1 ton of raw materials. Turn and toss once every 1-2 days, generally 7-10 days can be completely decomposed. Small investment, quick return on capital, closer

The pollution of livestock and poultry manure and the residues of livestock and poultry products poses a problem to human health. Pollution from livestock and poultry farming has become a major source of pollution in rural China. The huge data of livestock and poultry production cannot but be paid attention to, if not handled properly, it will cause serious pollution to the environment. For example, because livestock and poultry manure is not treated in time, it will cause serious pollution to surface water, groundwater, soil and air. More seriously, for the convenience of transportation, small-scale farmers simply pile up the dung of beef cattle.

Put it next to the road without taking a scientific storage method. Due to neglect of management, wind and rain make feces flow everywhere. Such a situation is not conducive to the requirements of animal epidemic prevention, and will certainly have a certain impact on people's living environment.

-

Organic fertilizer production line equipment, the process layout is compact, scientific and reasonable, no three emissions, stable operation, reliable operation, convenient maintenance, and wide adaptability of raw materials. Organic compound fertilizers, bio-organic fertilizers, urban sludge, and domestic waste organic fertilizers that adapt to various ratios are the promotion projects of national environmental protection practical technologies. Cow dung is rich in organic matter, which can provide nutrients for crop growth and fertilize. Improve soil. There are many kinds of organic fertilizers, the raw materials are very wide, and the fertilizers are also ever-changing.

-

The organic fertilizer production process is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete set of equipment for the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system, cooling and drying system, It consists of a screening system and a finished product packaging system. The equipment requirements of each link system of the organic fertilizer production process are described in detail below: the fermentation system of the organic fertilizer production process consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary liter

It is composed of a drop-type turning and polishing machine and an electrical automatic control system; the main equipment of the drying system is a belt conveyor, a rotary drum dryer, a cooler, an induced draft fan, a hot blast furnace, etc.; the deodorization and dust removal system is composed of a sedimentation chamber, a dust removal chamber, etc. , Hengmu Machinery provides free drawings and guides users to build for free; the crushing system includes new semi-wet material crushers, chain crushers or cage crushers, belt conveyors, etc. The batching system includes electronic batching systems, Disc feeder, vibrating screen, can configure 6-8 at a time

raw materials, etc.;

The mixing system consists of optional horizontal mixers or disc mixers, vibrating screens, mobile belt conveyors, etc. The granulation system of the organic fertilizer production process needs to use granulator equipment, and the optional granulator equipment includes: : Compound fertilizer counter-rolling extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, organic fertilizer special granulator,

Rotary drum granulator, rounding machine, compound fertilizer special granulator, etc. The cooling and drying system can be used for rotary dryer, rotary drum cooler and other equipment for drying and cooling. The screening system is mainly completed by a trommel screening machine, and a primary screening machine and a secondary screening machine can be set up to make the finished product rate higher and the particles better; the finished product packaging system generally includes electronic quantitative packaging scales, silos, automatic sewing machines, etc. . In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized.

-

For more product details: please call 15993745555

Working Principle

-

- Commodity name: Cow Dung Organic Fertilizer

- Production capacity: Annual output of 10,000-200,000 tons of cow dung organic fertilizer

- Applicable materials: Cow dung, etc.

- Applications: Production of cow dung organic fertilizer, etc.

The cow dung organic fertilizer production line is a complete set of equipment for processing organic fertilizer from cow dung. The cow dung processing machine can be used to pump the cow dung in the manure pond to the equipment through the mud pump, and then it can be dehydrated by the equipment. % or so, crops such as straw and rice bran (including N\P\K) can also be used as fillers, and then sprinkle with biological inoculum, and 1KG of inoculum is mixed with 20KG of water and moved into the raw materials, which can ferment 1 ton of raw materials. Turn and toss once every 1-2 days, generally 7-10 days can be completely decomposed. Small investment, quick return on capital, closer

The pollution of livestock and poultry manure and the residues of livestock and poultry products poses a problem to human health. Pollution from livestock and poultry farming has become a major source of pollution in rural China. The huge data of livestock and poultry production cannot but be paid attention to, if not handled properly, it will cause serious pollution to the environment. For example, because livestock and poultry manure is not treated in time, it will cause serious pollution to surface water, groundwater, soil and air. More seriously, for the convenience of transportation, small-scale farmers simply pile up the dung of beef cattle.

Put it next to the road without taking a scientific storage method. Due to neglect of management, wind and rain make feces flow everywhere. Such a situation is not conducive to the requirements of animal epidemic prevention, and will certainly have a certain impact on people's living environment.

-

Organic fertilizer production line equipment, the process layout is compact, scientific and reasonable, no three emissions, stable operation, reliable operation, convenient maintenance, and wide adaptability of raw materials. Organic compound fertilizers, bio-organic fertilizers, urban sludge, and domestic waste organic fertilizers that adapt to various ratios are the promotion projects of national environmental protection practical technologies. Cow dung is rich in organic matter, which can provide nutrients for crop growth and fertilize. Improve soil. There are many kinds of organic fertilizers, the raw materials are very wide, and the fertilizers are also ever-changing.

-

The organic fertilizer production process is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete set of equipment for the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system, cooling and drying system, It consists of a screening system and a finished product packaging system. The equipment requirements of each link system of the organic fertilizer production process are described in detail below: the fermentation system of the organic fertilizer production process consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary liter

It is composed of a drop-type turning and polishing machine and an electrical automatic control system; the main equipment of the drying system is a belt conveyor, a rotary drum dryer, a cooler, an induced draft fan, a hot blast furnace, etc.; the deodorization and dust removal system is composed of a sedimentation chamber, a dust removal chamber, etc. , Hengmu Machinery provides free drawings and guides users to build for free; the crushing system includes new semi-wet material crushers, chain crushers or cage crushers, belt conveyors, etc. The batching system includes electronic batching systems, Disc feeder, vibrating screen, can configure 6-8 at a time

raw materials, etc.;

The mixing system consists of optional horizontal mixers or disc mixers, vibrating screens, mobile belt conveyors, etc. The granulation system of the organic fertilizer production process needs to use granulator equipment, and the optional granulator equipment includes: : Compound fertilizer counter-rolling extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, organic fertilizer special granulator,

Rotary drum granulator, rounding machine, compound fertilizer special granulator, etc. The cooling and drying system can be used for rotary dryer, rotary drum cooler and other equipment for drying and cooling. The screening system is mainly completed by a trommel screening machine, and a primary screening machine and a secondary screening machine can be set up to make the finished product rate higher and the particles better; the finished product packaging system generally includes electronic quantitative packaging scales, silos, automatic sewing machines, etc. . In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized.

-

For more product details: please call 15993745555

Technical parameters

-

- Commodity name: Cow Dung Organic Fertilizer

- Production capacity: Annual output of 10,000-200,000 tons of cow dung organic fertilizer

- Applicable materials: Cow dung, etc.

- Applications: Production of cow dung organic fertilizer, etc.

The cow dung organic fertilizer production line is a complete set of equipment for processing organic fertilizer from cow dung. The cow dung processing machine can be used to pump the cow dung in the manure pond to the equipment through the mud pump, and then it can be dehydrated by the equipment. % or so, crops such as straw and rice bran (including N\P\K) can also be used as fillers, and then sprinkle with biological inoculum, and 1KG of inoculum is mixed with 20KG of water and moved into the raw materials, which can ferment 1 ton of raw materials. Turn and toss once every 1-2 days, generally 7-10 days can be completely decomposed. Small investment, quick return on capital, closer

The pollution of livestock and poultry manure and the residues of livestock and poultry products poses a problem to human health. Pollution from livestock and poultry farming has become a major source of pollution in rural China. The huge data of livestock and poultry production cannot but be paid attention to, if not handled properly, it will cause serious pollution to the environment. For example, because livestock and poultry manure is not treated in time, it will cause serious pollution to surface water, groundwater, soil and air. More seriously, for the convenience of transportation, small-scale farmers simply pile up the dung of beef cattle.

Put it next to the road without taking a scientific storage method. Due to neglect of management, wind and rain make feces flow everywhere. Such a situation is not conducive to the requirements of animal epidemic prevention, and will certainly have a certain impact on people's living environment.

-

Organic fertilizer production line equipment, the process layout is compact, scientific and reasonable, no three emissions, stable operation, reliable operation, convenient maintenance, and wide adaptability of raw materials. Organic compound fertilizers, bio-organic fertilizers, urban sludge, and domestic waste organic fertilizers that adapt to various ratios are the promotion projects of national environmental protection practical technologies. Cow dung is rich in organic matter, which can provide nutrients for crop growth and fertilize. Improve soil. There are many kinds of organic fertilizers, the raw materials are very wide, and the fertilizers are also ever-changing.

-

The organic fertilizer production process is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete set of equipment for the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system, cooling and drying system, It consists of a screening system and a finished product packaging system. The equipment requirements of each link system of the organic fertilizer production process are described in detail below: the fermentation system of the organic fertilizer production process consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary liter

It is composed of a drop-type turning and polishing machine and an electrical automatic control system; the main equipment of the drying system is a belt conveyor, a rotary drum dryer, a cooler, an induced draft fan, a hot blast furnace, etc.; the deodorization and dust removal system is composed of a sedimentation chamber, a dust removal chamber, etc. , Hengmu Machinery provides free drawings and guides users to build for free; the crushing system includes new semi-wet material crushers, chain crushers or cage crushers, belt conveyors, etc. The batching system includes electronic batching systems, Disc feeder, vibrating screen, can configure 6-8 at a time

raw materials, etc.;

The mixing system consists of optional horizontal mixers or disc mixers, vibrating screens, mobile belt conveyors, etc. The granulation system of the organic fertilizer production process needs to use granulator equipment, and the optional granulator equipment includes: : Compound fertilizer counter-rolling extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, organic fertilizer special granulator,

Rotary drum granulator, rounding machine, compound fertilizer special granulator, etc. The cooling and drying system can be used for rotary dryer, rotary drum cooler and other equipment for drying and cooling. The screening system is mainly completed by a trommel screening machine, and a primary screening machine and a secondary screening machine can be set up to make the finished product rate higher and the particles better; the finished product packaging system generally includes electronic quantitative packaging scales, silos, automatic sewing machines, etc. . In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized.

-

For more product details: please call 15993745555

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry