Trommel screening machine

- Production capacity: 10-20 tons per hour

- Applicable materials: Minerals and biological raw materials

- Applications: Various industries

Classification:

Tel:

Introduction

-

The trommel screening machine is a new generation of new self-cleaning special equipment for screening materials after the electric vibrating box and the common mesh trommel screen produced by major domestic companies. It is widely used in the screening of various solid materials with a particle size less than 300mm. It has the characteristics of high screening efficiency, low noise, small dust volume, long service life, small maintenance amount, and convenient maintenance. Its screening capacity is 60 tons/hour to 1000 tons/hour. The comprehensive utilization power stations (mainly circulating brightening bed boilers) that mainly burn low-quality coal are rapidly emerging in China. The fuels mainly composed of coal ore and coal slime are usually sticky, wet and dirty, and miscellaneous. The coal conveying system generally exists. The screening machine is blocked, the screening efficiency is low, the crusher has a large grinding cost and high energy consumption.

-

The self-cleaning cage trommel screening machine implements reasonable rotation of the central separation drum of the equipment through the gearbox type deceleration system.

The screen is composed of circular flat steel rings. The center separation is simple and the installation is inclined to the ground plane. During the work, the material enters the screen from the upper end of the central separation drum. During the rotation of the separation drum, the fine materials pass through the ring from top to bottom. The coarse material is discharged from the lower end of the separator into the pulverizer. There is a plate-type automatic screen cleaning mechanism in the equipment. During the separation process, through the relative movement of the screen cleaning mechanism and the screen body, the screen body is continuously "combed" by the screen cleaning mechanism, so that the screen body is always kept clean during the whole working process. , the screening efficiency will not be affected by the filling of the screen holes. -

Finished pellets

undefined

Features

-

- Commodity name: Trommel screening machine

- Production capacity: 10-20 tons per hour

- Applicable materials: Minerals and biological raw materials

- Applications: Various industries

The trommel screening machine is a new generation of new self-cleaning special equipment for screening materials after the electric vibrating box and the common mesh trommel screen produced by major domestic companies. It is widely used in the screening of various solid materials with a particle size less than 300mm. It has the characteristics of high screening efficiency, low noise, small dust volume, long service life, small maintenance amount, and convenient maintenance. Its screening capacity is 60 tons/hour to 1000 tons/hour. The comprehensive utilization power stations (mainly circulating brightening bed boilers) that mainly burn low-quality coal are rapidly emerging in China. The fuels mainly composed of coal ore and coal slime are usually sticky, wet and dirty, and miscellaneous. The coal conveying system generally exists. The screening machine is blocked, the screening efficiency is low, the crusher has a large grinding cost and high energy consumption.

-

The self-cleaning cage trommel screening machine implements reasonable rotation of the central separation drum of the equipment through the gearbox type deceleration system.

The screen is composed of circular flat steel rings. The center separation is simple and the installation is inclined to the ground plane. During the work, the material enters the screen from the upper end of the central separation drum. During the rotation of the separation drum, the fine materials pass through the ring from top to bottom. The coarse material is discharged from the lower end of the separator into the pulverizer. There is a plate-type automatic screen cleaning mechanism in the equipment. During the separation process, through the relative movement of the screen cleaning mechanism and the screen body, the screen body is continuously "combed" by the screen cleaning mechanism, so that the screen body is always kept clean during the whole working process. , the screening efficiency will not be affected by the filling of the screen holes. -

Working Principle

-

- Commodity name: Trommel screening machine

- Production capacity: 10-20 tons per hour

- Applicable materials: Minerals and biological raw materials

- Applications: Various industries

The trommel screening machine is a new generation of new self-cleaning special equipment for screening materials after the electric vibrating box and the common mesh trommel screen produced by major domestic companies. It is widely used in the screening of various solid materials with a particle size less than 300mm. It has the characteristics of high screening efficiency, low noise, small dust volume, long service life, small maintenance amount, and convenient maintenance. Its screening capacity is 60 tons/hour to 1000 tons/hour. The comprehensive utilization power stations (mainly circulating brightening bed boilers) that mainly burn low-quality coal are rapidly emerging in China. The fuels mainly composed of coal ore and coal slime are usually sticky, wet and dirty, and miscellaneous. The coal conveying system generally exists. The screening machine is blocked, the screening efficiency is low, the crusher has a large grinding cost and high energy consumption.

-

The self-cleaning cage trommel screening machine implements reasonable rotation of the central separation drum of the equipment through the gearbox type deceleration system.

The screen is composed of circular flat steel rings. The center separation is simple and the installation is inclined to the ground plane. During the work, the material enters the screen from the upper end of the central separation drum. During the rotation of the separation drum, the fine materials pass through the ring from top to bottom. The coarse material is discharged from the lower end of the separator into the pulverizer. There is a plate-type automatic screen cleaning mechanism in the equipment. During the separation process, through the relative movement of the screen cleaning mechanism and the screen body, the screen body is continuously "combed" by the screen cleaning mechanism, so that the screen body is always kept clean during the whole working process. , the screening efficiency will not be affected by the filling of the screen holes. -

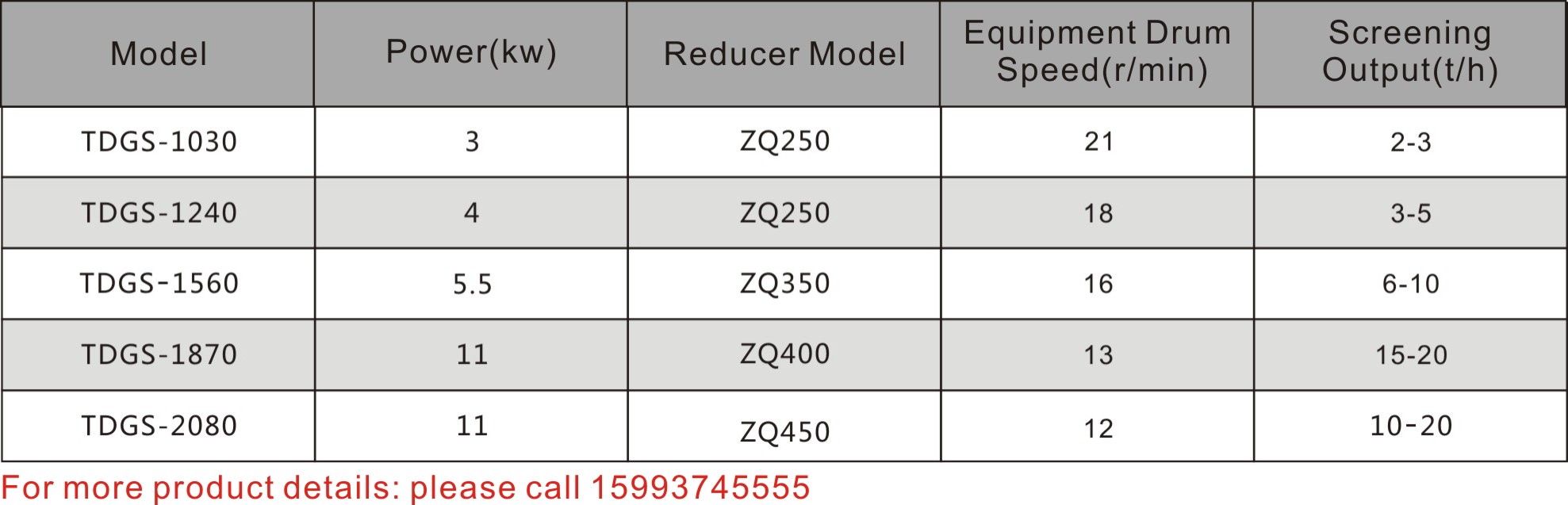

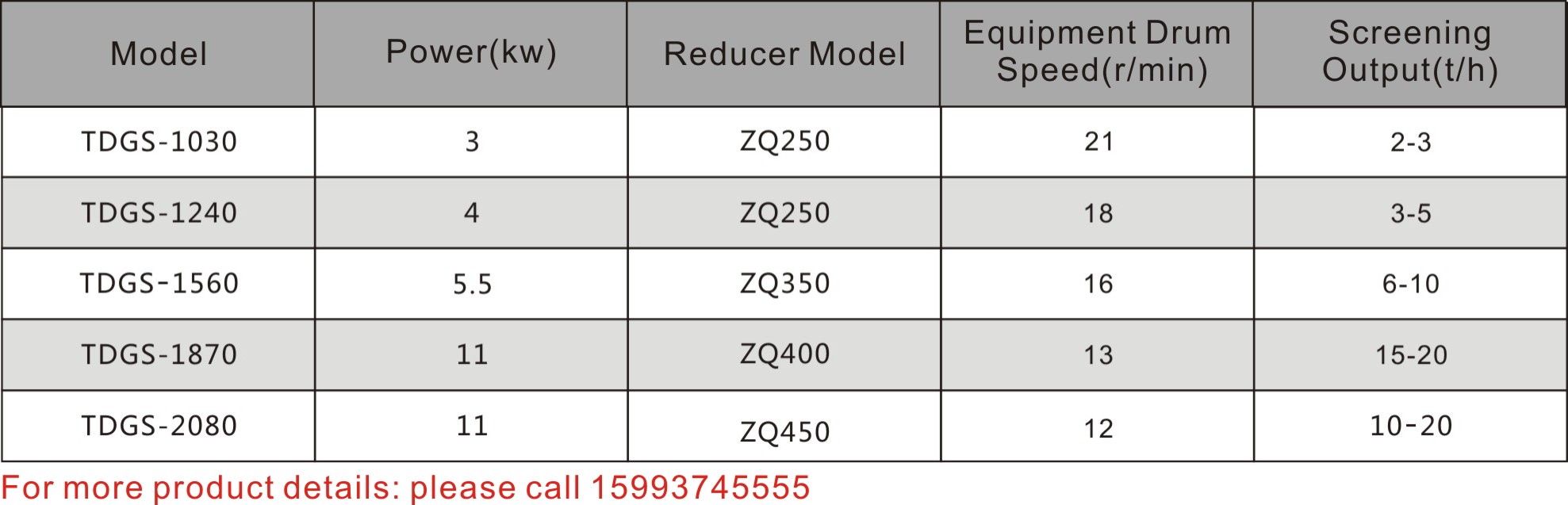

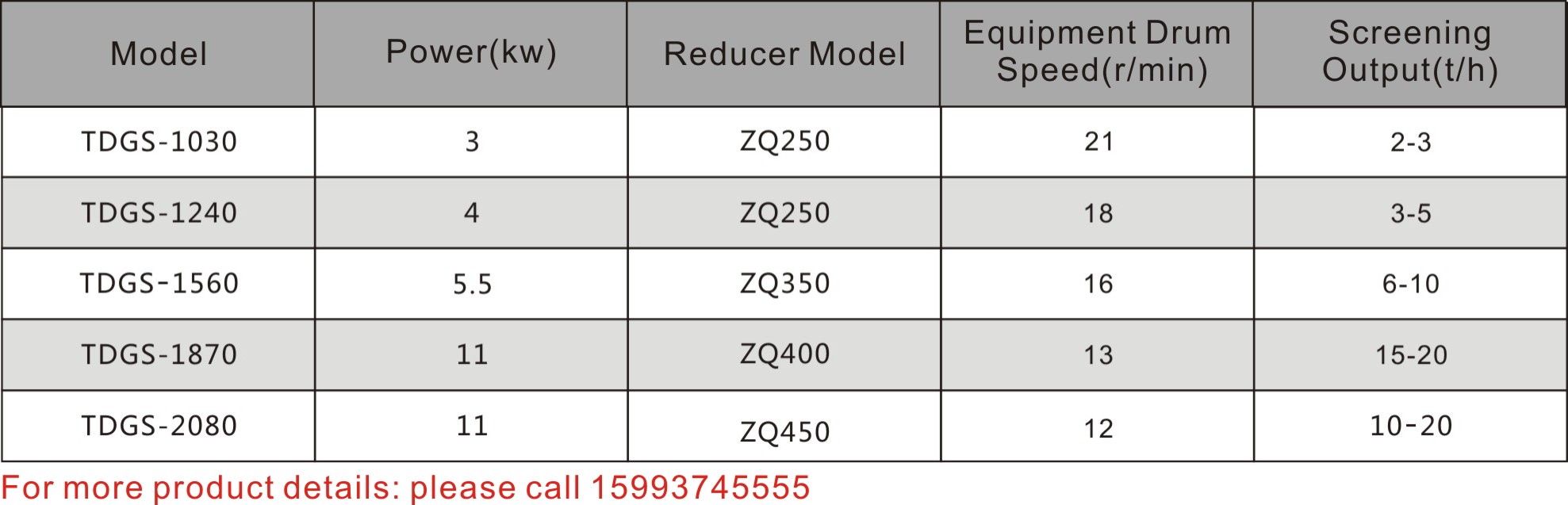

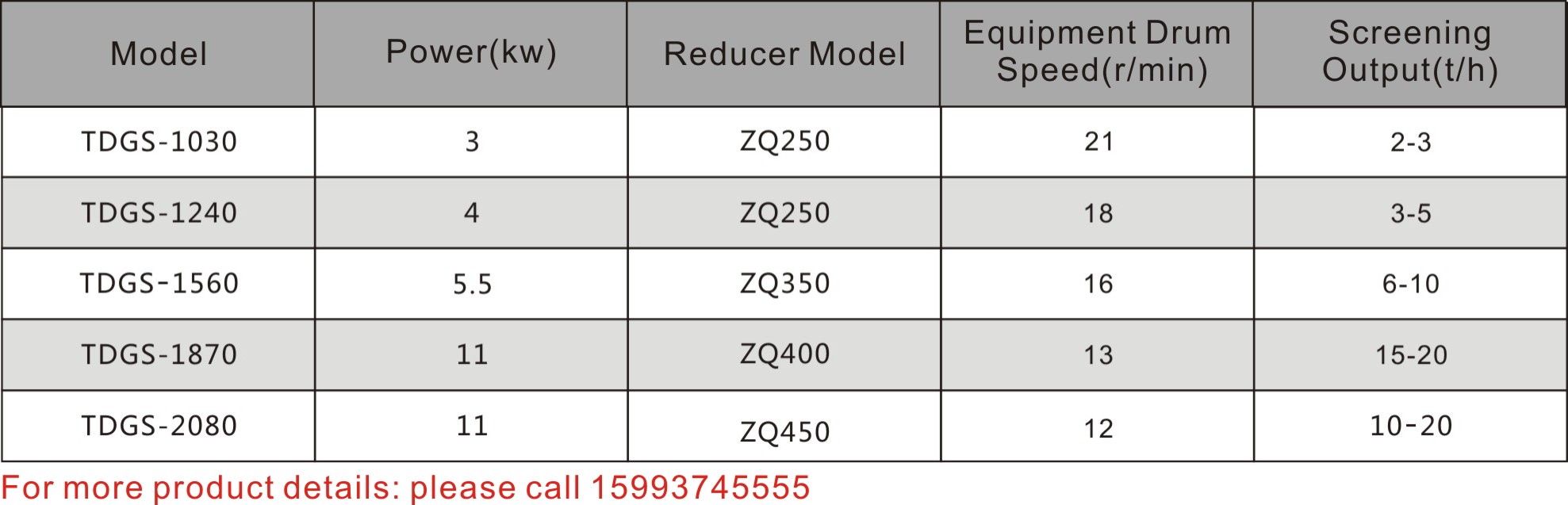

Technical parameters

-

- Commodity name: Trommel screening machine

- Production capacity: 10-20 tons per hour

- Applicable materials: Minerals and biological raw materials

- Applications: Various industries

The trommel screening machine is a new generation of new self-cleaning special equipment for screening materials after the electric vibrating box and the common mesh trommel screen produced by major domestic companies. It is widely used in the screening of various solid materials with a particle size less than 300mm. It has the characteristics of high screening efficiency, low noise, small dust volume, long service life, small maintenance amount, and convenient maintenance. Its screening capacity is 60 tons/hour to 1000 tons/hour. The comprehensive utilization power stations (mainly circulating brightening bed boilers) that mainly burn low-quality coal are rapidly emerging in China. The fuels mainly composed of coal ore and coal slime are usually sticky, wet and dirty, and miscellaneous. The coal conveying system generally exists. The screening machine is blocked, the screening efficiency is low, the crusher has a large grinding cost and high energy consumption.

-

The self-cleaning cage trommel screening machine implements reasonable rotation of the central separation drum of the equipment through the gearbox type deceleration system.

The screen is composed of circular flat steel rings. The center separation is simple and the installation is inclined to the ground plane. During the work, the material enters the screen from the upper end of the central separation drum. During the rotation of the separation drum, the fine materials pass through the ring from top to bottom. The coarse material is discharged from the lower end of the separator into the pulverizer. There is a plate-type automatic screen cleaning mechanism in the equipment. During the separation process, through the relative movement of the screen cleaning mechanism and the screen body, the screen body is continuously "combed" by the screen cleaning mechanism, so that the screen body is always kept clean during the whole working process. , the screening efficiency will not be affected by the filling of the screen holes. -

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry