Cyclone

- Production capacity: 1-6t/h

- Applicable materials: Livestock manure

- Applications: Farms

Classification:

Tel:

Introduction

-

Cyclone dust collector is a type of dust removal device. The dust removal mechanism is to make the dust-laden air flow rotate, separate the dust particles from the air flow with the help of centrifugal force and trap them in the device, and then make the dust particles fall into the ash hopper with the help of gravity. Each component of the cyclone dust collector has a certain size ratio. The interaction of each proportional relationship can affect the efficiency and pressure loss of the cyclone dust collector. Among them, the diameter of the dust collector, the size of the air inlet, and the diameter of the exhaust pipe are the main influences. factor. Interest should be noted when using, when a certain limit is exceeded, favorable factors can also be transformed into unfavorable factors. In addition, some factors are beneficial to improve the dust removal efficiency, but will increase the pressure loss, so the adjustment of each factor must be taken into account.

-

The cyclone dust collector is composed of an intake pipe, an exhaust battalion, a circular cylinder, a cone and an ash hopper. The cyclone dust collector has a simple structure, is easy to manufacture, install and maintain, and has low equipment investment and operating costs. It has been widely used to separate solid and liquid particles from airflow, or to separate solid particles from liquid. Under ordinary operating conditions, the centrifugal force acting on the particles is 5 to 2500 times that of gravity, so the efficiency of the cyclone dust collector is significantly higher than that of the gravity settling chamber. Using this principle, a dust removal efficiency of 100% was successfully developed. More than 90 cyclone dust removal devices. Among the mechanical dust collectors, the cyclone dust collector is a relatively efficient one. It is suitable for the removal of non-viscous and non-fibrous dust. Most of them are used to remove particles above 5 μm. The parallel multi-tube cyclone dust collector device It also has a dust removal efficiency of 80 to 85% for particles of 3 μm. The cyclone dust collector constructed of special metal or ceramic materials with high temperature resistance, abrasion resistance and corrosion resistance can be operated under the conditions of temperature up to 1000℃ and pressure up to 500×105Pa. Considering the technical and economic aspects, the pressure loss control range of the cyclone dust collector is generally 500-2000Pa. Therefore, it is a medium-efficiency dust collector and can be used for the purification of high-temperature flue gas. Its main disadvantage is the low removal efficiency of fine dust particles (<5μm).

-

Finished pellets

undefined

Features

-

- Commodity name: Cyclone

- Production capacity: 1-6t/h

- Applicable materials: Livestock manure

- Applications: Farms

Cyclone dust collector is a type of dust removal device. The dust removal mechanism is to make the dust-laden air flow rotate, separate the dust particles from the air flow with the help of centrifugal force and trap them in the device, and then make the dust particles fall into the ash hopper with the help of gravity. Each component of the cyclone dust collector has a certain size ratio. The interaction of each proportional relationship can affect the efficiency and pressure loss of the cyclone dust collector. Among them, the diameter of the dust collector, the size of the air inlet, and the diameter of the exhaust pipe are the main influences. factor. Interest should be noted when using, when a certain limit is exceeded, favorable factors can also be transformed into unfavorable factors. In addition, some factors are beneficial to improve the dust removal efficiency, but will increase the pressure loss, so the adjustment of each factor must be taken into account.

-

The cyclone dust collector is composed of an intake pipe, an exhaust battalion, a circular cylinder, a cone and an ash hopper. The cyclone dust collector has a simple structure, is easy to manufacture, install and maintain, and has low equipment investment and operating costs. It has been widely used to separate solid and liquid particles from airflow, or to separate solid particles from liquid. Under ordinary operating conditions, the centrifugal force acting on the particles is 5 to 2500 times that of gravity, so the efficiency of the cyclone dust collector is significantly higher than that of the gravity settling chamber. Using this principle, a dust removal efficiency of 100% was successfully developed. More than 90 cyclone dust removal devices. Among the mechanical dust collectors, the cyclone dust collector is a relatively efficient one. It is suitable for the removal of non-viscous and non-fibrous dust. Most of them are used to remove particles above 5 μm. The parallel multi-tube cyclone dust collector device It also has a dust removal efficiency of 80 to 85% for particles of 3 μm. The cyclone dust collector constructed of special metal or ceramic materials with high temperature resistance, abrasion resistance and corrosion resistance can be operated under the conditions of temperature up to 1000℃ and pressure up to 500×105Pa. Considering the technical and economic aspects, the pressure loss control range of the cyclone dust collector is generally 500-2000Pa. Therefore, it is a medium-efficiency dust collector and can be used for the purification of high-temperature flue gas. Its main disadvantage is the low removal efficiency of fine dust particles (<5μm).

-

Working Principle

-

- Commodity name: Cyclone

- Production capacity: 1-6t/h

- Applicable materials: Livestock manure

- Applications: Farms

Cyclone dust collector is a type of dust removal device. The dust removal mechanism is to make the dust-laden air flow rotate, separate the dust particles from the air flow with the help of centrifugal force and trap them in the device, and then make the dust particles fall into the ash hopper with the help of gravity. Each component of the cyclone dust collector has a certain size ratio. The interaction of each proportional relationship can affect the efficiency and pressure loss of the cyclone dust collector. Among them, the diameter of the dust collector, the size of the air inlet, and the diameter of the exhaust pipe are the main influences. factor. Interest should be noted when using, when a certain limit is exceeded, favorable factors can also be transformed into unfavorable factors. In addition, some factors are beneficial to improve the dust removal efficiency, but will increase the pressure loss, so the adjustment of each factor must be taken into account.

-

The cyclone dust collector is composed of an intake pipe, an exhaust battalion, a circular cylinder, a cone and an ash hopper. The cyclone dust collector has a simple structure, is easy to manufacture, install and maintain, and has low equipment investment and operating costs. It has been widely used to separate solid and liquid particles from airflow, or to separate solid particles from liquid. Under ordinary operating conditions, the centrifugal force acting on the particles is 5 to 2500 times that of gravity, so the efficiency of the cyclone dust collector is significantly higher than that of the gravity settling chamber. Using this principle, a dust removal efficiency of 100% was successfully developed. More than 90 cyclone dust removal devices. Among the mechanical dust collectors, the cyclone dust collector is a relatively efficient one. It is suitable for the removal of non-viscous and non-fibrous dust. Most of them are used to remove particles above 5 μm. The parallel multi-tube cyclone dust collector device It also has a dust removal efficiency of 80 to 85% for particles of 3 μm. The cyclone dust collector constructed of special metal or ceramic materials with high temperature resistance, abrasion resistance and corrosion resistance can be operated under the conditions of temperature up to 1000℃ and pressure up to 500×105Pa. Considering the technical and economic aspects, the pressure loss control range of the cyclone dust collector is generally 500-2000Pa. Therefore, it is a medium-efficiency dust collector and can be used for the purification of high-temperature flue gas. Its main disadvantage is the low removal efficiency of fine dust particles (<5μm).

-

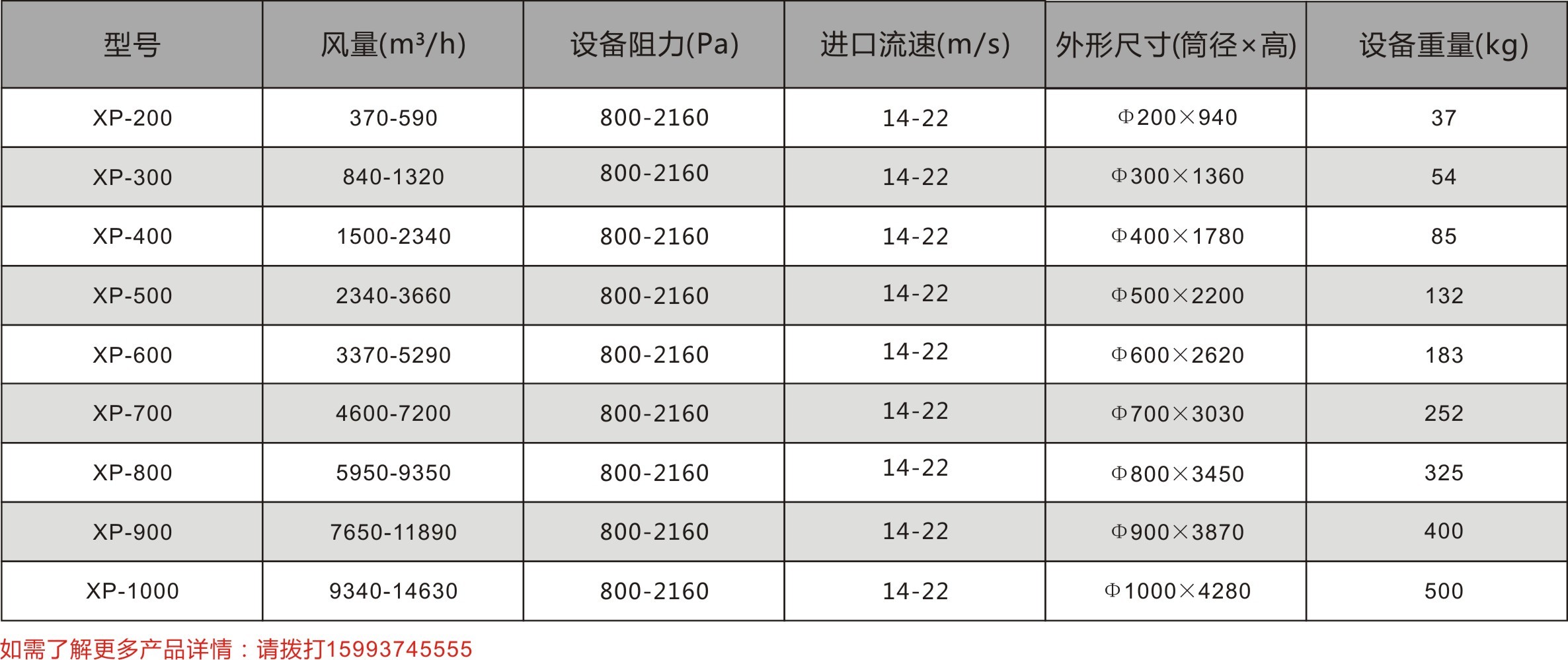

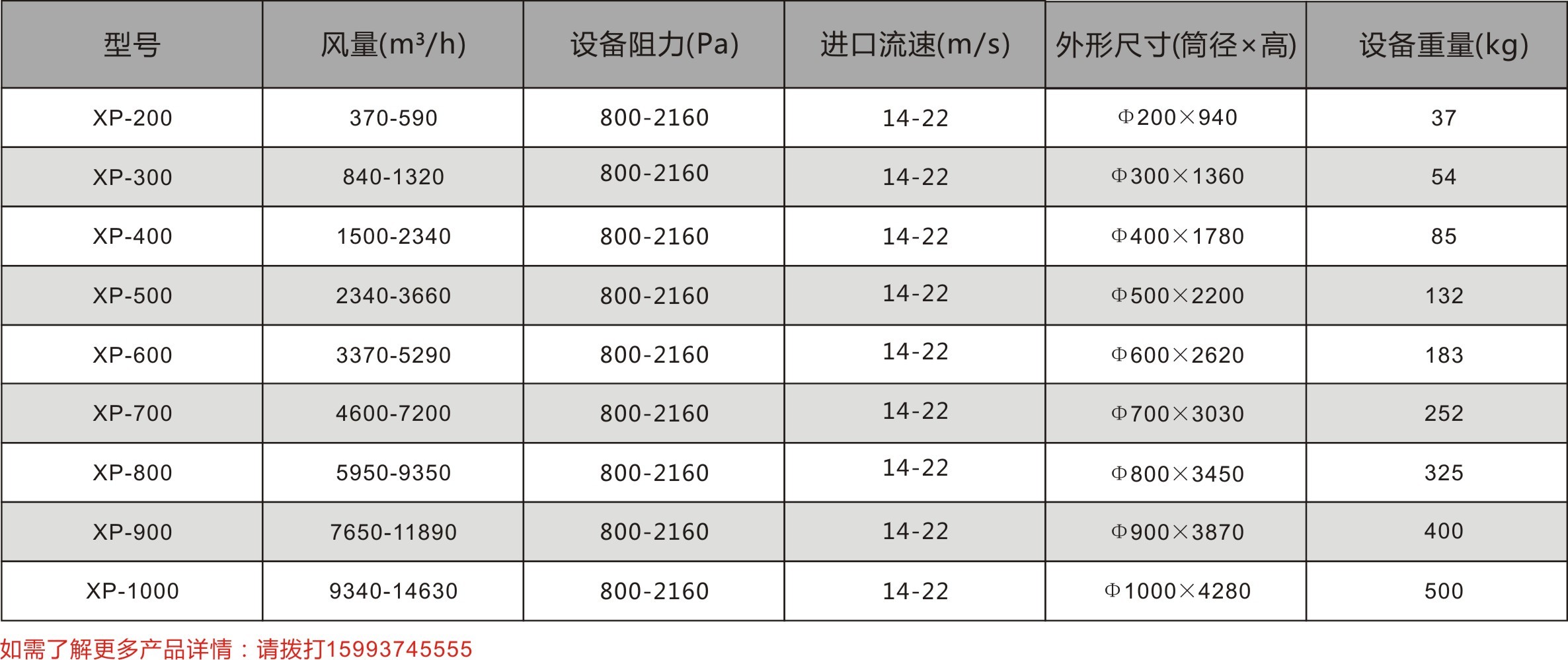

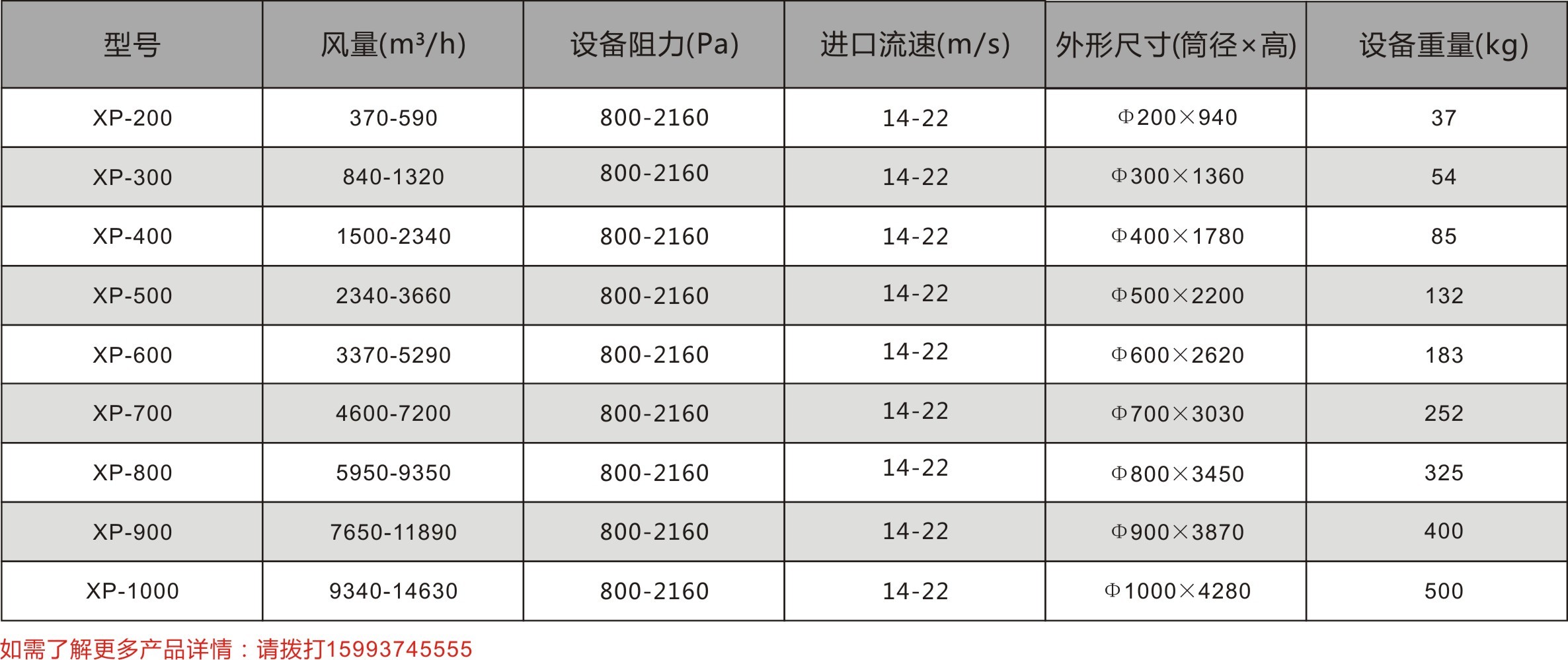

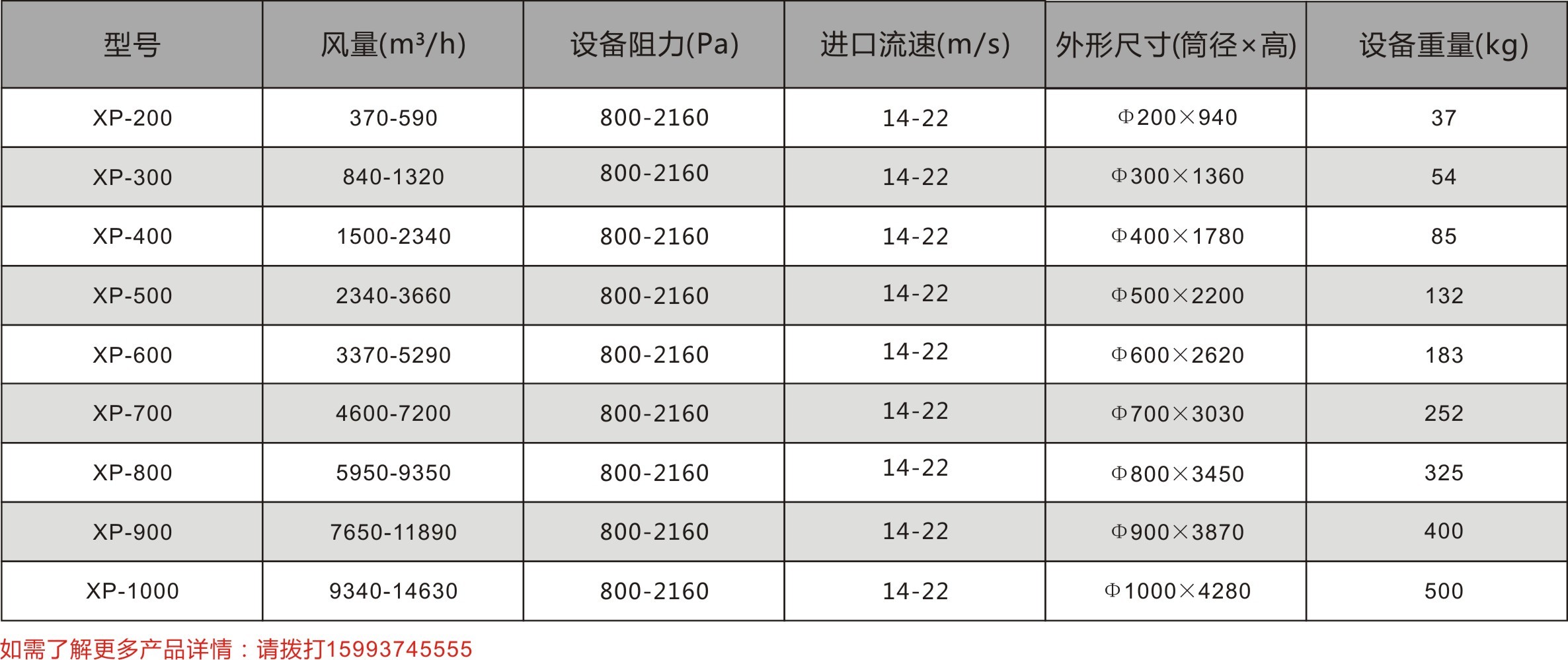

Technical parameters

-

- Commodity name: Cyclone

- Production capacity: 1-6t/h

- Applicable materials: Livestock manure

- Applications: Farms

Cyclone dust collector is a type of dust removal device. The dust removal mechanism is to make the dust-laden air flow rotate, separate the dust particles from the air flow with the help of centrifugal force and trap them in the device, and then make the dust particles fall into the ash hopper with the help of gravity. Each component of the cyclone dust collector has a certain size ratio. The interaction of each proportional relationship can affect the efficiency and pressure loss of the cyclone dust collector. Among them, the diameter of the dust collector, the size of the air inlet, and the diameter of the exhaust pipe are the main influences. factor. Interest should be noted when using, when a certain limit is exceeded, favorable factors can also be transformed into unfavorable factors. In addition, some factors are beneficial to improve the dust removal efficiency, but will increase the pressure loss, so the adjustment of each factor must be taken into account.

-

The cyclone dust collector is composed of an intake pipe, an exhaust battalion, a circular cylinder, a cone and an ash hopper. The cyclone dust collector has a simple structure, is easy to manufacture, install and maintain, and has low equipment investment and operating costs. It has been widely used to separate solid and liquid particles from airflow, or to separate solid particles from liquid. Under ordinary operating conditions, the centrifugal force acting on the particles is 5 to 2500 times that of gravity, so the efficiency of the cyclone dust collector is significantly higher than that of the gravity settling chamber. Using this principle, a dust removal efficiency of 100% was successfully developed. More than 90 cyclone dust removal devices. Among the mechanical dust collectors, the cyclone dust collector is a relatively efficient one. It is suitable for the removal of non-viscous and non-fibrous dust. Most of them are used to remove particles above 5 μm. The parallel multi-tube cyclone dust collector device It also has a dust removal efficiency of 80 to 85% for particles of 3 μm. The cyclone dust collector constructed of special metal or ceramic materials with high temperature resistance, abrasion resistance and corrosion resistance can be operated under the conditions of temperature up to 1000℃ and pressure up to 500×105Pa. Considering the technical and economic aspects, the pressure loss control range of the cyclone dust collector is generally 500-2000Pa. Therefore, it is a medium-efficiency dust collector and can be used for the purification of high-temperature flue gas. Its main disadvantage is the low removal efficiency of fine dust particles (<5μm).

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry