Organic fertilizer drying equipment

- Production capacity: 0.5-30t/h

- Applicable materials: Drying of various poultry manures such as chicken manure, cow manure, pig manure, pigeon manure, etc.

- Applications: Drying of chicken manure, cow manure, pig manure, pigeon and other poultry excrement

Classification:

Tel:

Introduction

-

With the rapid development of intensive farms in the suburbs of large and medium cities, the pollution of livestock and poultry to the environment is becoming more and more serious. But poultry and livestock are also treasures

Expensive feed and fertilizer resources, if they can be exploited and utilized, will contribute to the development of the breeding industry and planting industry, save food and promote the increase of agricultural production.

Receipts are important. To this end, our company has developed a rapid drying equipment for livestock manure and a complete set of organic fertilizer production lines based on market conditions.

equipment.

The organic fertilizer production line includes extrusion granulator, counter-roll granulator, trommel screen, high-moisture material dryer, BB fertilizer blender, counter-roll compounder.

Fertilizer granulator, fermentation turner. BB fertilizer blending equipment, extrusion granulator, LP series chain crusher, multifunctional organic fertilizer (biological) spherical

Granulator, trommel screening machine, cage pulverizer, roller extrusion granulator, BB fertilizer production line

Organic fertilizer, chicken manure, cow manure, pig manure, duck manure,

The pigeon manure dryer (dryer) can directly dry up to 70%-80% moisture content to 13% safe storage moisture at one time.

It is carried out in a closed system, thereby reducing the pollution to the environment during the drying process. The equipment consists of combustion furnace, auger feeding device, drum crushing dryer, auger discharging device, dust removal device and smoke exhaust system.

-

The organic fertilizer dryer can directly dry livestock manure with a moisture content of up to 70%-80% to a safe initial moisture content of 13%. The whole process is closed.

It is carried out in the system, thereby reducing the pollution to the environment during the drying process. The equipment is mainly composed of heat source, feeder, feeder, rotary drum, discharge

It consists of a dryer, a material crushing device, an induced draft fan, an unloader and a power distribution cabinet; after the dehydrated wet material is added to the dryer, it is uniformly distributed in the drum.

When the plate is turned, the material is evenly dispersed in the dryer and fully contacted with the hot air, which speeds up the drying heat transfer and mass transfer. During the drying process, the

Under the action of the inclined copying plate and the hot gas, the material is discharged to the star-shaped discharge valve of the other section of the dryer to discharge the finished product.

-

Finished pellets

undefined

Features

-

- Commodity name: Organic fertilizer drying equipment

- Production capacity: 0.5-30t/h

- Applicable materials: Drying of various poultry manures such as chicken manure, cow manure, pig manure, pigeon manure, etc.

- Applications: Drying of chicken manure, cow manure, pig manure, pigeon and other poultry excrement

With the rapid development of intensive farms in the suburbs of large and medium cities, the pollution of livestock and poultry to the environment is becoming more and more serious. But poultry and livestock are also treasures

Expensive feed and fertilizer resources, if they can be exploited and utilized, will contribute to the development of the breeding industry and planting industry, save food and promote the increase of agricultural production.

Receipts are important. To this end, our company has developed a rapid drying equipment for livestock manure and a complete set of organic fertilizer production lines based on market conditions.

equipment.

The organic fertilizer production line includes extrusion granulator, counter-roll granulator, trommel screen, high-moisture material dryer, BB fertilizer blender, counter-roll compounder.

Fertilizer granulator, fermentation turner. BB fertilizer blending equipment, extrusion granulator, LP series chain crusher, multifunctional organic fertilizer (biological) spherical

Granulator, trommel screening machine, cage pulverizer, roller extrusion granulator, BB fertilizer production line

Organic fertilizer, chicken manure, cow manure, pig manure, duck manure,

The pigeon manure dryer (dryer) can directly dry up to 70%-80% moisture content to 13% safe storage moisture at one time.

It is carried out in a closed system, thereby reducing the pollution to the environment during the drying process. The equipment consists of combustion furnace, auger feeding device, drum crushing dryer, auger discharging device, dust removal device and smoke exhaust system.

-

The organic fertilizer dryer can directly dry livestock manure with a moisture content of up to 70%-80% to a safe initial moisture content of 13%. The whole process is closed.

It is carried out in the system, thereby reducing the pollution to the environment during the drying process. The equipment is mainly composed of heat source, feeder, feeder, rotary drum, discharge

It consists of a dryer, a material crushing device, an induced draft fan, an unloader and a power distribution cabinet; after the dehydrated wet material is added to the dryer, it is uniformly distributed in the drum.

When the plate is turned, the material is evenly dispersed in the dryer and fully contacted with the hot air, which speeds up the drying heat transfer and mass transfer. During the drying process, the

Under the action of the inclined copying plate and the hot gas, the material is discharged to the star-shaped discharge valve of the other section of the dryer to discharge the finished product.

-

Working Principle

-

- Commodity name: Organic fertilizer drying equipment

- Production capacity: 0.5-30t/h

- Applicable materials: Drying of various poultry manures such as chicken manure, cow manure, pig manure, pigeon manure, etc.

- Applications: Drying of chicken manure, cow manure, pig manure, pigeon and other poultry excrement

With the rapid development of intensive farms in the suburbs of large and medium cities, the pollution of livestock and poultry to the environment is becoming more and more serious. But poultry and livestock are also treasures

Expensive feed and fertilizer resources, if they can be exploited and utilized, will contribute to the development of the breeding industry and planting industry, save food and promote the increase of agricultural production.

Receipts are important. To this end, our company has developed a rapid drying equipment for livestock manure and a complete set of organic fertilizer production lines based on market conditions.

equipment.

The organic fertilizer production line includes extrusion granulator, counter-roll granulator, trommel screen, high-moisture material dryer, BB fertilizer blender, counter-roll compounder.

Fertilizer granulator, fermentation turner. BB fertilizer blending equipment, extrusion granulator, LP series chain crusher, multifunctional organic fertilizer (biological) spherical

Granulator, trommel screening machine, cage pulverizer, roller extrusion granulator, BB fertilizer production line

Organic fertilizer, chicken manure, cow manure, pig manure, duck manure,

The pigeon manure dryer (dryer) can directly dry up to 70%-80% moisture content to 13% safe storage moisture at one time.

It is carried out in a closed system, thereby reducing the pollution to the environment during the drying process. The equipment consists of combustion furnace, auger feeding device, drum crushing dryer, auger discharging device, dust removal device and smoke exhaust system.

-

The organic fertilizer dryer can directly dry livestock manure with a moisture content of up to 70%-80% to a safe initial moisture content of 13%. The whole process is closed.

It is carried out in the system, thereby reducing the pollution to the environment during the drying process. The equipment is mainly composed of heat source, feeder, feeder, rotary drum, discharge

It consists of a dryer, a material crushing device, an induced draft fan, an unloader and a power distribution cabinet; after the dehydrated wet material is added to the dryer, it is uniformly distributed in the drum.

When the plate is turned, the material is evenly dispersed in the dryer and fully contacted with the hot air, which speeds up the drying heat transfer and mass transfer. During the drying process, the

Under the action of the inclined copying plate and the hot gas, the material is discharged to the star-shaped discharge valve of the other section of the dryer to discharge the finished product.

-

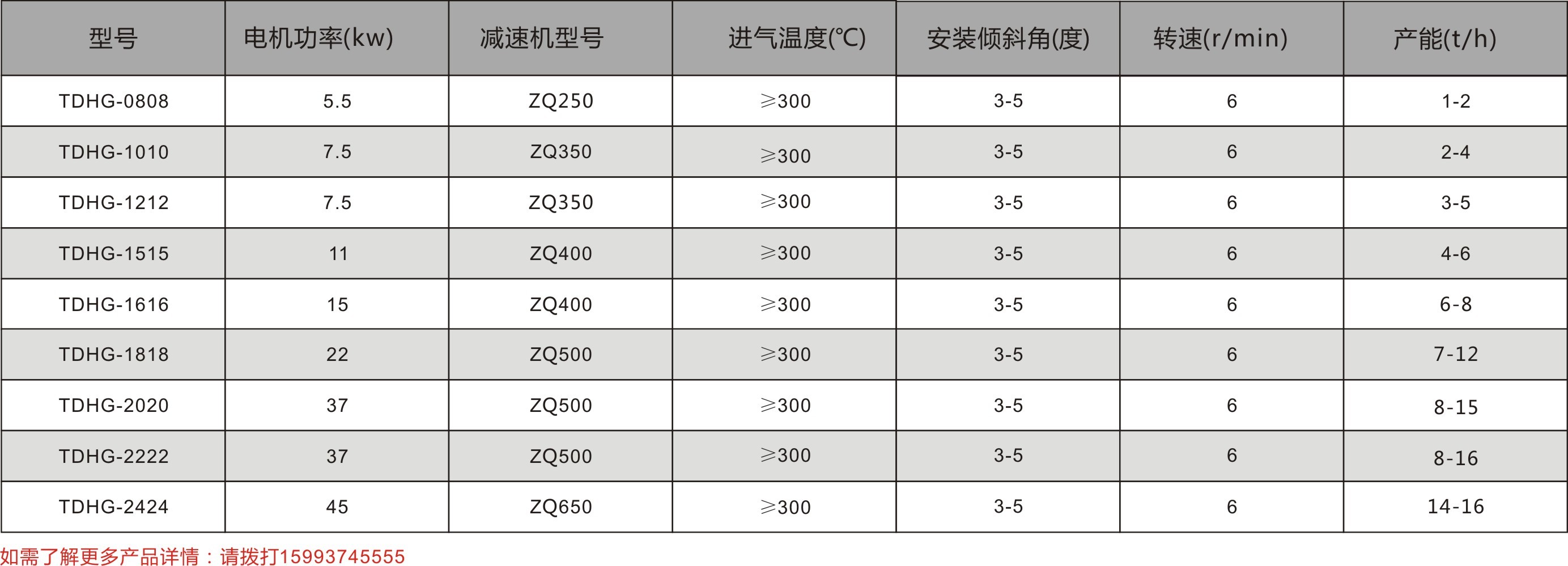

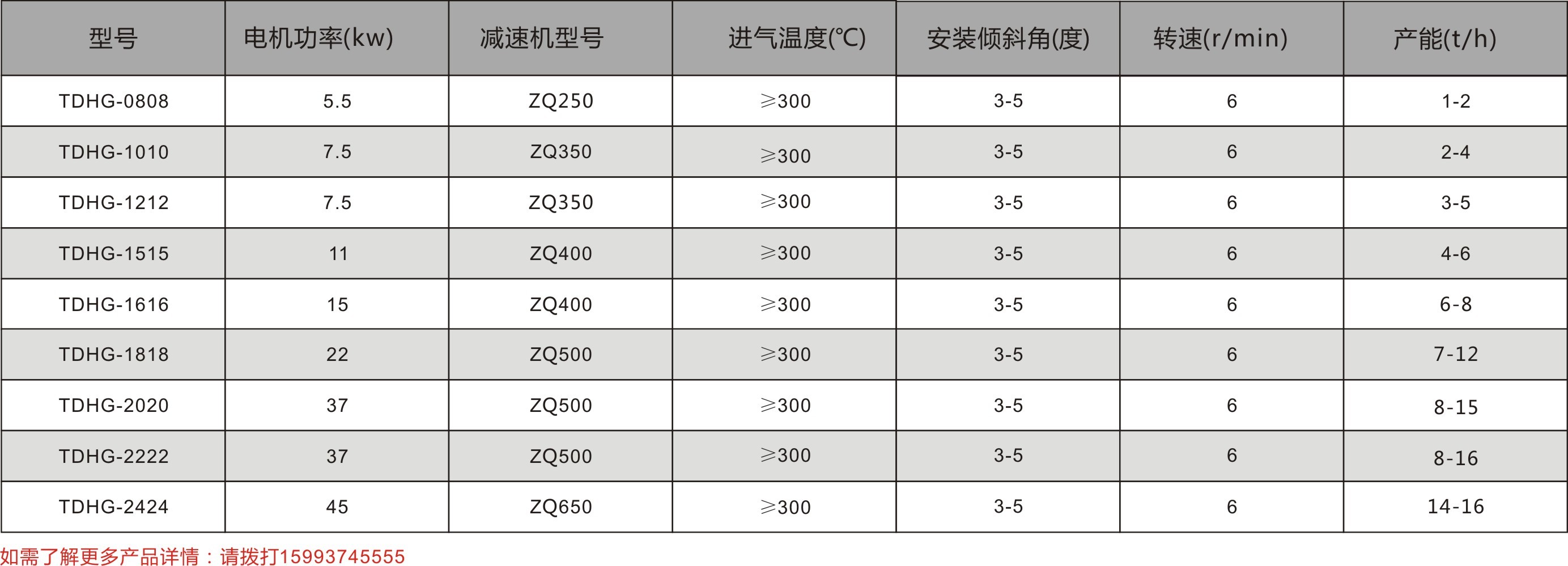

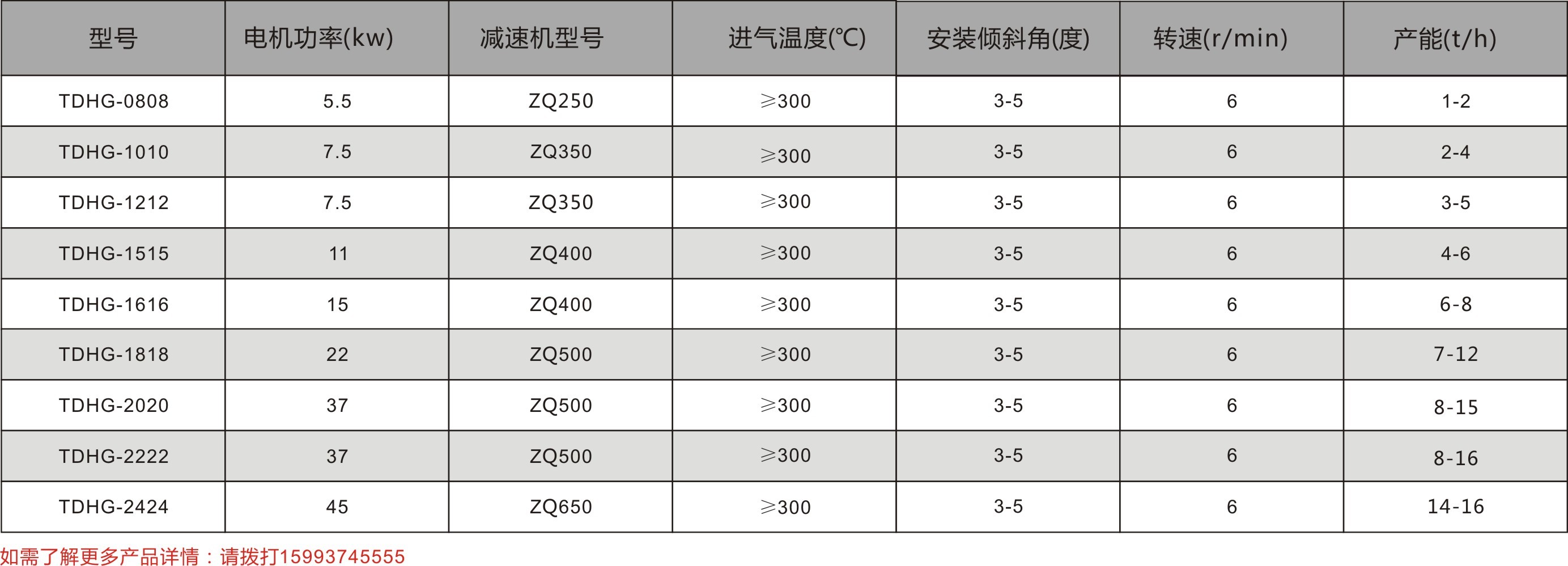

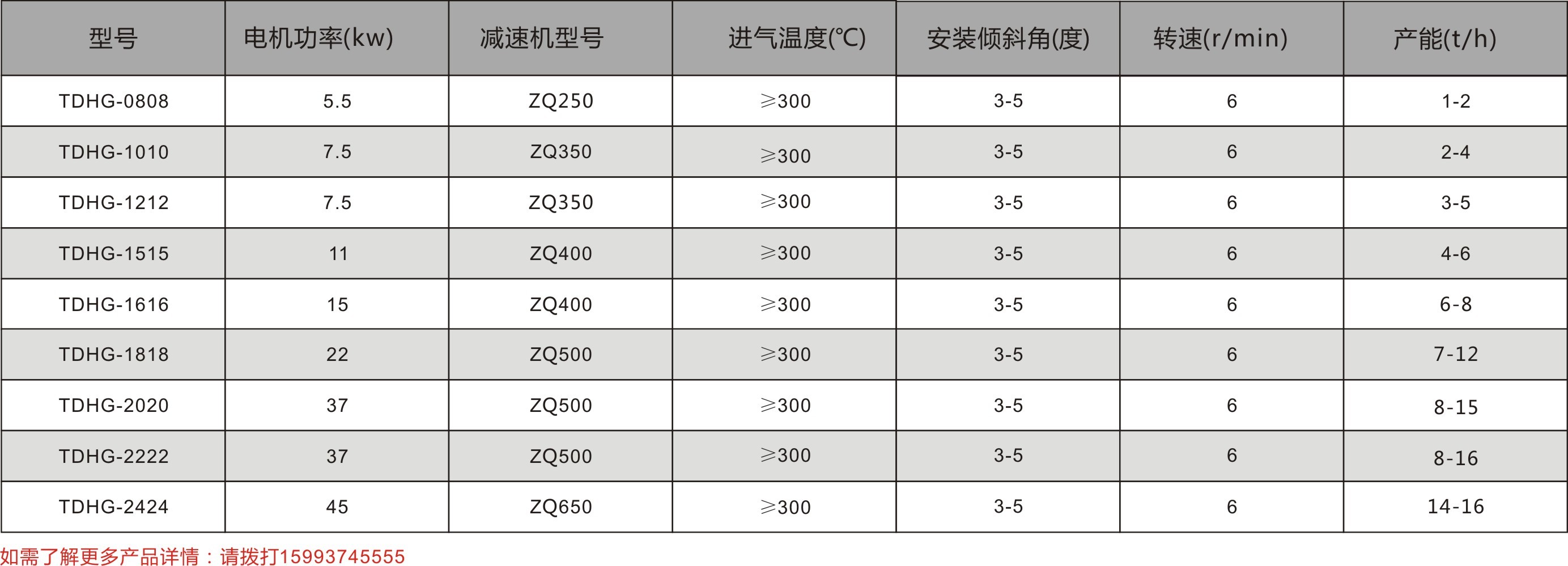

Technical parameters

-

- Commodity name: Organic fertilizer drying equipment

- Production capacity: 0.5-30t/h

- Applicable materials: Drying of various poultry manures such as chicken manure, cow manure, pig manure, pigeon manure, etc.

- Applications: Drying of chicken manure, cow manure, pig manure, pigeon and other poultry excrement

With the rapid development of intensive farms in the suburbs of large and medium cities, the pollution of livestock and poultry to the environment is becoming more and more serious. But poultry and livestock are also treasures

Expensive feed and fertilizer resources, if they can be exploited and utilized, will contribute to the development of the breeding industry and planting industry, save food and promote the increase of agricultural production.

Receipts are important. To this end, our company has developed a rapid drying equipment for livestock manure and a complete set of organic fertilizer production lines based on market conditions.

equipment.

The organic fertilizer production line includes extrusion granulator, counter-roll granulator, trommel screen, high-moisture material dryer, BB fertilizer blender, counter-roll compounder.

Fertilizer granulator, fermentation turner. BB fertilizer blending equipment, extrusion granulator, LP series chain crusher, multifunctional organic fertilizer (biological) spherical

Granulator, trommel screening machine, cage pulverizer, roller extrusion granulator, BB fertilizer production line

Organic fertilizer, chicken manure, cow manure, pig manure, duck manure,

The pigeon manure dryer (dryer) can directly dry up to 70%-80% moisture content to 13% safe storage moisture at one time.

It is carried out in a closed system, thereby reducing the pollution to the environment during the drying process. The equipment consists of combustion furnace, auger feeding device, drum crushing dryer, auger discharging device, dust removal device and smoke exhaust system.

-

The organic fertilizer dryer can directly dry livestock manure with a moisture content of up to 70%-80% to a safe initial moisture content of 13%. The whole process is closed.

It is carried out in the system, thereby reducing the pollution to the environment during the drying process. The equipment is mainly composed of heat source, feeder, feeder, rotary drum, discharge

It consists of a dryer, a material crushing device, an induced draft fan, an unloader and a power distribution cabinet; after the dehydrated wet material is added to the dryer, it is uniformly distributed in the drum.

When the plate is turned, the material is evenly dispersed in the dryer and fully contacted with the hot air, which speeds up the drying heat transfer and mass transfer. During the drying process, the

Under the action of the inclined copying plate and the hot gas, the material is discharged to the star-shaped discharge valve of the other section of the dryer to discharge the finished product.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry