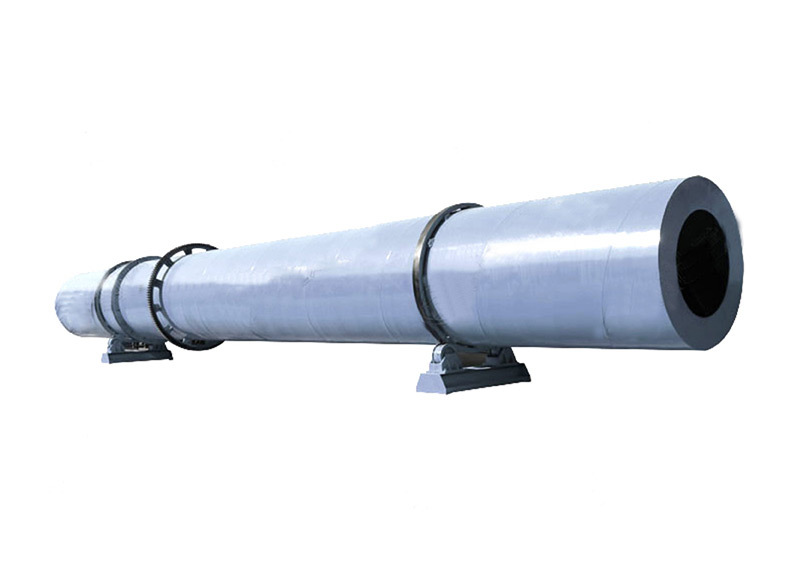

Tumble dryer

- Production capacity: 1-45t/h

- Applicable materials: Coal slurry, lignite, mineral powder, slag, ore, mineral sand, wine dregs, sawdust, fruit dregs, soybean dregs, sugar dregs, wood bran, chicken manure, cow manure, organic fertilizer, kaolin, etc.

- Applications: Widely used in metallurgy, building materials, chemical industry, coal washing, chemical fertilizer, ore, sand, clay, kaolin, sugar and other fields

Classification:

Tel:

Introduction

-

The tumble dryer is one of the traditional drying equipment. The equipment is reliable in operation, flexible in operation, strong in adaptability and large in processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar, etc. Field, straight length: Φ1000-94000, the length depends on the requirements of dry hair. In the center of the tumble dryer, it can be avoided to add a dispersing mechanism. The wet material entering the drying cylinder is repeatedly picked up by the copying board on the wall of the rotary dryer, dropped, and is broken into fine particles by the dispersing device during the falling too short. , the specific area is greatly increased, and it is fully contacted with hot air and dried.

-

The tumble dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The dry wet material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly.

The dryer cylinder is a rotating cylinder slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end, and is in countercurrent contact with the material, and some heat carrier and material flow into the cylinder together. With the rotation of the circle, the material runs to the bottom end by gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly supplied by the heat carrier, so that the wet material is dried, and then sent out through a belt conveyor or a screw conveyor at the discharge end.

-

Finished pellets

undefined

Features

-

- Commodity name: Tumble dryer

- Production capacity: 1-45t/h

- Applicable materials: Coal slurry, lignite, mineral powder, slag, ore, mineral sand, wine dregs, sawdust, fruit dregs, soybean dregs, sugar dregs, wood bran, chicken manure, cow manure, organic fertilizer, kaolin, etc.

- Applications: Widely used in metallurgy, building materials, chemical industry, coal washing, chemical fertilizer, ore, sand, clay, kaolin, sugar and other fields

The tumble dryer is one of the traditional drying equipment. The equipment is reliable in operation, flexible in operation, strong in adaptability and large in processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar, etc. Field, straight length: Φ1000-94000, the length depends on the requirements of dry hair. In the center of the tumble dryer, it can be avoided to add a dispersing mechanism. The wet material entering the drying cylinder is repeatedly picked up by the copying board on the wall of the rotary dryer, dropped, and is broken into fine particles by the dispersing device during the falling too short. , the specific area is greatly increased, and it is fully contacted with hot air and dried.

-

The tumble dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The dry wet material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly.

The dryer cylinder is a rotating cylinder slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end, and is in countercurrent contact with the material, and some heat carrier and material flow into the cylinder together. With the rotation of the circle, the material runs to the bottom end by gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly supplied by the heat carrier, so that the wet material is dried, and then sent out through a belt conveyor or a screw conveyor at the discharge end.

-

Working Principle

-

- Commodity name: Tumble dryer

- Production capacity: 1-45t/h

- Applicable materials: Coal slurry, lignite, mineral powder, slag, ore, mineral sand, wine dregs, sawdust, fruit dregs, soybean dregs, sugar dregs, wood bran, chicken manure, cow manure, organic fertilizer, kaolin, etc.

- Applications: Widely used in metallurgy, building materials, chemical industry, coal washing, chemical fertilizer, ore, sand, clay, kaolin, sugar and other fields

The tumble dryer is one of the traditional drying equipment. The equipment is reliable in operation, flexible in operation, strong in adaptability and large in processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar, etc. Field, straight length: Φ1000-94000, the length depends on the requirements of dry hair. In the center of the tumble dryer, it can be avoided to add a dispersing mechanism. The wet material entering the drying cylinder is repeatedly picked up by the copying board on the wall of the rotary dryer, dropped, and is broken into fine particles by the dispersing device during the falling too short. , the specific area is greatly increased, and it is fully contacted with hot air and dried.

-

The tumble dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The dry wet material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly.

The dryer cylinder is a rotating cylinder slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end, and is in countercurrent contact with the material, and some heat carrier and material flow into the cylinder together. With the rotation of the circle, the material runs to the bottom end by gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly supplied by the heat carrier, so that the wet material is dried, and then sent out through a belt conveyor or a screw conveyor at the discharge end.

-

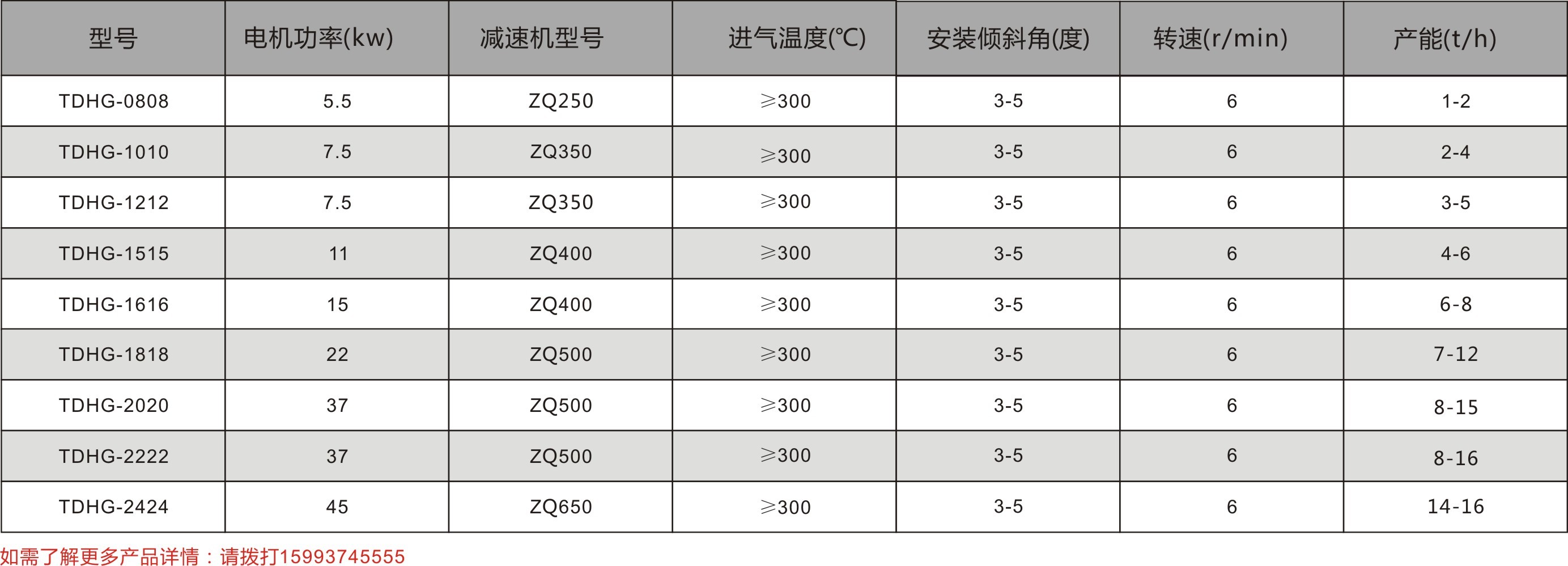

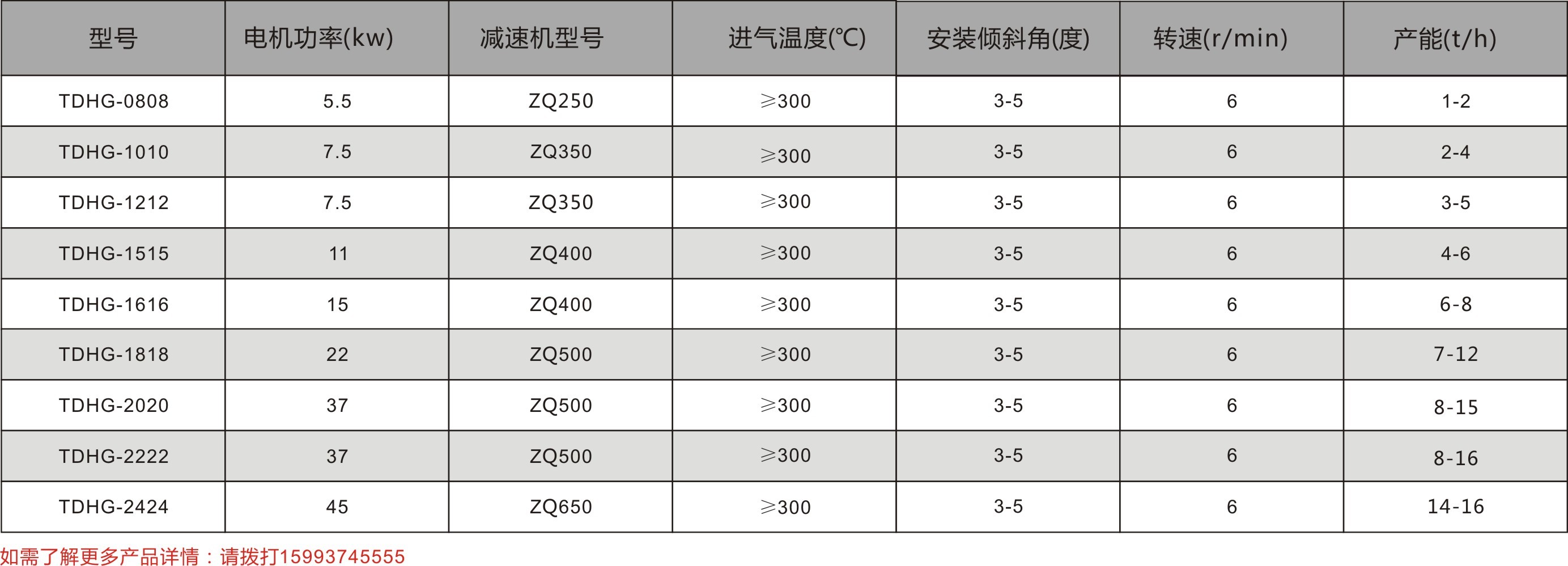

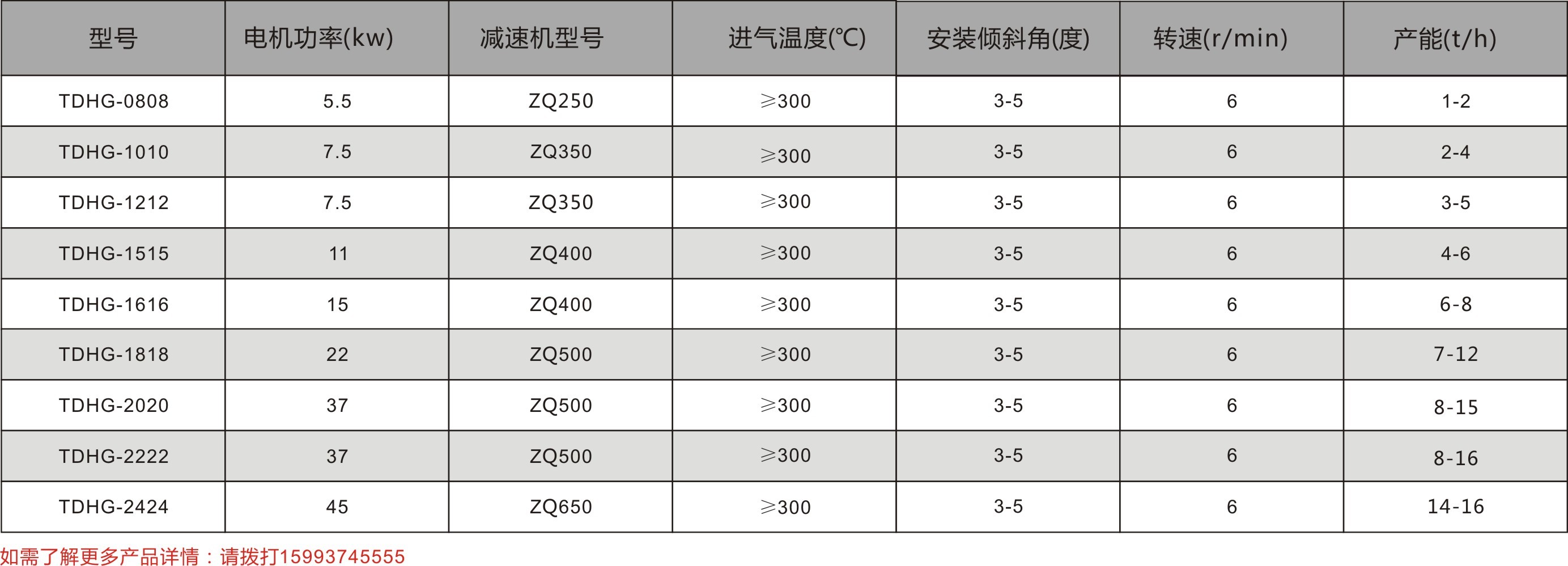

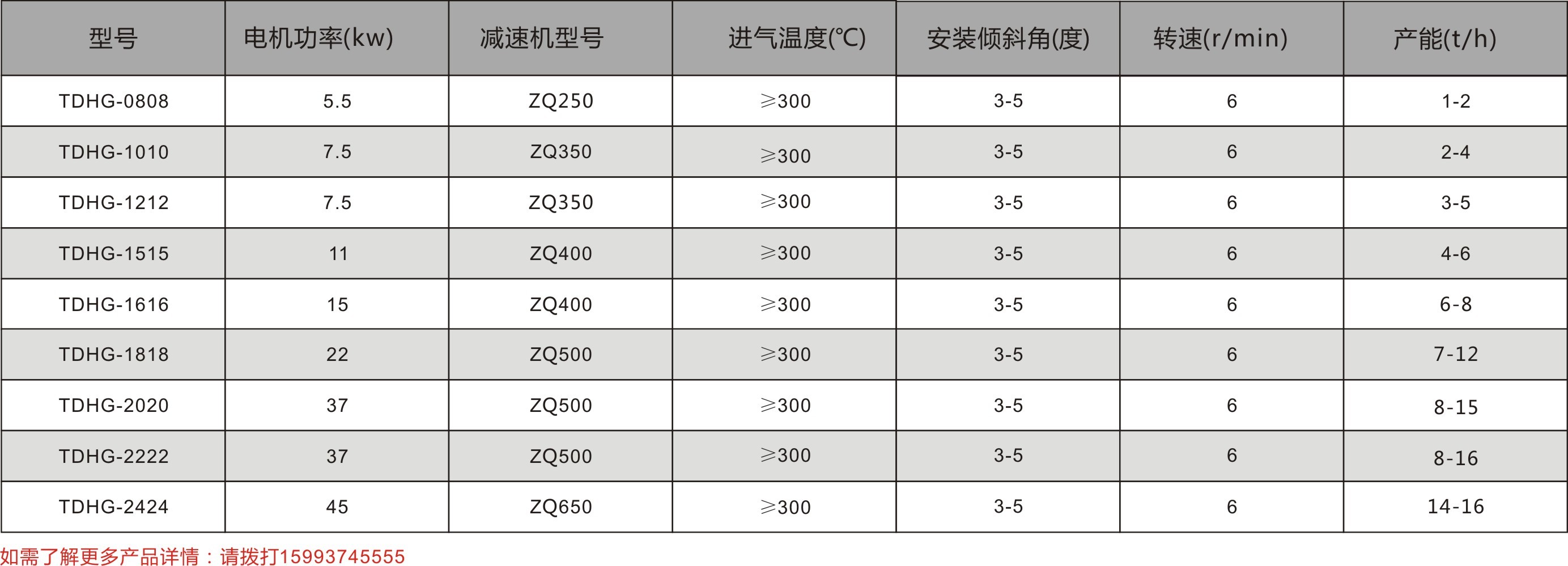

Technical parameters

-

- Commodity name: Tumble dryer

- Production capacity: 1-45t/h

- Applicable materials: Coal slurry, lignite, mineral powder, slag, ore, mineral sand, wine dregs, sawdust, fruit dregs, soybean dregs, sugar dregs, wood bran, chicken manure, cow manure, organic fertilizer, kaolin, etc.

- Applications: Widely used in metallurgy, building materials, chemical industry, coal washing, chemical fertilizer, ore, sand, clay, kaolin, sugar and other fields

The tumble dryer is one of the traditional drying equipment. The equipment is reliable in operation, flexible in operation, strong in adaptability and large in processing capacity. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, sugar, etc. Field, straight length: Φ1000-94000, the length depends on the requirements of dry hair. In the center of the tumble dryer, it can be avoided to add a dispersing mechanism. The wet material entering the drying cylinder is repeatedly picked up by the copying board on the wall of the rotary dryer, dropped, and is broken into fine particles by the dispersing device during the falling too short. , the specific area is greatly increased, and it is fully contacted with hot air and dried.

-

The tumble dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The dry wet material is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly.

The dryer cylinder is a rotating cylinder slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end, and is in countercurrent contact with the material, and some heat carrier and material flow into the cylinder together. With the rotation of the circle, the material runs to the bottom end by gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly supplied by the heat carrier, so that the wet material is dried, and then sent out through a belt conveyor or a screw conveyor at the discharge end.

-

Tel:

Related Equipment

Organic fertilizer production line

Slag name

Organic fertilizer and detailed text

Water soluble fertilizer

Inquiry