Chicken manure organic fertilizer and detailed text

- Production capacity: Annual output of 10,000-200,000 tons of chicken manure organic fertilizer

- Applicable materials: Chicken manure

- Applications: Production of chicken manure organic fertilizer

Classification:

Tel:

Introduction

-

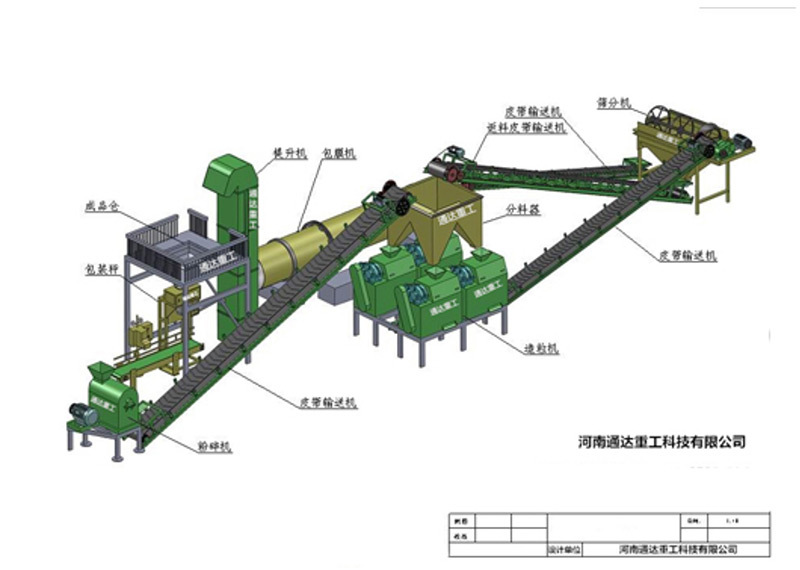

Chicken manure is a relatively high-quality organic fertilizer, and its content of pure nitrogen, phosphorus (P205) and potassium (K20) is about 1.63%, 1.54%, and 0.085%. Chicken manure must be decomposed by a decomposer before application, and the parasites and their eggs in the chicken manure, as well as some infectious bacteria, are inactivated and deodorized through the process after decomposing. The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. Chicken manure organic fertilizer production process

It roughly includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the entire raw materials should be matched as follows: 100-60 mesh raw materials account for about 30% to 40%, 60 mesh to 1.00mm diameter raw materials account for about 35%, and 1.00-2.00mm diameter small particles about It accounts for 25% to 30%. The higher the fineness of the material, the better the viscosity, and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the whole raw material

It should be matched as follows: 100-60 mesh raw materials account for about 30%-40%, 60-mesh to diameter 1.00mm raw materials account for about 35%, and small particles with a diameter of 1.00-2.00mm account for about 25%-30%, the finer the material. The higher the viscosity, the better the viscosity and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. The equipment requirements for each link system of the organic fertilizer production process are described in detail below: the fermentation system consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary lift-type turning machine and an electrical automatic control system; the main components of the drying system are The equipment includes belt conveyor, rotary dryer, cooler, induced draft fan, hot blast stove, etc. The deodorization and dust removal system consists of settling chamber, dust removal chamber, etc. Hengmu Machinery provides free drawings and guides users to build for free; Including Hengmu Machinery's new semi-wet material pulverizer, chain pulverizer or cage pulverizer, belt

Conveyors, etc.; the batching system includes electronic batching system, disc feeder, vibrating screen, which can be configured with 6-8 kinds of raw materials at a time; the mixing system has optional horizontal mixer or disc mixer, vibrating screen, Mobile belt conveyor, etc.;The granulation system needs to use granulator equipment. The optional granulator equipment includes: compound fertilizer double-roll extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, Special granulator for organic fertilizer, drum granulator, rounding machine, special granulator for compound fertilizer, etc. The screening system is mainly completed by a drum screening machine. High rate, good particles; finished product packaging system is general

Including electronic quantitative packaging scales, silos, automatic sewing machines, etc. In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized. The construction scale of the equipment configuration of the chicken manure organic fertilizer production line is generally 30,000 to 100,000 tons per year. It is necessary to comprehensively consider local resources, market capacity, and market coverage. The investment scale and product plan design need to be formulated according to the following conditions: characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, factory site conditions, production automation, etc.For more product details: please call 15993745555

Finished pellets

undefined

Features

-

- Commodity name: Chicken manure organic fertilizer and detailed text

- Production capacity: Annual output of 10,000-200,000 tons of chicken manure organic fertilizer

- Applicable materials: Chicken manure

- Applications: Production of chicken manure organic fertilizer

Chicken manure is a relatively high-quality organic fertilizer, and its content of pure nitrogen, phosphorus (P205) and potassium (K20) is about 1.63%, 1.54%, and 0.085%. Chicken manure must be decomposed by a decomposer before application, and the parasites and their eggs in the chicken manure, as well as some infectious bacteria, are inactivated and deodorized through the process after decomposing. The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. Chicken manure organic fertilizer production process

It roughly includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the entire raw materials should be matched as follows: 100-60 mesh raw materials account for about 30% to 40%, 60 mesh to 1.00mm diameter raw materials account for about 35%, and 1.00-2.00mm diameter small particles about It accounts for 25% to 30%. The higher the fineness of the material, the better the viscosity, and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the whole raw material

It should be matched as follows: 100-60 mesh raw materials account for about 30%-40%, 60-mesh to diameter 1.00mm raw materials account for about 35%, and small particles with a diameter of 1.00-2.00mm account for about 25%-30%, the finer the material. The higher the viscosity, the better the viscosity and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. The equipment requirements for each link system of the organic fertilizer production process are described in detail below: the fermentation system consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary lift-type turning machine and an electrical automatic control system; the main components of the drying system are The equipment includes belt conveyor, rotary dryer, cooler, induced draft fan, hot blast stove, etc. The deodorization and dust removal system consists of settling chamber, dust removal chamber, etc. Hengmu Machinery provides free drawings and guides users to build for free; Including Hengmu Machinery's new semi-wet material pulverizer, chain pulverizer or cage pulverizer, belt

Conveyors, etc.; the batching system includes electronic batching system, disc feeder, vibrating screen, which can be configured with 6-8 kinds of raw materials at a time; the mixing system has optional horizontal mixer or disc mixer, vibrating screen, Mobile belt conveyor, etc.;The granulation system needs to use granulator equipment. The optional granulator equipment includes: compound fertilizer double-roll extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, Special granulator for organic fertilizer, drum granulator, rounding machine, special granulator for compound fertilizer, etc. The screening system is mainly completed by a drum screening machine. High rate, good particles; finished product packaging system is general

Including electronic quantitative packaging scales, silos, automatic sewing machines, etc. In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized. The construction scale of the equipment configuration of the chicken manure organic fertilizer production line is generally 30,000 to 100,000 tons per year. It is necessary to comprehensively consider local resources, market capacity, and market coverage. The investment scale and product plan design need to be formulated according to the following conditions: characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, factory site conditions, production automation, etc.For more product details: please call 15993745555

Working Principle

-

- Commodity name: Chicken manure organic fertilizer and detailed text

- Production capacity: Annual output of 10,000-200,000 tons of chicken manure organic fertilizer

- Applicable materials: Chicken manure

- Applications: Production of chicken manure organic fertilizer

Chicken manure is a relatively high-quality organic fertilizer, and its content of pure nitrogen, phosphorus (P205) and potassium (K20) is about 1.63%, 1.54%, and 0.085%. Chicken manure must be decomposed by a decomposer before application, and the parasites and their eggs in the chicken manure, as well as some infectious bacteria, are inactivated and deodorized through the process after decomposing. The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. Chicken manure organic fertilizer production process

It roughly includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the entire raw materials should be matched as follows: 100-60 mesh raw materials account for about 30% to 40%, 60 mesh to 1.00mm diameter raw materials account for about 35%, and 1.00-2.00mm diameter small particles about It accounts for 25% to 30%. The higher the fineness of the material, the better the viscosity, and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the whole raw material

It should be matched as follows: 100-60 mesh raw materials account for about 30%-40%, 60-mesh to diameter 1.00mm raw materials account for about 35%, and small particles with a diameter of 1.00-2.00mm account for about 25%-30%, the finer the material. The higher the viscosity, the better the viscosity and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. The equipment requirements for each link system of the organic fertilizer production process are described in detail below: the fermentation system consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary lift-type turning machine and an electrical automatic control system; the main components of the drying system are The equipment includes belt conveyor, rotary dryer, cooler, induced draft fan, hot blast stove, etc. The deodorization and dust removal system consists of settling chamber, dust removal chamber, etc. Hengmu Machinery provides free drawings and guides users to build for free; Including Hengmu Machinery's new semi-wet material pulverizer, chain pulverizer or cage pulverizer, belt

Conveyors, etc.; the batching system includes electronic batching system, disc feeder, vibrating screen, which can be configured with 6-8 kinds of raw materials at a time; the mixing system has optional horizontal mixer or disc mixer, vibrating screen, Mobile belt conveyor, etc.;The granulation system needs to use granulator equipment. The optional granulator equipment includes: compound fertilizer double-roll extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, Special granulator for organic fertilizer, drum granulator, rounding machine, special granulator for compound fertilizer, etc. The screening system is mainly completed by a drum screening machine. High rate, good particles; finished product packaging system is general

Including electronic quantitative packaging scales, silos, automatic sewing machines, etc. In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized. The construction scale of the equipment configuration of the chicken manure organic fertilizer production line is generally 30,000 to 100,000 tons per year. It is necessary to comprehensively consider local resources, market capacity, and market coverage. The investment scale and product plan design need to be formulated according to the following conditions: characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, factory site conditions, production automation, etc.For more product details: please call 15993745555

Technical parameters

-

- Commodity name: Chicken manure organic fertilizer and detailed text

- Production capacity: Annual output of 10,000-200,000 tons of chicken manure organic fertilizer

- Applicable materials: Chicken manure

- Applications: Production of chicken manure organic fertilizer

Chicken manure is a relatively high-quality organic fertilizer, and its content of pure nitrogen, phosphorus (P205) and potassium (K20) is about 1.63%, 1.54%, and 0.085%. Chicken manure must be decomposed by a decomposer before application, and the parasites and their eggs in the chicken manure, as well as some infectious bacteria, are inactivated and deodorized through the process after decomposing. The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. Chicken manure organic fertilizer production process

It roughly includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the entire raw materials should be matched as follows: 100-60 mesh raw materials account for about 30% to 40%, 60 mesh to 1.00mm diameter raw materials account for about 35%, and 1.00-2.00mm diameter small particles about It accounts for 25% to 30%. The higher the fineness of the material, the better the viscosity, and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken organic fertilizer generally includes: raw material selection (chicken manure, etc.) → drying and sterilization → ingredient mixing → granulation → cooling and screening → metering and sealing → finished product storage.

The complex production process of chicken manure organic fertilizer is as follows: organic fertilizer raw materials (animal manure, domestic waste, dead branches, rotten leaves, biogas residue, waste bacteria, etc.) are fermented and entered into a semi-wet material pulverizer for pulverization, and then nitrogen is added. Phosphorus and potassium and other elements (pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) make the contained mineral elements meet the required standards, and then a mixer is used to stir them, and then enter the granulation mechanism to granulate, and dry them after they come out. The products are screened by the screening machine, the qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable matching of the fineness of raw materials is very important for the production process of organic fertilizer. According to the experience of Tongda Heavy Industry, the fineness of the whole raw material

It should be matched as follows: 100-60 mesh raw materials account for about 30%-40%, 60-mesh to diameter 1.00mm raw materials account for about 35%, and small particles with a diameter of 1.00-2.00mm account for about 25%-30%, the finer the material. The higher the viscosity, the better the viscosity and the higher the surface finish of the granulated particles. However, in the production process, the use of an excessive proportion of high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity. -

The production process of chicken manure organic fertilizer is closely related to the equipment configuration of the organic fertilizer production line. Generally, the complete equipment of the organic fertilizer production line is mainly composed of fermentation system, drying system, deodorization and dust removal system, crushing system, batching system, mixing system, granulation system and screening system. and finished product packaging system. The equipment requirements for each link system of the organic fertilizer production process are described in detail below: the fermentation system consists of a feed conveyor, a biological deodorizer, a mixing mixer, a proprietary lift-type turning machine and an electrical automatic control system; the main components of the drying system are The equipment includes belt conveyor, rotary dryer, cooler, induced draft fan, hot blast stove, etc. The deodorization and dust removal system consists of settling chamber, dust removal chamber, etc. Hengmu Machinery provides free drawings and guides users to build for free; Including Hengmu Machinery's new semi-wet material pulverizer, chain pulverizer or cage pulverizer, belt

Conveyors, etc.; the batching system includes electronic batching system, disc feeder, vibrating screen, which can be configured with 6-8 kinds of raw materials at a time; the mixing system has optional horizontal mixer or disc mixer, vibrating screen, Mobile belt conveyor, etc.;The granulation system needs to use granulator equipment. The optional granulator equipment includes: compound fertilizer double-roll extrusion granulator, disc granulator, flat film granulator, bio-organic fertilizer spherical granulator, Special granulator for organic fertilizer, drum granulator, rounding machine, special granulator for compound fertilizer, etc. The screening system is mainly completed by a drum screening machine. High rate, good particles; finished product packaging system is general

Including electronic quantitative packaging scales, silos, automatic sewing machines, etc. In this way, fully automatic and non-intermittent production of organic fertilizer production lines can be realized. The construction scale of the equipment configuration of the chicken manure organic fertilizer production line is generally 30,000 to 100,000 tons per year. It is necessary to comprehensively consider local resources, market capacity, and market coverage. The investment scale and product plan design need to be formulated according to the following conditions: characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, factory site conditions, production automation, etc.For more product details: please call 15993745555

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry