Pan mixer

- Production capacity: 2-12t/h

- Applicable materials: A variety of materials

- Applications: Can be used in fertilizer processing, chemical metallurgy, mining, building materials and other industries

Classification:

Tel:

Introduction

-

The disc mixer is a new type of equipment improved on the basis of the original mixer. Mainly used in organic fertilizers, compound fertilizers and thermal power plants

Under the dust collector, it can also be used in chemical metallurgy, mining, building materials and other industries.

1.1 Purpose and advantages of the machine

1.1.1 Mainly used in organic fertilizers,

It can also be used in chemical metallurgy, mining, building materials and other industries under the dust collector of compound fertilizer and thermal power plant.

1.1.2 The advantages of a disc mixer are:

(1) It has high stirring efficiency and less floor space. The spiral blades are made of high wear-resistant special alloys.

(2) The disc mixer is driven by a reducer, with stable rotation and low noise.

(3) The disc mixer feeds from the top and discharges from the bottom, with a reasonable structure.

(4) The sealing between the joint surfaces is tight and the operation is stable.

-

The motor of the disc mixer drives the reducer to run, the reducer drives the main shaft, and the main shaft drives the stirring teeth to stir the materials.

-

Finished pellets

undefined

Features

-

- Commodity name: Pan mixer

- Production capacity: 2-12t/h

- Applicable materials: A variety of materials

- Applications: Can be used in fertilizer processing, chemical metallurgy, mining, building materials and other industries

The disc mixer is a new type of equipment improved on the basis of the original mixer. Mainly used in organic fertilizers, compound fertilizers and thermal power plants

Under the dust collector, it can also be used in chemical metallurgy, mining, building materials and other industries.

1.1 Purpose and advantages of the machine

1.1.1 Mainly used in organic fertilizers,

It can also be used in chemical metallurgy, mining, building materials and other industries under the dust collector of compound fertilizer and thermal power plant.

1.1.2 The advantages of a disc mixer are:

(1) It has high stirring efficiency and less floor space. The spiral blades are made of high wear-resistant special alloys.

(2) The disc mixer is driven by a reducer, with stable rotation and low noise.

(3) The disc mixer feeds from the top and discharges from the bottom, with a reasonable structure.

(4) The sealing between the joint surfaces is tight and the operation is stable.

-

The motor of the disc mixer drives the reducer to run, the reducer drives the main shaft, and the main shaft drives the stirring teeth to stir the materials.

-

Working Principle

-

- Commodity name: Pan mixer

- Production capacity: 2-12t/h

- Applicable materials: A variety of materials

- Applications: Can be used in fertilizer processing, chemical metallurgy, mining, building materials and other industries

The disc mixer is a new type of equipment improved on the basis of the original mixer. Mainly used in organic fertilizers, compound fertilizers and thermal power plants

Under the dust collector, it can also be used in chemical metallurgy, mining, building materials and other industries.

1.1 Purpose and advantages of the machine

1.1.1 Mainly used in organic fertilizers,

It can also be used in chemical metallurgy, mining, building materials and other industries under the dust collector of compound fertilizer and thermal power plant.

1.1.2 The advantages of a disc mixer are:

(1) It has high stirring efficiency and less floor space. The spiral blades are made of high wear-resistant special alloys.

(2) The disc mixer is driven by a reducer, with stable rotation and low noise.

(3) The disc mixer feeds from the top and discharges from the bottom, with a reasonable structure.

(4) The sealing between the joint surfaces is tight and the operation is stable.

-

The motor of the disc mixer drives the reducer to run, the reducer drives the main shaft, and the main shaft drives the stirring teeth to stir the materials.

-

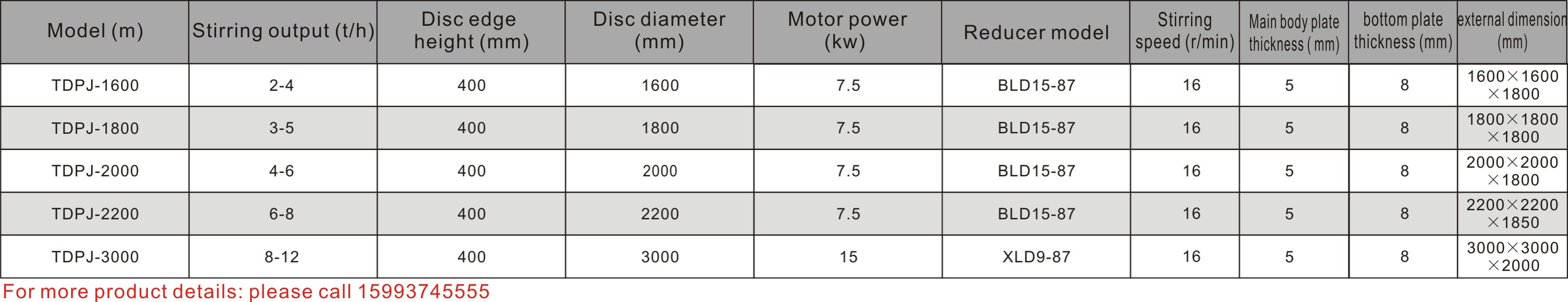

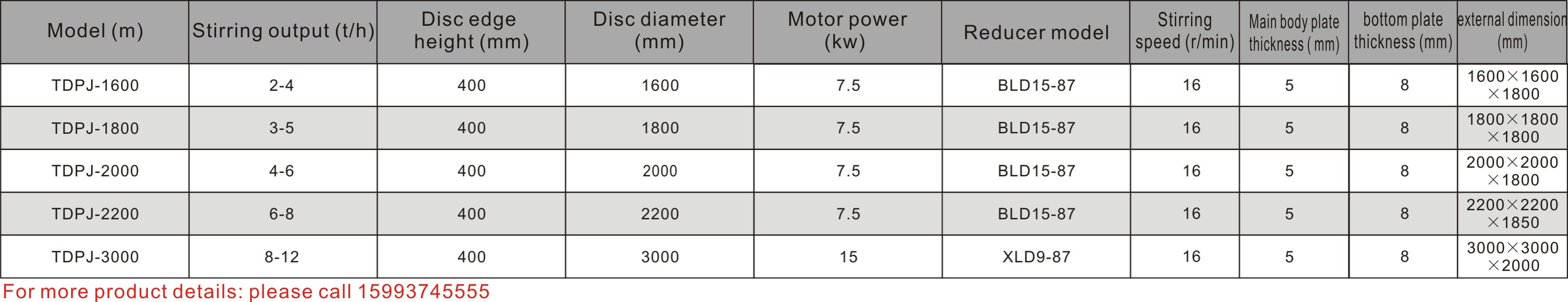

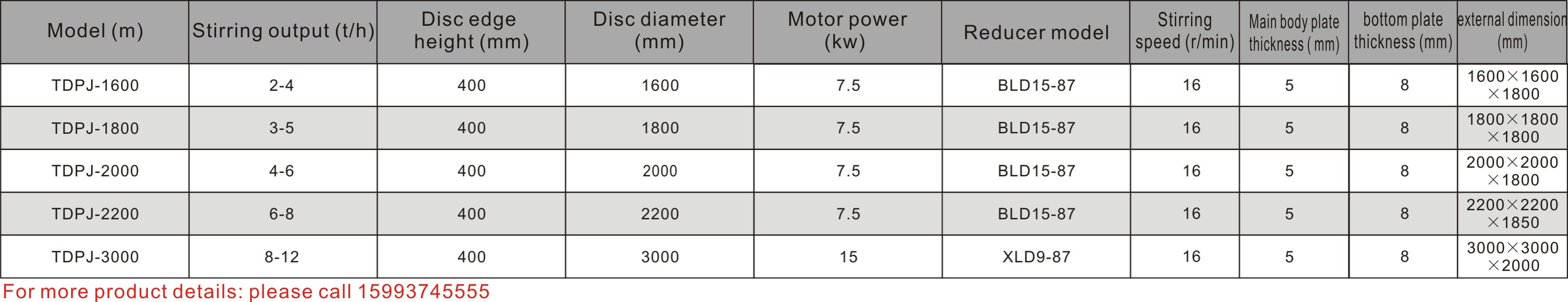

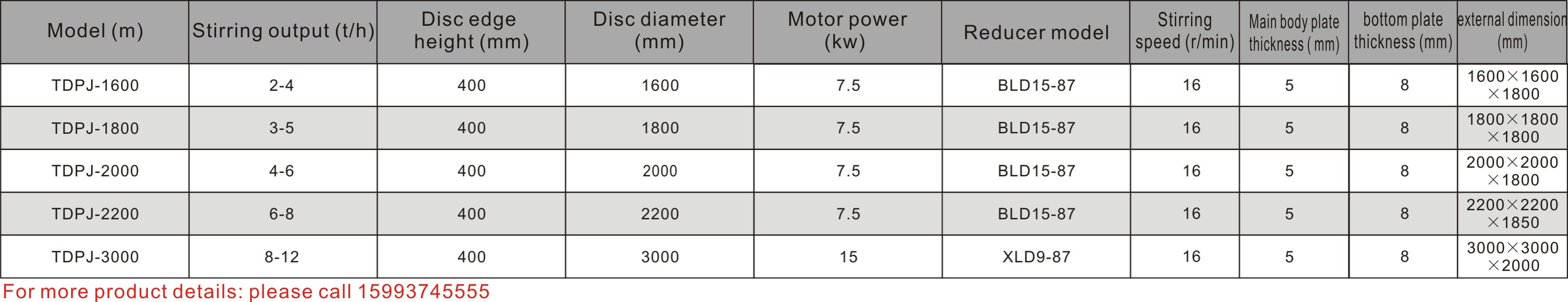

Technical parameters

-

- Commodity name: Pan mixer

- Production capacity: 2-12t/h

- Applicable materials: A variety of materials

- Applications: Can be used in fertilizer processing, chemical metallurgy, mining, building materials and other industries

The disc mixer is a new type of equipment improved on the basis of the original mixer. Mainly used in organic fertilizers, compound fertilizers and thermal power plants

Under the dust collector, it can also be used in chemical metallurgy, mining, building materials and other industries.

1.1 Purpose and advantages of the machine

1.1.1 Mainly used in organic fertilizers,

It can also be used in chemical metallurgy, mining, building materials and other industries under the dust collector of compound fertilizer and thermal power plant.

1.1.2 The advantages of a disc mixer are:

(1) It has high stirring efficiency and less floor space. The spiral blades are made of high wear-resistant special alloys.

(2) The disc mixer is driven by a reducer, with stable rotation and low noise.

(3) The disc mixer feeds from the top and discharges from the bottom, with a reasonable structure.

(4) The sealing between the joint surfaces is tight and the operation is stable.

-

The motor of the disc mixer drives the reducer to run, the reducer drives the main shaft, and the main shaft drives the stirring teeth to stir the materials.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry